Rotary knob assembly and washing machine using same

A washing machine and knob technology, applied in the field of washing machines, can solve problems such as unstable installation, poor rotation feel, and loud noise, and achieve the effects of reducing overall weight, easy operation and use, and light and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

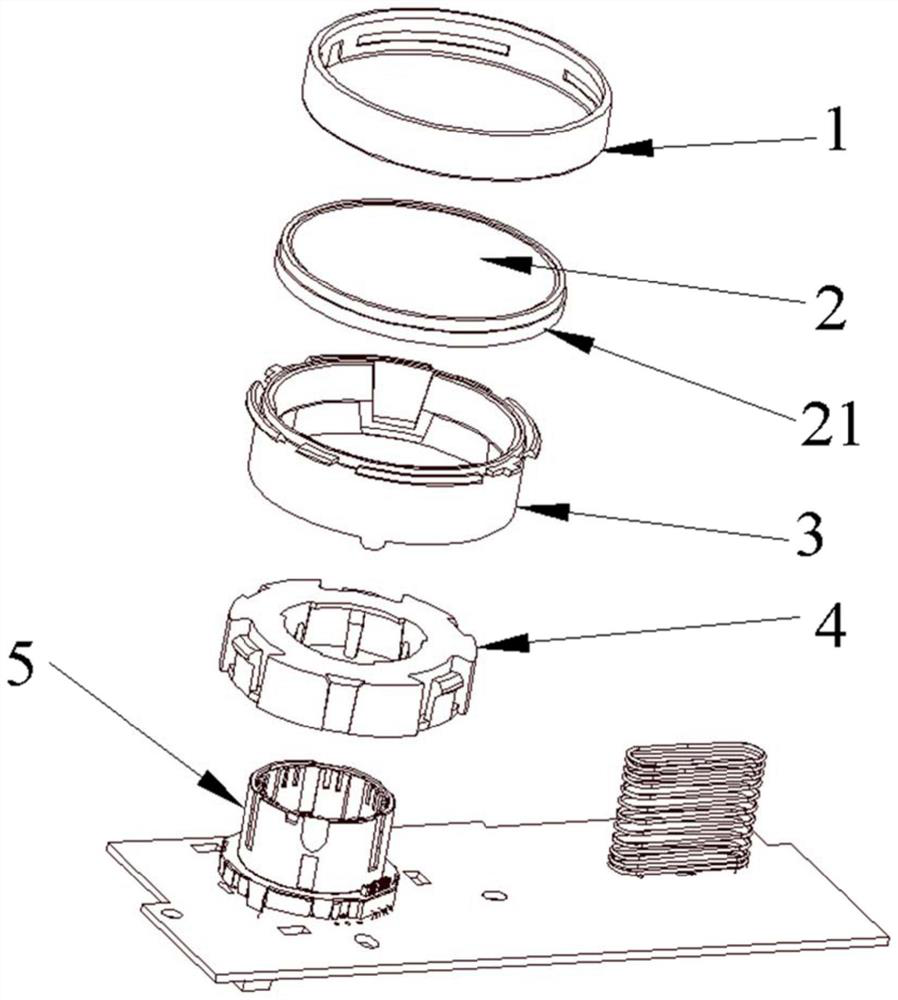

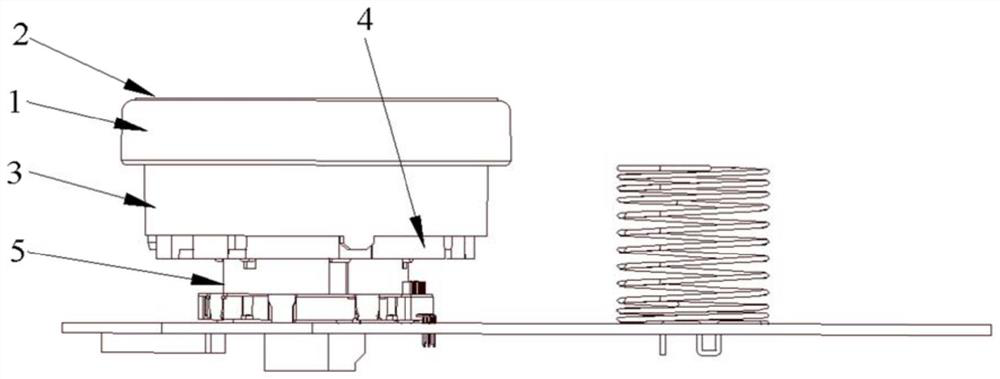

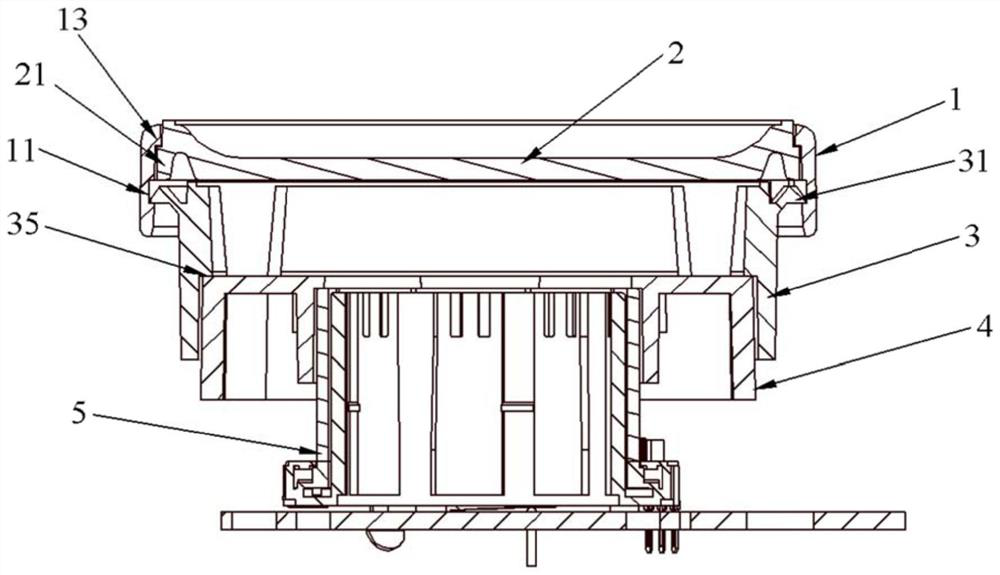

[0046] In this embodiment, a knob assembly is provided, which includes a knob body 3 arranged coaxially, a transmission member 4 and a shaftless encoder 5, and also includes a knob cover 2 and a ring for hooping the knob cover 2 on the top surface of the knob body 3. The knob ring 1, the knob ring 1, the knob body 3, the transmission member 4 and the shaftless encoder 5 are sequentially arranged layer by layer, so that the connection structure in the circumferential direction of the knob assembly is matched and hidden.

[0047] In this embodiment, the shaftless encoder is a standard part, installed on the control circuit board, and has a hollow inner and outer two-layer structure. The outer layer is a rotatable outer ring. The rotation of the outer ring can generate electrical signals and control the operation The mode is selected, and the inner layer is a fixed inner ring. In order to rotate the outer ring of the shaftless encoder, the present invention provides a hollow knob...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063] In this embodiment, the bottom of the second guide post 34 protrudes from the edge of the bottom surface of the knob body 3; since the guide and engagement structure is arranged on the periphery of the knob body, it is difficult to distinguish the installation position during assembly, so it is preferable to place the second guide post 34 The bottom protrudes from the edge of the bottom surface of the knob body, which is convenient for assemblers to align and install.

[0064] Other implementation modes of this embodiment are the same as embodiment 1.

Embodiment 3

[0066] The difference between this embodiment and embodiment 1 is:

[0067] In this embodiment, the top of the second guide column 34 is provided with a limiting card edge 35 extending along the inner circumference of the knob body 3; contact limit.

[0068] In this embodiment, the limiting card edge limits the position of the knob body in the axial direction of the knob assembly, and the installation structure is more compact and firm under the cooperation of the guide and the clamping structure.

[0069] Other implementation modes of this embodiment are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com