Termite detecting, trapping and killing device

A termite and support rod technology, used in hunting equipment, applications, animal husbandry, etc., can solve the problems of hard soil in river dams and difficult to excavate, ant control devices cannot reach the vicinity of ant nests, and black-winged soil termites cannot be trapped and killed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

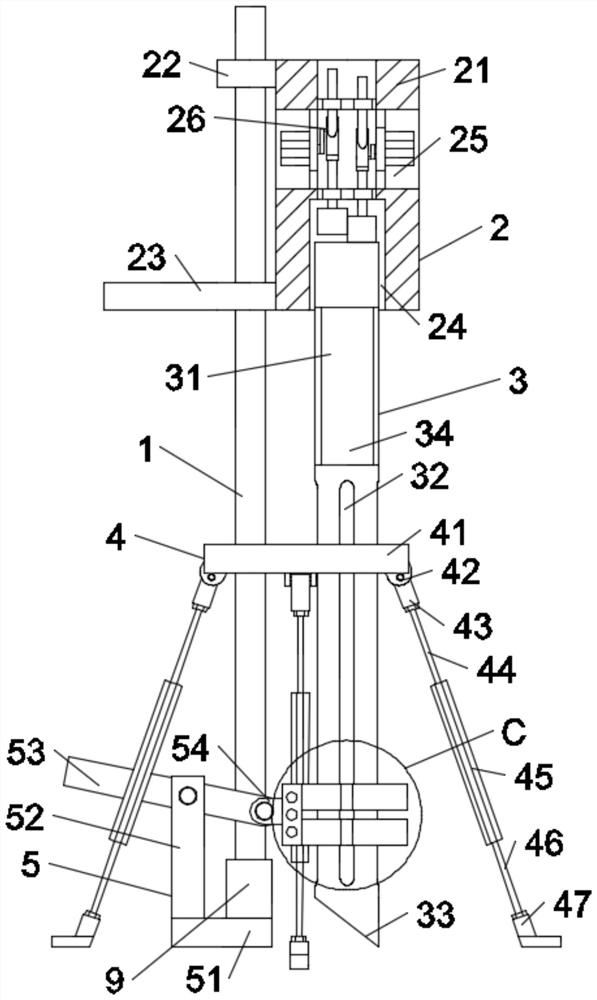

[0025] Such as Figure 1-Figure 7 As shown, in the embodiment of the present invention, a termite detection and trapping device includes a vertical support rod 1, the upper section of the vertical support rod 1 is slidably connected with a knocking device 2, and the knocking device 2 is connected with a casing 3. The middle section of the vertical support rod 1 is slidably connected with a triangular support frame 4, and the bottom end of the vertical support rod 1 is set on the support rod seat 9, and the support rod seat 9 is fixed on the foot-operated pull-out device 5 .

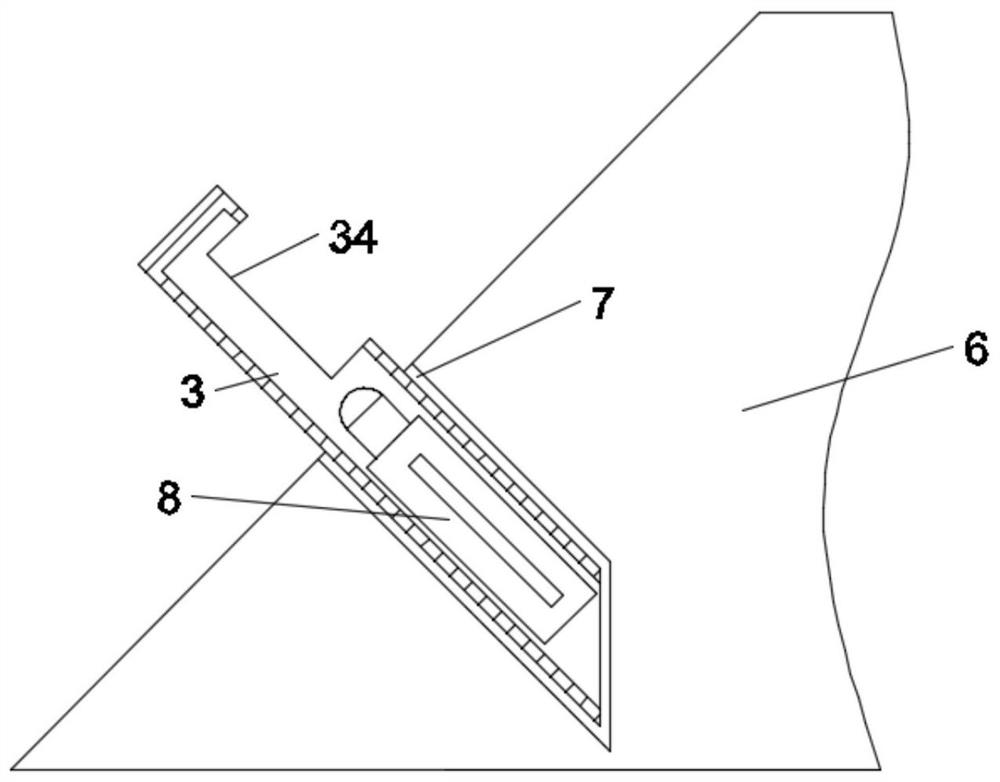

[0026] In the embodiment of the present invention, step 1: the entire device is arranged perpendicular to the slope of the embankment 6, and the triangle support frame 4 is adjusted so as to be stable; Go deep into the slope of the embankment 6 to form oblique deep holes 7; Step 3: step on the foot-operated pull-out device 5, so that the casing 3 is pulled out together with the soil in the pipe, and the ...

Embodiment 2

[0028] Such as Figure 1-Figure 7 As shown, in the embodiment of the present invention, the percussion device 2 includes a housing 21, the upper end of the left side of the housing 21 is fixed with a sliding seat 22 for the vertical support rod 1 to slide, and the left side of the housing 21 The lower end is fixed with a hand-held pressing plate 23, and the inside of the casing 21 is provided with a casing channel 24 for the casing 3 to enter. The casing 21 is provided with an installation space 25, and a knocking mechanism is installed in the installation space 25. Subject 26.

[0029] In the embodiment of the present invention, when the main body 26 of the knocking mechanism moves, the palm presses the hand-held pressing plate 23 , so that the housing 21 moves downward stably, and the housing 21 slides on the vertical support rod 1 .

Embodiment 3

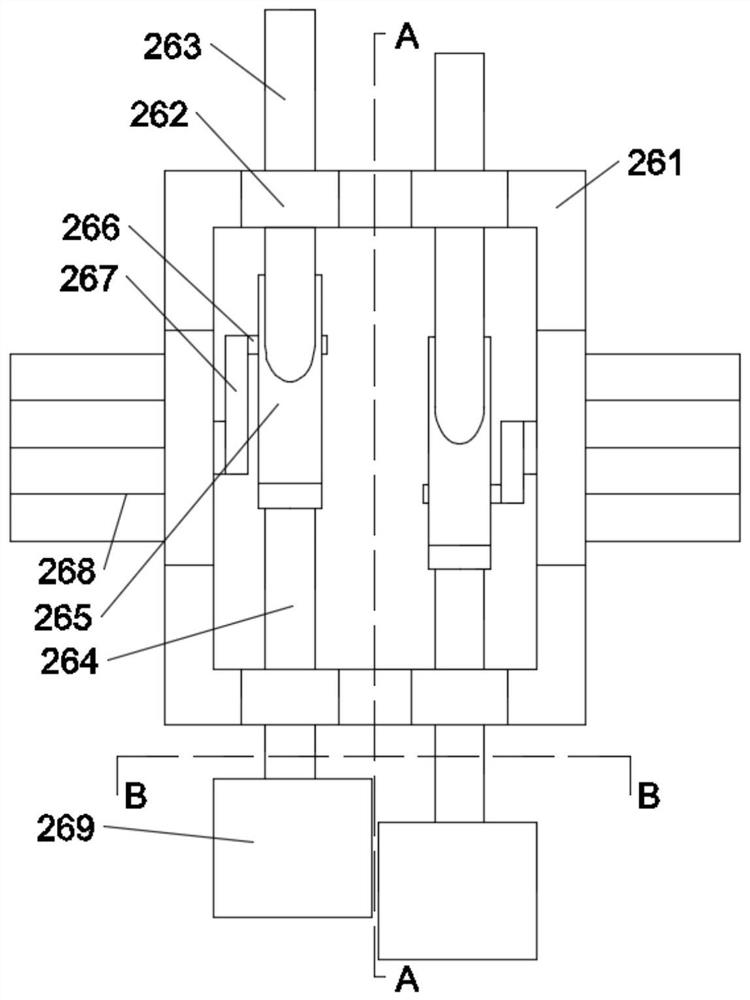

[0031] Such as Figure 1-Figure 7 As shown, in the embodiment of the present invention, the main body 26 of the knocking mechanism includes a back-shaped bottom plate 261, and the back-shaped bottom plate 261 is provided with shaft seats 262 symmetrically up and down, left and right, and the upper and lower two shaft seats 262 are respectively slidably connected. There is an upper sliding shaft 263 and a lower sliding shaft 264, and an oblique connection between the upper sliding shaft 263 and the lower sliding shaft 264 has a return-shaped sloping plate 265 with a rectangular through groove in the middle, and the inner sliding connection of the return-shaped sloping plate 265 There is a cylindrical rod 266 fixedly connected to a rotating plate 267 connected to a motor 268 .

[0032] In the embodiment of the present invention, the principle of movement of the main body 26 of the knocking mechanism: the left and right two motors 268 rotate to drive the rotating plate 267, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com