Galvanized steel sheet defective pixel detection device

A technology of galvanized steel sheet and detection device, which is used in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc. problems, to achieve the effect of improving the dead spot detection device and technology of galvanized steel sheets, reducing production costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

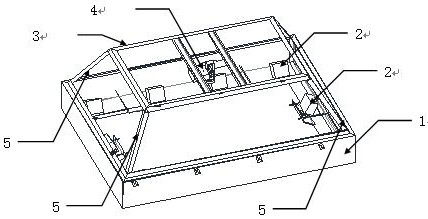

[0033] Such as figure 1 As shown, a galvanized steel sheet defect detection device includes:

[0034] lighting device installation frame 1, used for installing lighting device,

[0035] The camera installation frame 3 is used to install the camera 4,

[0036] The connecting member 5 connects the lighting device installation frame 1 and the shooting device installation frame 3 into one, and the lighting device is closer to the object to be photographed than the shooting device 4,

[0037] The detection device is placed in the galvanized steel plate detection section, preferably placed above the mesh belt conveyor, for collecting surface appearance images of galvanized steel plates, and the surface appearance images are output to a computer for image detection, and the computer outputs detection target information and position information. The detection target refers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com