All-solid-waste pavement concrete utilizing steel slag in large proportion and preparation method thereof

A large-scale, concrete technology, which is used in the comprehensive utilization of solid waste resources and building materials, can solve problems such as stability problems that have not been effectively solved, reduce energy consumption and processing difficulties, improve utilization, and reduce steel slag piles. status quo effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

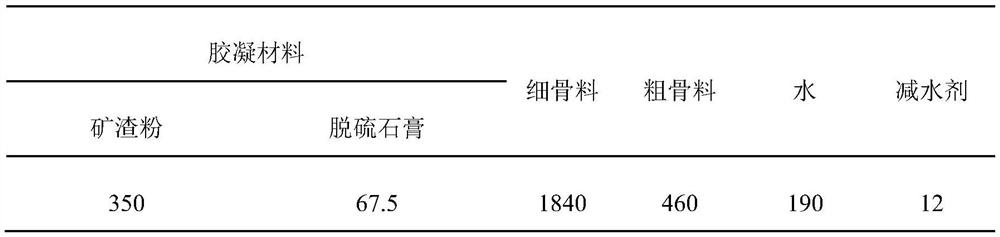

Embodiment 1

[0037] A kind of all-solid waste pavement concrete using steel slag in a large proportion, its cementitious material is prepared from the following raw materials in mass percentage: slag powder 83.8%, desulfurized gypsum 16.2%, slag powder specific surface area 560m 2 / kg, desulfurized gypsum is ground to a specific surface area of 400m 2 / kg. In concrete, cementitious material accounts for 14.3%, aggregate accounts for 78.78%, water accounts for 6.51%, and water reducing agent accounts for 0.41%. The coarse aggregate is 5mm-25mm converter steel slag, and the fine aggregate is <5mm converter steel slag. The agent is a solid polycarboxylate superplasticizer.

[0038] The concrete mix ratio is shown in the following table: (amount of concrete material per cubic meter: kg / m 3 )

[0039]

[0040] According to the mixing ratio shown in the above table, put the raw materials into the concrete mixer and mix them evenly, and pour them into a mold of 100mm×100mm×100mm at a tempe...

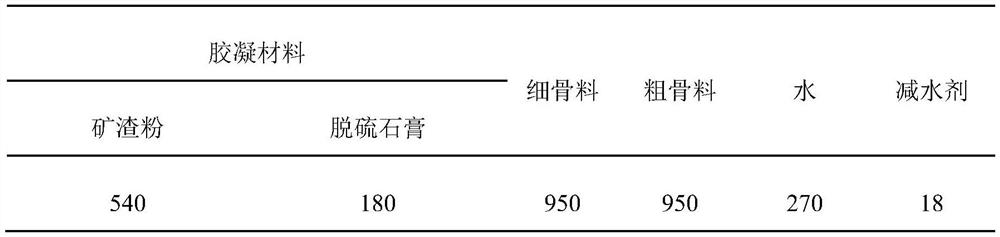

Embodiment 2

[0043] A kind of all-solid waste pavement concrete using steel slag in a large proportion, its cementitious material is prepared from the following raw materials in mass percentage: slag powder 75%, desulfurized gypsum 25%, slag powder specific surface area 560m 2 / kg, desulfurized gypsum is ground to a specific surface area of 400m 2 / kg. In concrete, cementitious material accounts for 24.76%, aggregate accounts for 65.34%, water accounts for 9.28%, and water reducing agent accounts for 0.62%. The coarse aggregate is 5mm-25mm converter steel slag, and the fine aggregate is <5mm converter steel slag. The agent is a solid polycarboxylate superplasticizer.

[0044] The concrete mix ratio is shown in the following table: (amount of concrete material per cubic meter: kg / m 3 )

[0045]

[0046] According to the mixing ratio shown in the above table, put the raw materials into the concrete mixer and mix them evenly, and pour them into a mold of 100mm×100mm×100mm at a tempera...

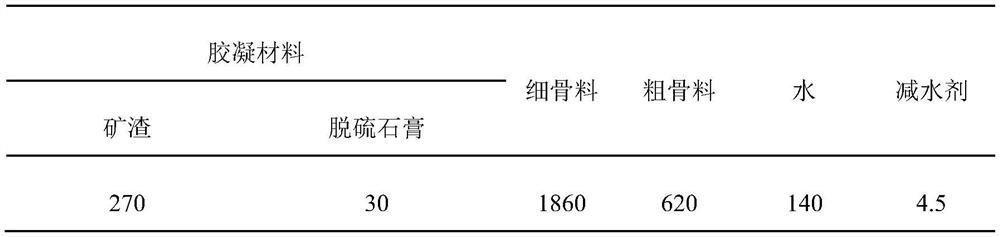

Embodiment 3

[0049] A kind of all-solid waste pavement concrete using steel slag in a large proportion, its cementitious material is prepared from the following raw materials in mass percentage: slag powder 90%, desulfurized gypsum 10%, slag powder specific surface area 560m 2 / kg, desulfurized gypsum is ground to a specific surface area of 400m 2 / kg. In concrete, cementitious material accounts for 10.26%, aggregate accounts for 84.8%, water accounts for 4.79%, and water reducing agent accounts for 0.15%. The coarse aggregate is 5mm-25mm converter steel slag, and the fine aggregate is <5mm converter steel slag. The agent is a solid polycarboxylate superplasticizer.

[0050] The concrete mix ratio is shown in the following table: (amount of concrete material per cubic meter: kg / m 3 )

[0051]

[0052] According to the mixing ratio shown in the above table, put the raw materials into the concrete mixer and mix them evenly, and pour them into a mold of 100mm×100mm×100mm at a temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com