Hoisting device for automatic equipment installation

A technology of automation equipment and lifting devices, which is applied in the direction of lifting equipment braking devices, safety devices, hoisting devices, etc., can solve the problems of high cost and power consumption, and achieve acceleration and stop, strong magnetic force, and increased inertia. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

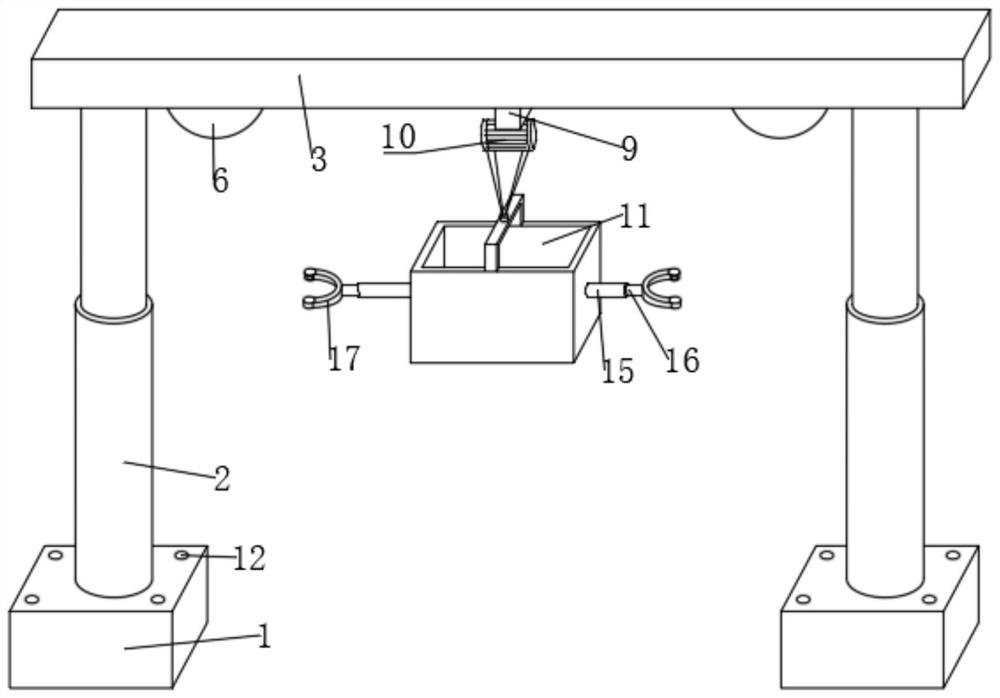

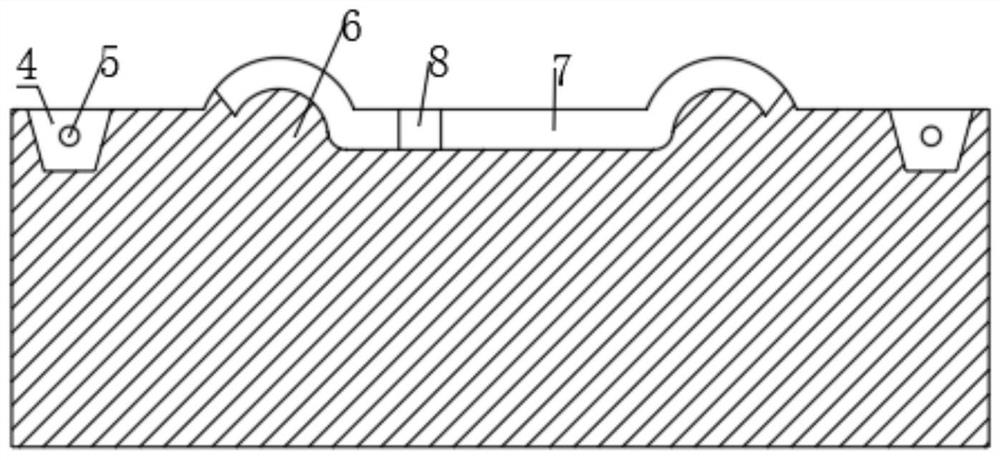

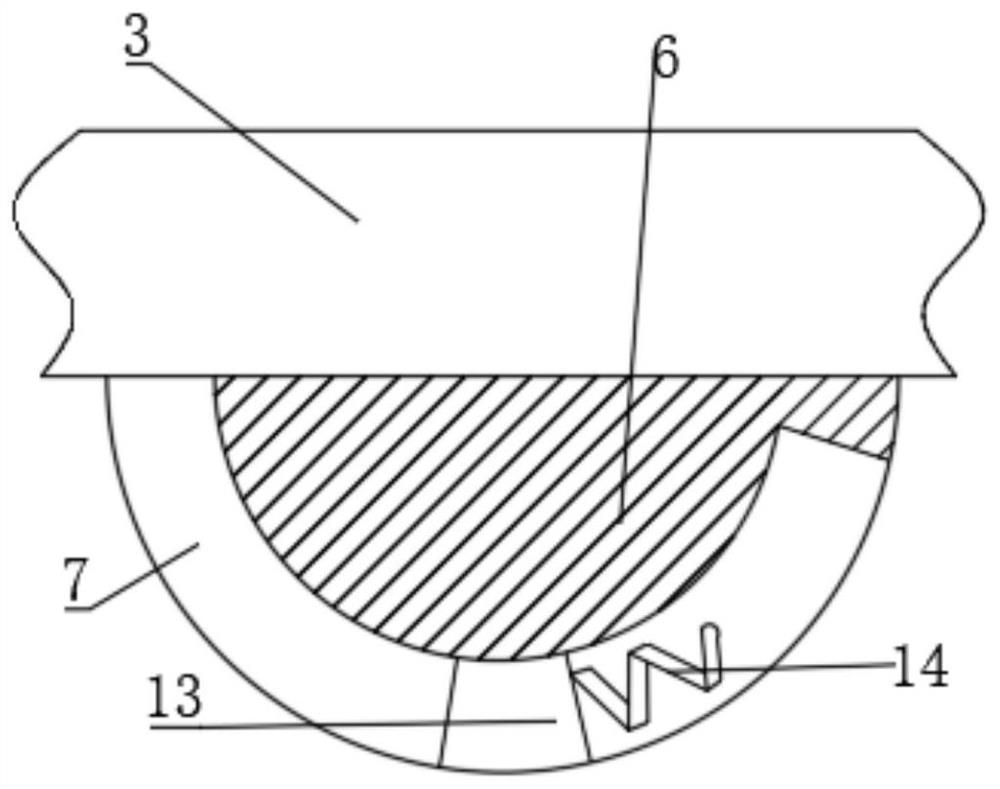

[0026] refer to Figure 1-3 , a hoisting device for installing automation equipment, comprising two bases 1, a hydraulic cylinder is fixed inside the base 1 by bolts, a hydraulic rod 2 is connected to the output end of the hydraulic cylinder, the hydraulic rod 2 and the base 1 are set through, and the two hydraulic rods 2 is set above the same lifting beam 3, and two notches 4 are symmetrically opened on both sides of the bottom of the lifting beam 3, and the notches 4 are set in a flared structure, and the straight shaft 5 is fixed in the notch 4 by bolts, and the hydraulic rod 2. The output shaft and the straight shaft 5 are nested and flexibly connected. Two deceleration bumps 6 are welded symmetrically on both sides of the bottom of the lifting beam 3. The deceleration bump 6 and the bottom of the inner wall of the lifting beam 3 are provided with the same first chute 7. The cross-section of the first chute 7 located on the deceleration bump 6 is set in an arc shape. The f...

Embodiment 2

[0030] refer to Figure 1-5 , a lifting device for the installation of automation equipment, 4 the first chute 7 is slidingly connected with a block 13, the outside of the block 13 is fixed with a first spring 14 by bolts, and the anti-collision mechanism passes symmetrically on both sides of the lifting box 11 Bolts are fixed with two sleeves 15, the sleeves 15 are sleeved with an inner rod 16, and the outer side of the inner rod 16 is bonded with a speed-reducing claw 17, which is made of rubber material, and the speed-reducing claw 17 is arranged as a fork structure The deceleration mechanism is provided with an embedded groove 18 in the casing 15, the inner rod 16 is arranged in the embedded groove 18, the bottom of the inner wall of the embedded groove 18 is fixed with a second spring 19 by bolts, and the top of the second spring 19 and the bottom of the inner rod 16 are welded and fixed The inner wall of one side of the embedded groove 18 is provided with a second chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com