Stainless steel ignition rod for stove

A technology of stainless steel and ignition rods, applied in the direction of combustion ignition, incandescent ignition, combustion methods, etc., can solve the problems of ignition rods without protective function and poor safety performance, and achieve the effects of avoiding playing ignition, strong practicability, and avoiding sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

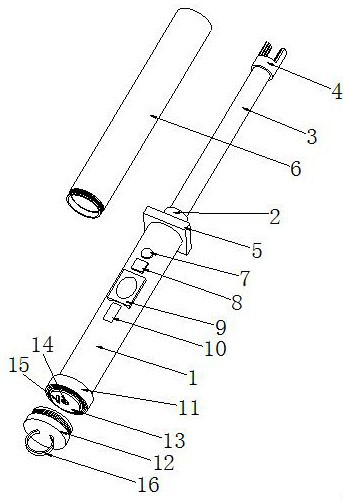

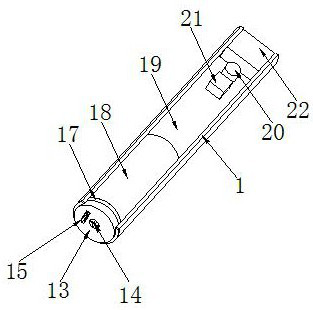

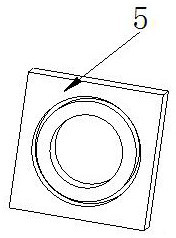

[0023] see Figure 1-3 , the present invention provides the following technical solutions: a stainless steel ignition rod for a stove, including a handle 1, one end of the handle 1 is fixedly connected with a connection block 2, and the connection block 2 is fixedly connected with an ignition rod 3, and one end of the ignition rod 3 is fixed It is connected with an ignition head 4, and the connection block 2 is fixedly connected with an anti-roll block 5, and the anti-roll block 5 is threadedly connected with a rod cover 6, and the handle 1 is provided with an ignition button 7, and one side of the ignition button 7 is provided with a power button 8, and the power supply One side of the button 8 is provided with a fingerprint reader 9, and one side of the fingerprint reader 9 is provided with a battery indicator 10. The bottom end of the handle 1 is fixedly connected with a mounting block 11, and the internal thread of the mounting block 11 is connected with a connecting block ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap