Online rapid detection system and analysis and detection method for grain composition analysis of spiral-flow type machine-made sand

A detection system, a technology of machine-made sand, which is applied in the analysis of materials, by removing certain components, weighing, instruments, etc., can solve the problems of poor identification accuracy and poor identification efficiency of weighing equipment, and achieve reliable results and detection results. Reliable, uniquely calculated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

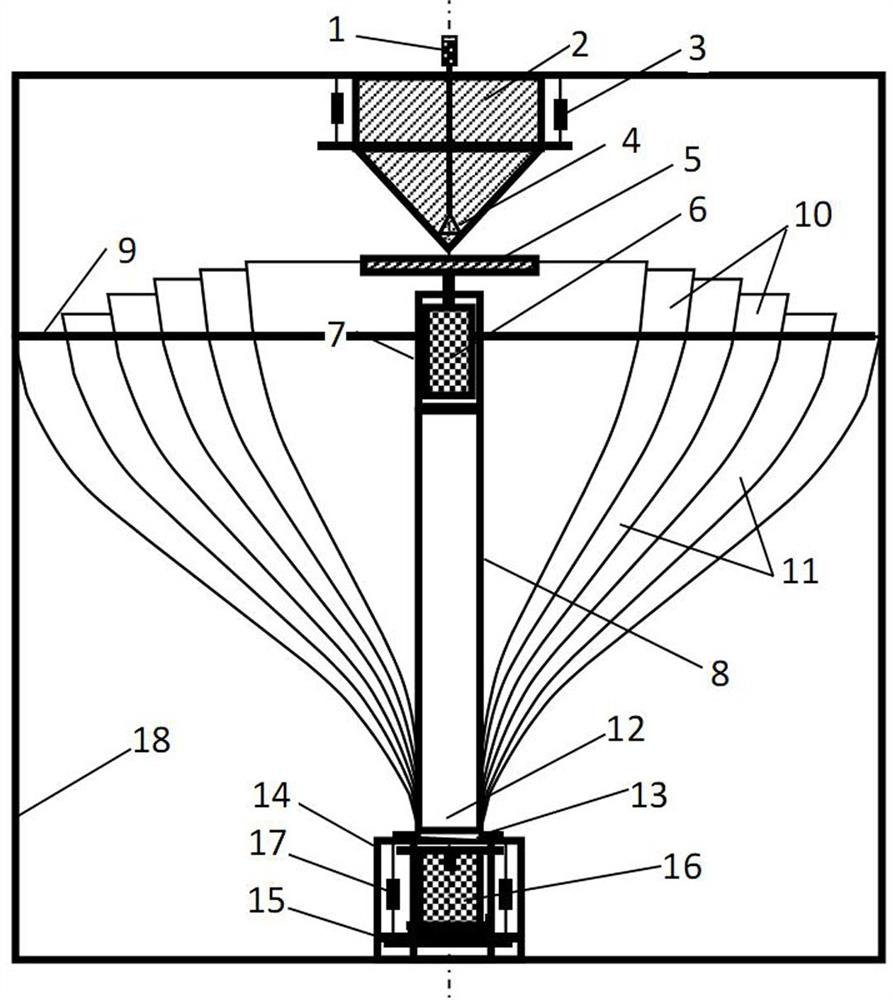

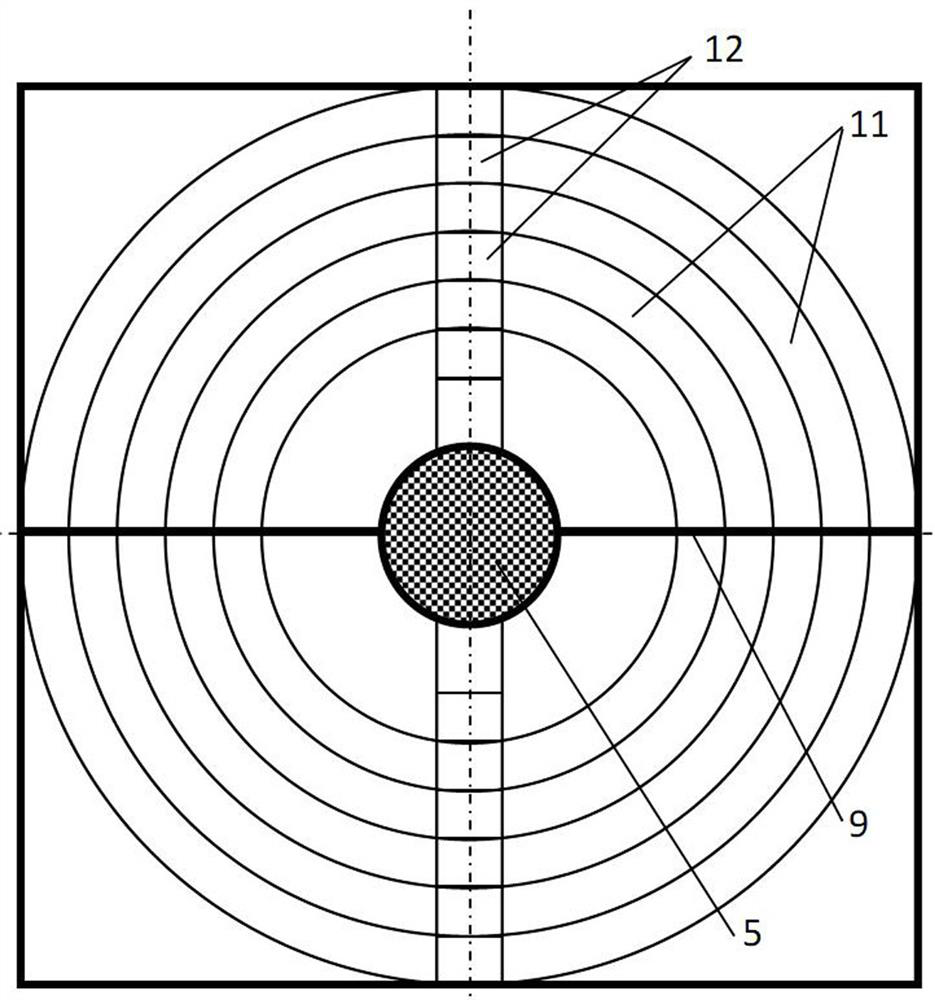

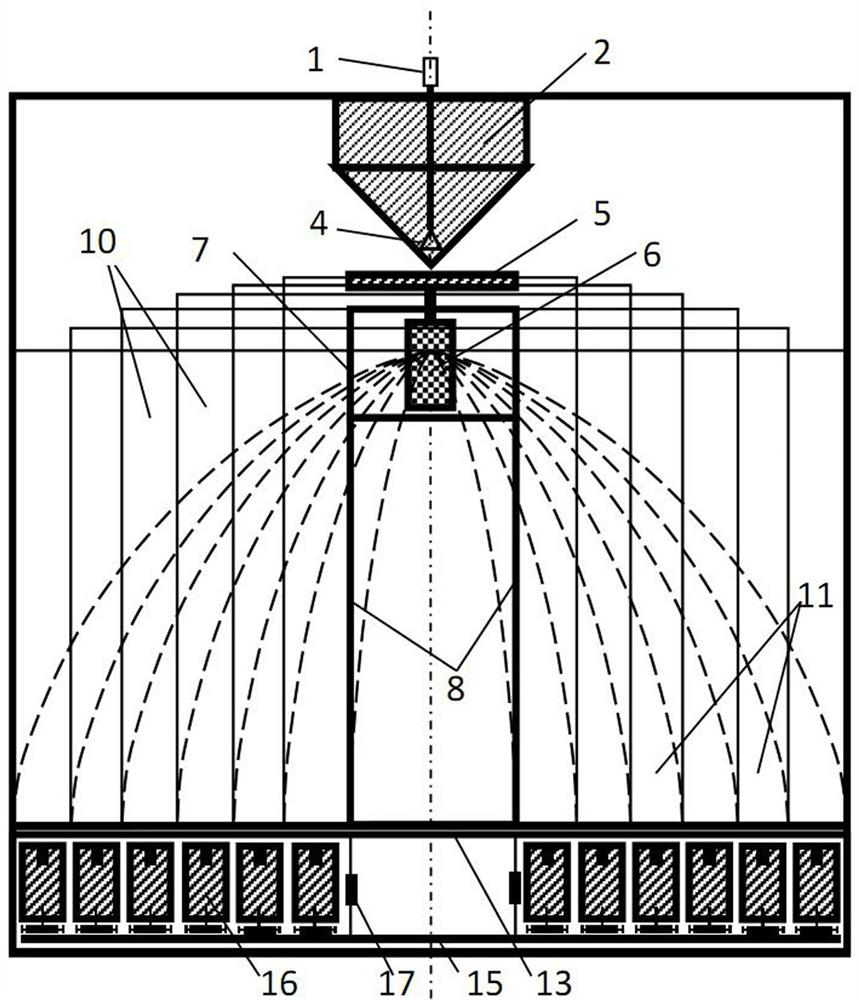

[0039] An online rapid detection system for particle gradation analysis of swirling machine-made sand, see Figure 1 to Figure 4, including the blanking control device installed in the outer frame 18, the rotary material spreading device, the sand classification collection device, the sand classification weighing device and the control system, after the rotary material distribution device accepts the quantitative blanking of the blanking control device, the uniform speed Turn the throwing material to realize the grade division in the sand material grading and weighing device, and finally realize rapid detection with the cooperation of the control system;

[0040] The blanking control device includes a hopper 2, a micro motor that controls the opening and closing of the valve at the bottom of the hopper 2, and a weighing sensor 3 that measures the load of the hopper 2;

[0041] The rotating material spreading device comprises a material spreading turntable (5) below the valve a...

Embodiment 2

[0057] The principle of this embodiment is the same as that of Embodiment 1, except that the number of helical turns of the rotating channel is 0.5, and the helical channels are evenly distributed relative to the circumference of the material distribution cylinder 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com