Torsional vibration damper, clutch disc, and clutch

A torsional vibration damper, clutch plate technology, applied in the direction of shock absorber, spring/shock absorber design features, spring/shock absorber, etc. Shock absorber durability issues, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

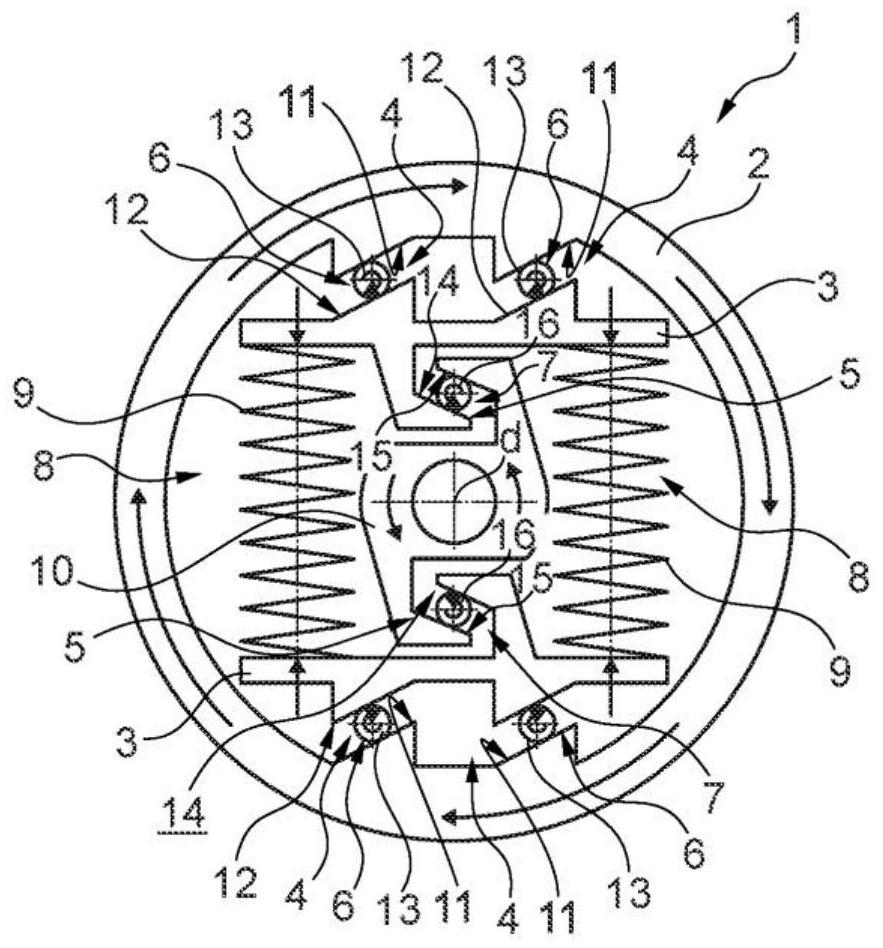

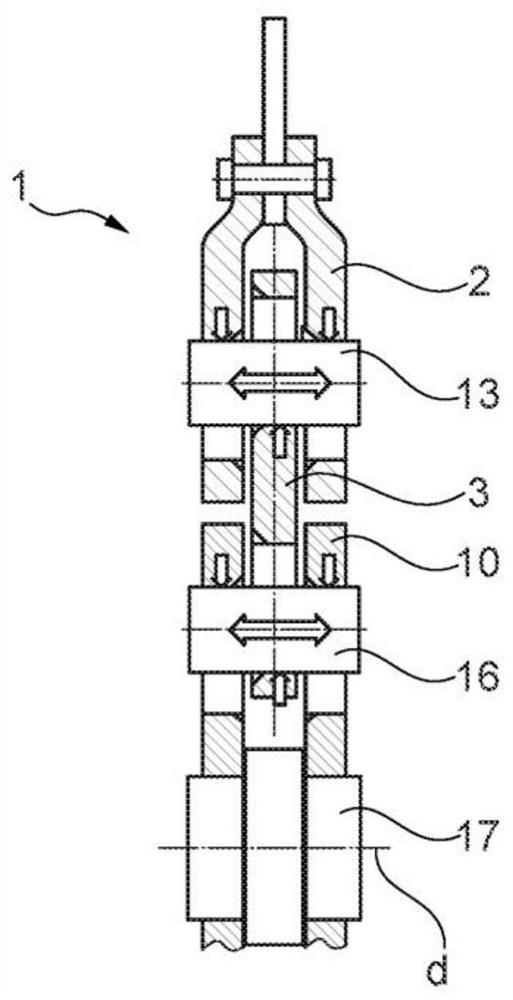

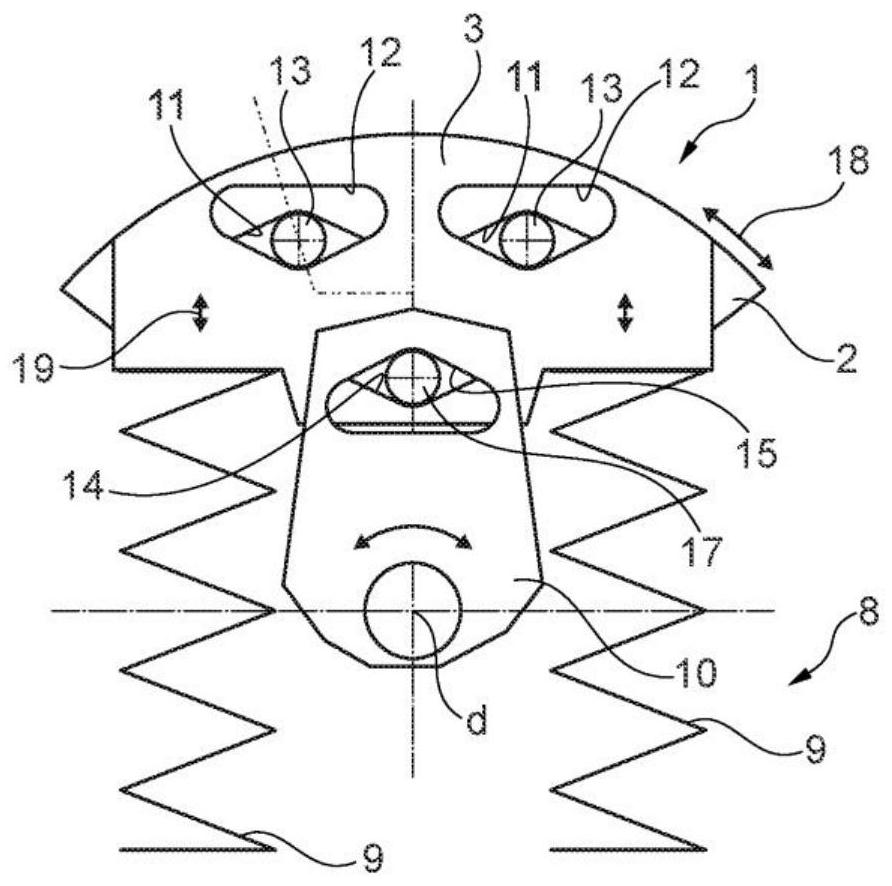

[0029] In the description of the figures, the same parts are provided with the same reference numerals. known as figure 1 and figure 2 The torsional vibration damper 1 shown in includes an input part 2, an intermediate element 3, a cam mechanism 4, 5 with a ramp arrangement 6, 7 and a spring arrangement 8 with an energy store 9 arranged at Between the intermediate element 3 and the output member 10 . figure 1 The input part 2 of the torsional vibration damper 1 has a slope 11, such as the cam track of the slope device 6 in preferably two cam mechanisms 4 that are mutually relative to the axis of rotation d of the shaft 17 relatively. Preferably, two mutually opposite intermediate elements 3 and rolling elements 13 form a complete cam mechanism 4 between the input piece 2 and the intermediate element 3, said two mutually opposite intermediate elements each having two complementary to the input piece 2. A ramp 12, such as a cam track of the ramp device 6. When the input pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com