A device and method for adjusting the balance of anode groups in a continuous anode electrolyzer

A technology of anode electrolysis and anode group, which is applied in the field of aluminum electrolysis, can solve problems such as the inclination of the anode group and cannot be leveled, and achieve the effects of stable tank conditions, stable and reliable operating conditions, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

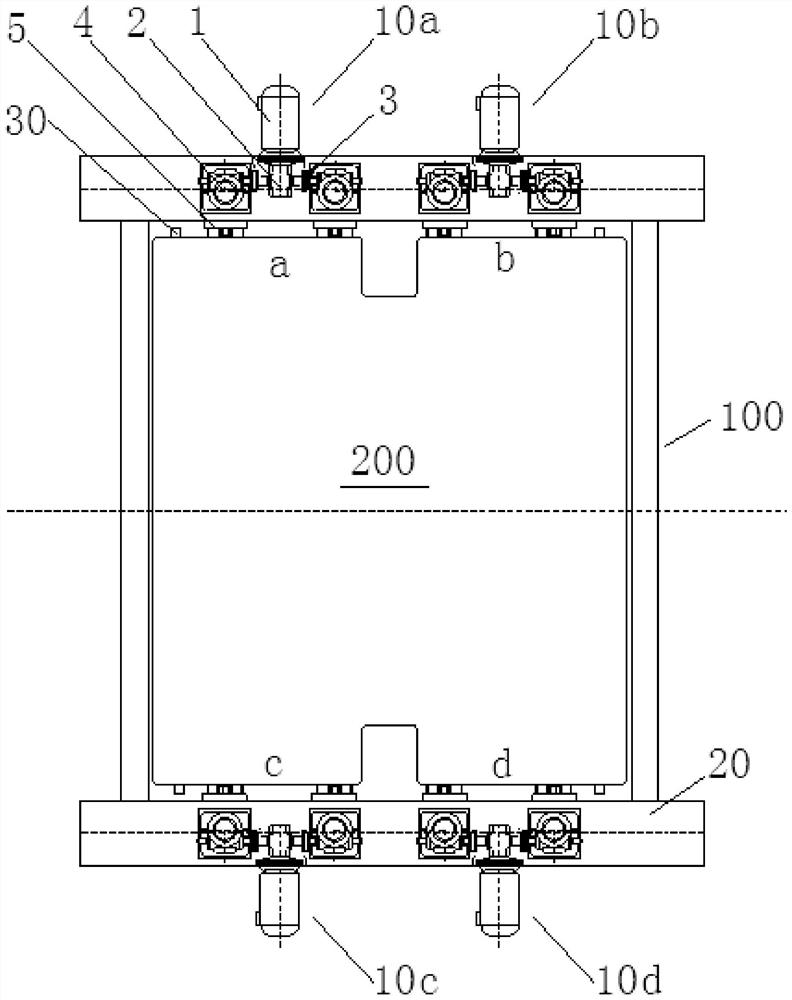

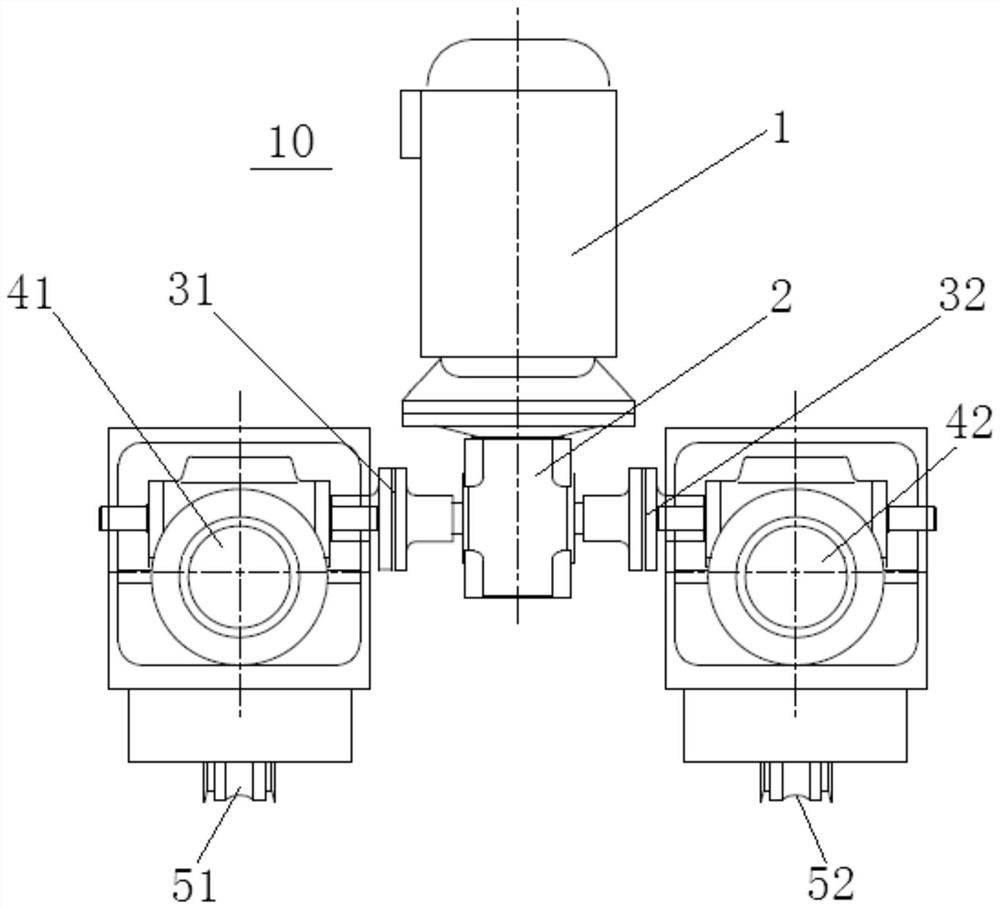

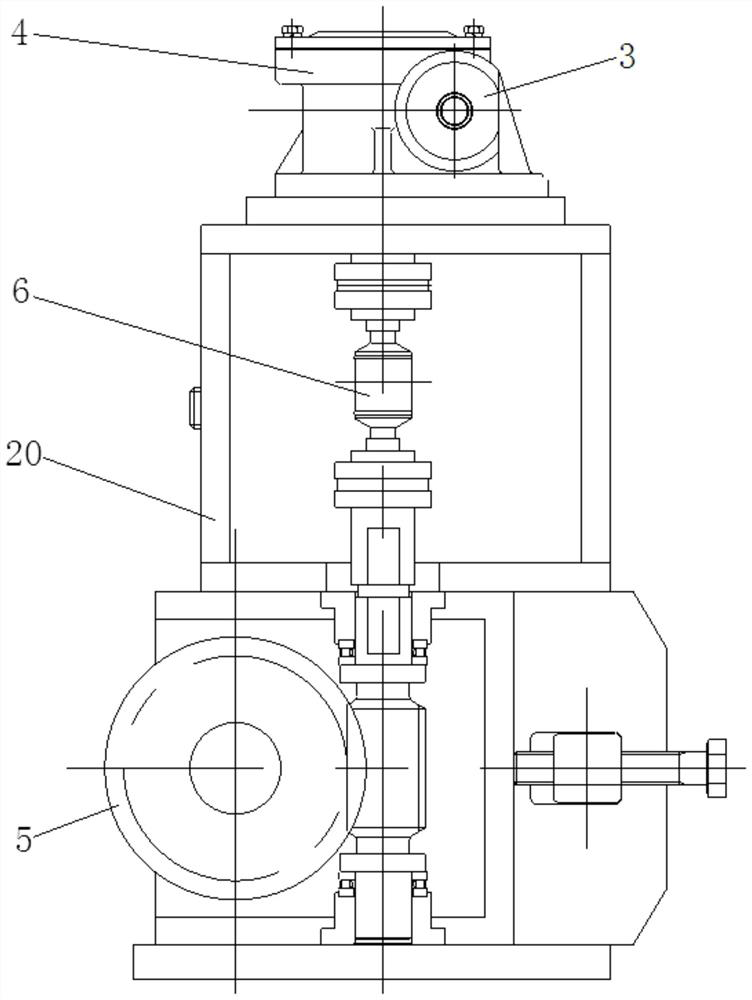

[0038] An embodiment of the present invention provides a device 100 for adjusting the balance of anode groups in a continuous anode electrolytic cell, which includes more than two anode group balance adjustment units 10, and more than two anode group balance adjustment units 10 are respectively located in the anode groups of the continuous anode electrolytic cell Two opposite sides of 200, such as figure 1 shown. The structure of each anode group balance adjustment unit 10 is exactly the same, and the specific number of anode group balance adjustment units 10 depends on the load of the anode group 200 (i.e. the weight of the anode group). At least four anode group balance adjustment units 10 should be provided for the anode group 200. For an anode group 200 with a small load (including only a single anode), two anode group balance adjustment units 10 can meet the balance adjustment requirements. The specific number of anode group balance adjustment units 10 is not limited in ...

Embodiment 2

[0051] Based on the same inventive concept, this embodiment provides a method for adjusting the balance of the anode group, which is implemented based on the device 100 for adjusting the balance of the anode group in the above-mentioned embodiment 1 for a continuous anode electrolyzer. see Figure 5 , the method includes the following steps:

[0052] During the operation of the continuous anode electrolyzer, detect the balance state of the anode group of the continuous anode electrolyzer, and judge whether the anode group has unilateral inclination or local unevenness;

[0053] When the anode group tilts on one side, the anode group balance adjustment unit 10 on the side that needs to be adjusted is controlled to operate, and the dial wheel 5 is driven to rotate through the power device 1, and the dial wheel 5 meshes with the anode group to drive the inclined side of the anode group to rise or fall, eliminating Tilt, so as to achieve the balance of the whole anode group;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com