Angle-adjustable translational lifting machine

An adjustable and translational technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of unsafety, large power loss, cumbersome operation, etc., and achieve stable loading and unloading of materials, fast boom lifting speed, Avoid the effect of moving the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

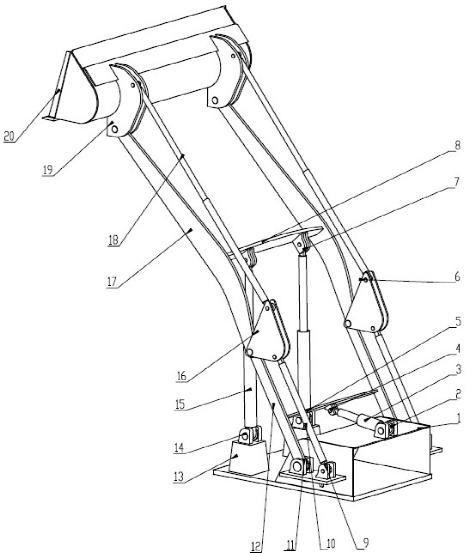

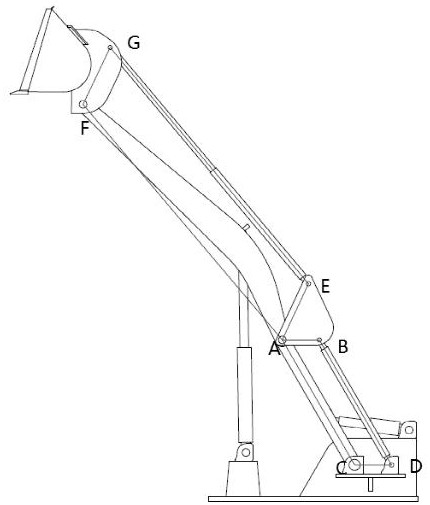

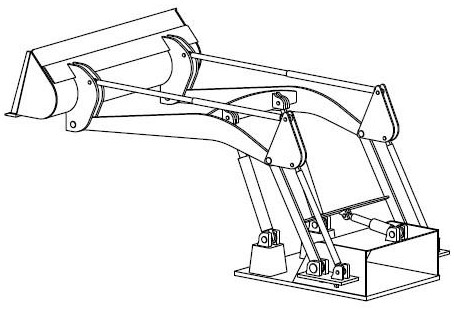

[0026] combine Figure 1 to Figure 5 As shown, an angle-adjustable translational lifting machine is installed on the front frame 1 and distributed symmetrically along the center of the front frame 1 . A pair of support seats 13, a pair of ear seats I11, and a pair of ear seats II9 are welded and fixed sequentially from front to back on the front frame 1, and ear seats IV14 are welded and fixed on the support seat 13. There is a boss in the middle of the front frame 1, and the lug seat III2 is fixed on the boss.

[0027] Angle-adjustable translational lifting machinery mainly includes parallelogram hinge mechanism I and parallelogram hinge mechanism II;

[0028] Parallelogram hinge mechanism Ⅰ:

[0029] The lower end of the boom I12 is hinged on the point C of the lug I11, and the upper end of the boom I12 is hinged on the point A of the triangular hinge plate 16. The lower end of the connecting rod 10 is hinged on the point D of the lug II 9 , and the upper end of the conne...

Embodiment 2

[0042] The rear vehicle frame is hinged with the front vehicle frame 1, and the connection between the front vehicle frame 1 and the rear vehicle frame adopts a composite hinged structure. The composite hinge structure adopts the composite hinge structure described in the Chinese patent (CN110356470A), which realizes the left and right rotation and up and down swing of the front and rear frames, reduces the turning radius of the construction machinery, allows the machinery to be used in narrow working conditions, and improves the mechanical performance. Site adaptability.

Embodiment 3

[0044] The upper ends of the boom II 17 and the tipping bucket oil cylinder 18 have a quick-change attachment connection mechanism, and the implement 20 is installed on the quick-change attachment connection mechanism. The quick-change attachment connection mechanism adopts the quick-change connection frame described in the Chinese patent (CN205557624U). The two hinge points on the connection frame replace the two hinge points F and G to form a parallelogram structure. After completion, the machine can replace buckets, forks and other tools to complete different operations, which increases the functionality of the machine and improves the versatility and site adaptability of the construction machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com