Paper conveying system used for packaging printing equipment

A technology for paper conveying and packaging printing, which is applied in the directions of transportation and packaging, thin material processing, winding strips, etc. It can solve the problems of low paper printing processing efficiency and inability to guide and convey paper, so as to prevent wrinkling and run stably , good continuity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

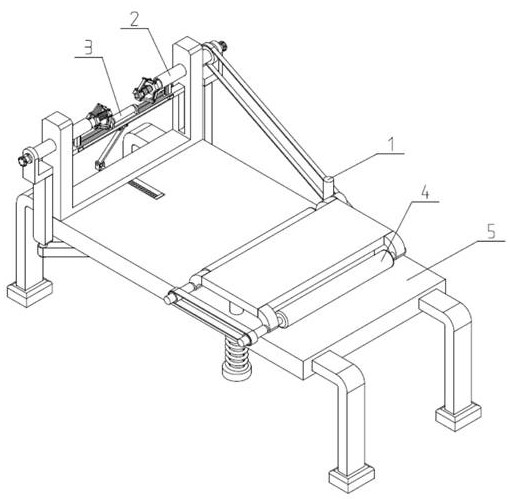

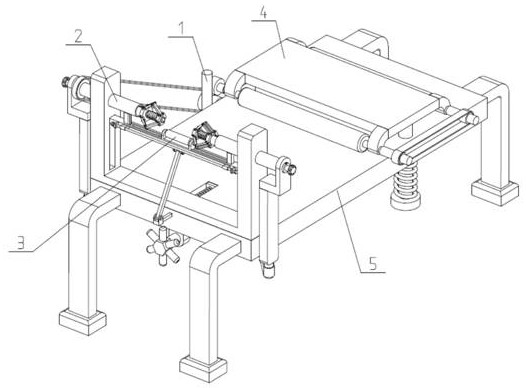

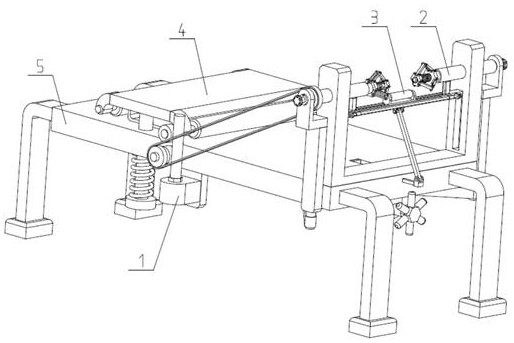

[0037] Such as Figure 1-12 As shown, the paper conveying system for packaging and printing equipment includes a driving mechanism 1, a paper guiding mechanism 2, a tension limit mechanism 3, a paper conveying mechanism 4 and a frame 5. The driving mechanism 1, the paper guiding mechanism 2 and the paper conveying mechanism 4 are all connected to the frame 5; the driving mechanism 1 is connected to the paper guiding mechanism 2 and the paper conveying mechanism 4; the paper guiding mechanism 2 and the The paper conveying mechanism 4 is arranged oppositely; the lower end of the tension limiting mechanism 3 is connected to the frame 5 , and the upper end of the tension limiting mechanism 3 is connected to the inner side of the paper guiding mechanism 2 . The paper delivery system for packaging and printing equipment of the present invention, when in use, installs the roll paper roll wrapped with the paper roll on the paper guide mechanism 2, and presses against the roll paper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com