A path planning method for pcb board dispensing process

A PCB board and dispensing process technology, which is applied to the surface coating liquid device, program control, electrical program control, etc., can solve the problems of long dispensing time, insufficient dispensing effect, lack of dispensing movement path, etc. Achieve the effects of preventing crossing, improving dispensing processing efficiency, and saving dispensing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

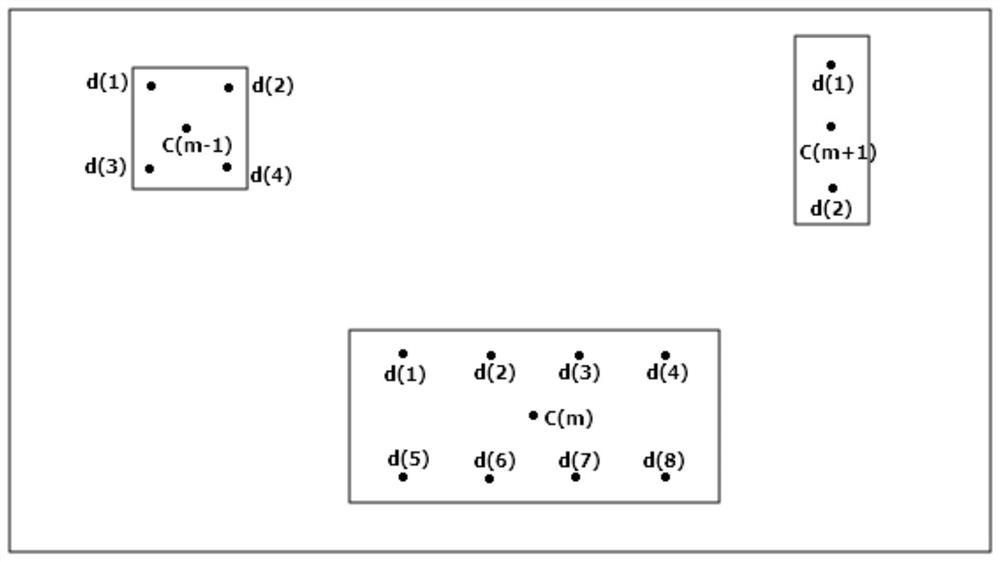

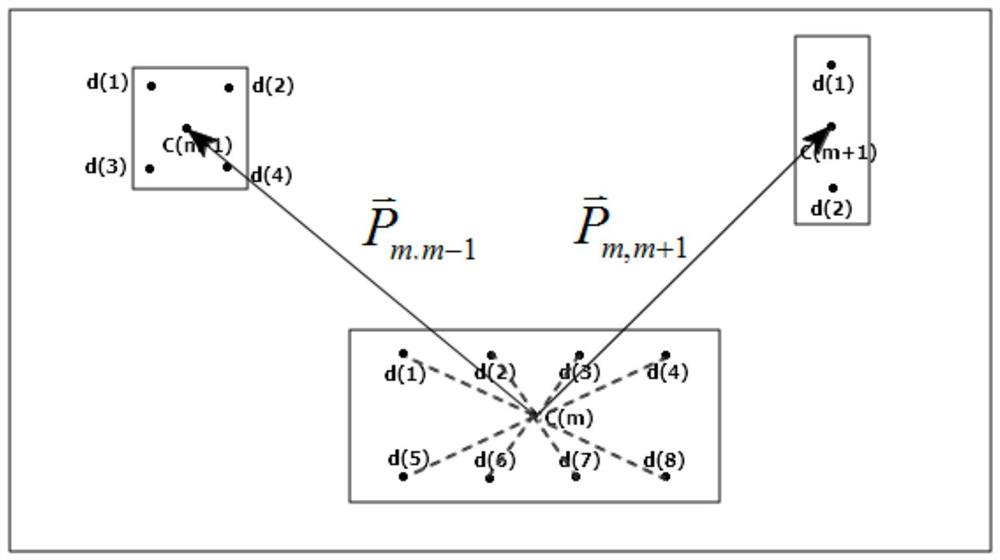

[0039] Step 1, see figure 1 , according to the Gerber file of the PCB, the center coordinate position C and the rotation angle R of the components on the PCB are obtained;

[0040] Step 2. Determine the coordinates of the dispensing position of each type of component relative to the center C of the component through the red glue process standard or experience, d(1), d(2),...,d(h) ,See figure 1 , for all components on the PCB board, a series of disjointed dispensing points can be obtained;

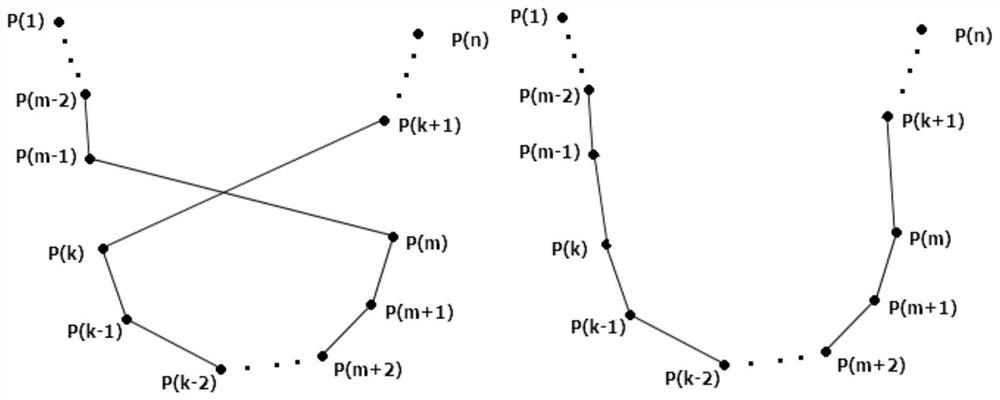

[0041] Step 3, assuming that the center points of components C(1), C(2), C(3),...C(n) are expressed as C{n}, use the sorting algorithm to sort all the The center points of the components are sorted to obtain a component sorting Cs{n}; the specific sorting algorithm used is:

[0042] Assume that given any series of points to be sorted, whose coordinates are P(1), P(2), P(3),...P(n), define:

[0043] 1. |P(1)P(2)| is the distance between the center points of two components;

[0044] 2. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com