Isolating switch operating mechanism with modularly designed control loop and using method

A modular design and isolating switch technology, applied in the direction of air switch components, etc., can solve the problems of relays and secondary components and contacts, low work efficiency, high failure rate of equipment operation, etc., to reduce contact with live secondary lines risks, reduce equipment utilization, and optimize operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

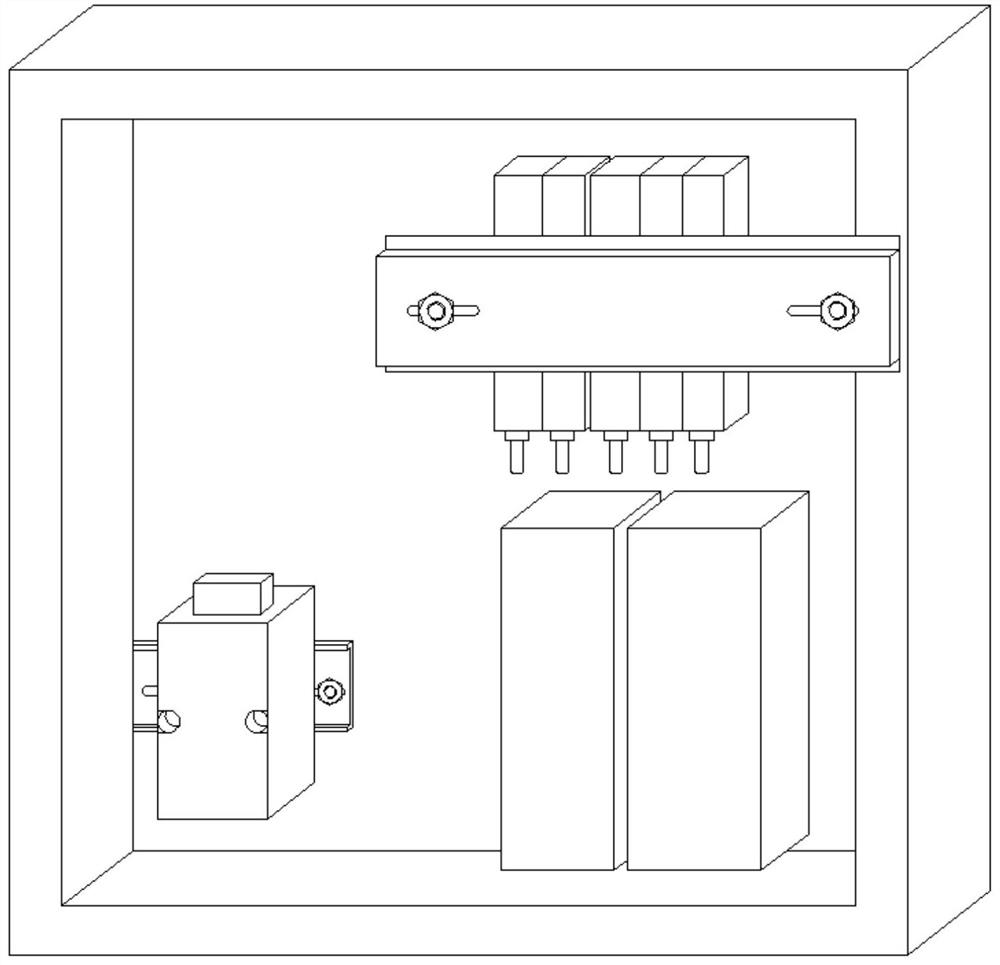

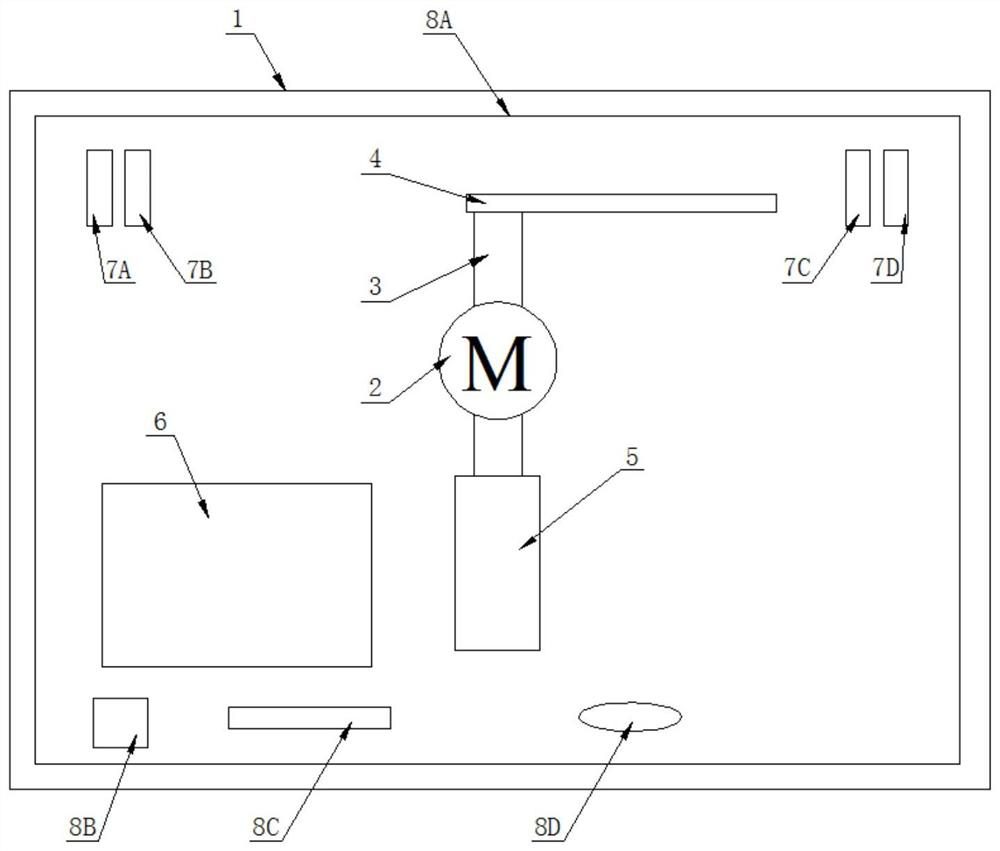

[0046] refer to figure 1 , the present embodiment provides an isolating switch operating mechanism with a modular control circuit design; it includes an isolating switch operating mechanism with a modular control circuit design, which includes a box 1 with a cover; inside the box 1 The motor 2 and the output end of the motor 2 are respectively connected to the input end of the action unit 4 and the auxiliary switch assembly 5 through the transmission device 3; the motor 2 is connected to the control unit 6 through a wire, and is controlled by the control unit 6; the control unit 6 respectively electrically connected with the auxiliary switch assembly 5, the opening and closing assembly 7 and the temperature control assembly 8;

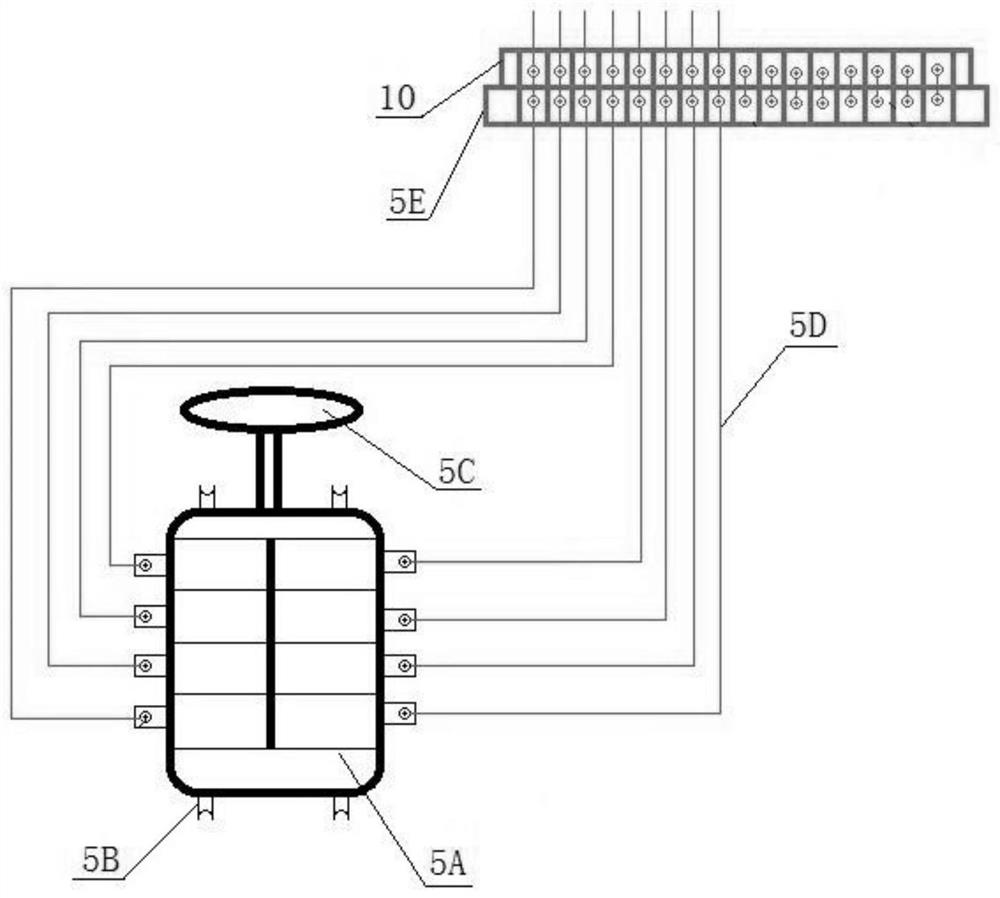

[0047] The auxiliary switch assembly 5 includes an auxiliary switch body 5A; the auxiliary switch body 5A is provided with a fixing seat 5B and a connecting flange 5C for detachable installation with the box body 1; the auxiliary switch body 5A is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com