Food boxing device

A food and control device technology, which is applied in food packaging, packaging, packaging protection, etc., can solve problems such as deviation from the loading position, damage to commodity value, and reduced food storage efficiency, achieving the effect of achieving storage efficiency and improving storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

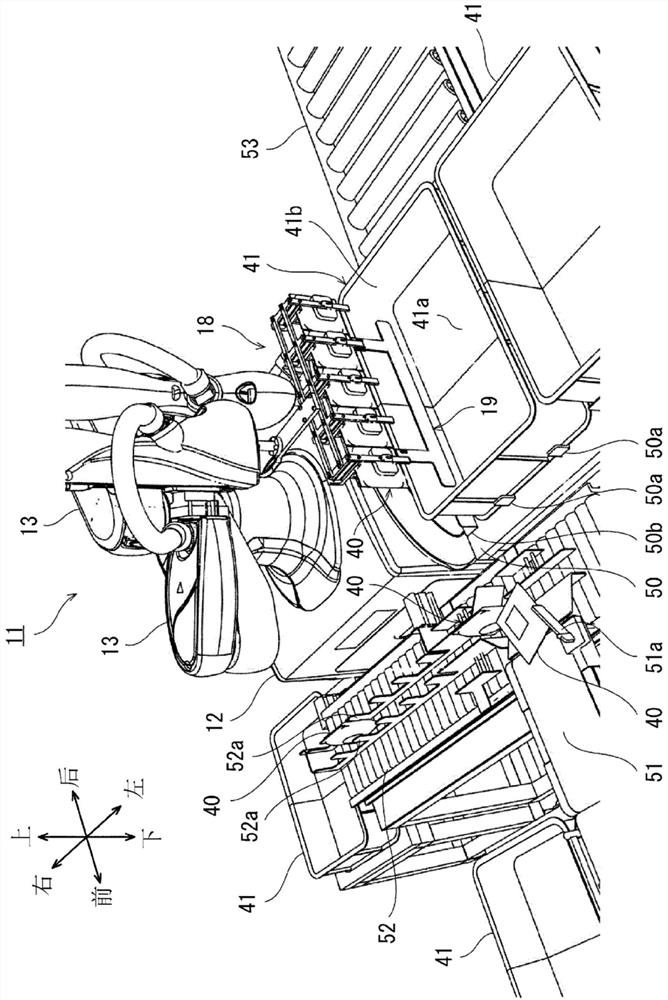

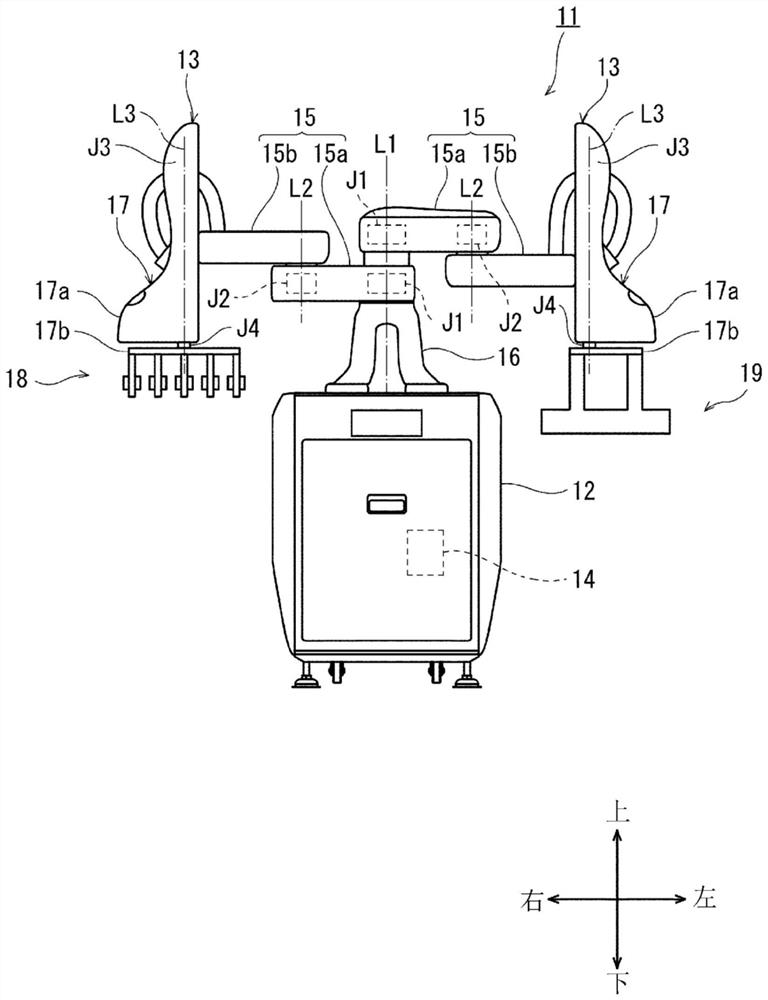

[0048] figure 1 It is a top view schematically showing the overall structure of the food packaging device according to the first embodiment of the present invention. The food packing device of the present embodiment is introduced into, for example, a food production site. Such as figure 1 As shown, the packaging apparatus for foods is constituted by a robot 11 including a pair of robot arms (hereinafter, sometimes simply referred to as “arms”) 13 , 13 . Hereinafter, the direction in which the pair of arms are opened is referred to as the left-right direction. The direction parallel to the axis center of the base axis is referred to as an up-down direction. The direction perpendicular to the left-right direction and the up-down direction is referred to as the front-rear direction.

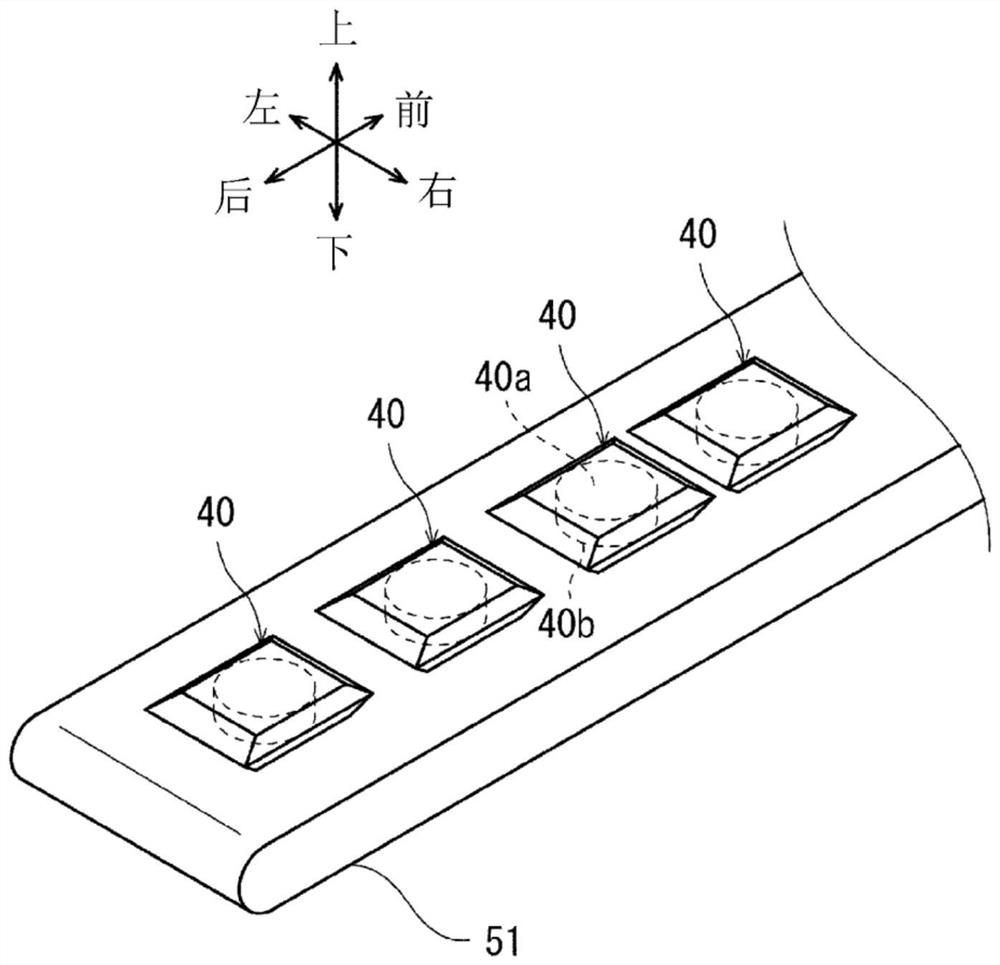

[0049] A first conveyor 51 and a second conveyor 52 are arranged in front of the robot 11 . The first conveyor 51 is a device for transferring the food 40 to the start of the second conveyor 52...

no. 2 approach

[0076] Hereinafter, a second embodiment will be described. The basic structure of the holding device 10 of the foodstuff 40 of this embodiment is the same as that of 1st Embodiment. In the following, the description of the configuration common to the first embodiment will be omitted, and only the different configuration will be described.

[0077] Figure 10 It is a figure which shows the packing apparatus of the food concerning 2nd Embodiment of this invention. Figure 11 yes means Figure 10 A diagram of the structure of the end effector 18A of the right arm 13. Such as Figure 11 As shown, the end effector 18A of this embodiment is the same as that of the first embodiment ( Figure 4 ) for comparison, the difference is that the lengths of the pair of holding members 22 in the longitudinal direction (herein the up-down direction) are the same (refer to Figure 11 (B)), but the other structures are the same, so detailed description is omitted.

[0078] Figure 12 yes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com