Novel long-range fire fighting monitor

A fire-fighting water cannon and long-range technology, which is applied in fire rescue and other directions, can solve the problems of small axial speed, easy topple over, large energy loss, etc., and achieve a smooth exit flow state, easy loading and transportation, and small loss in the pipe Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

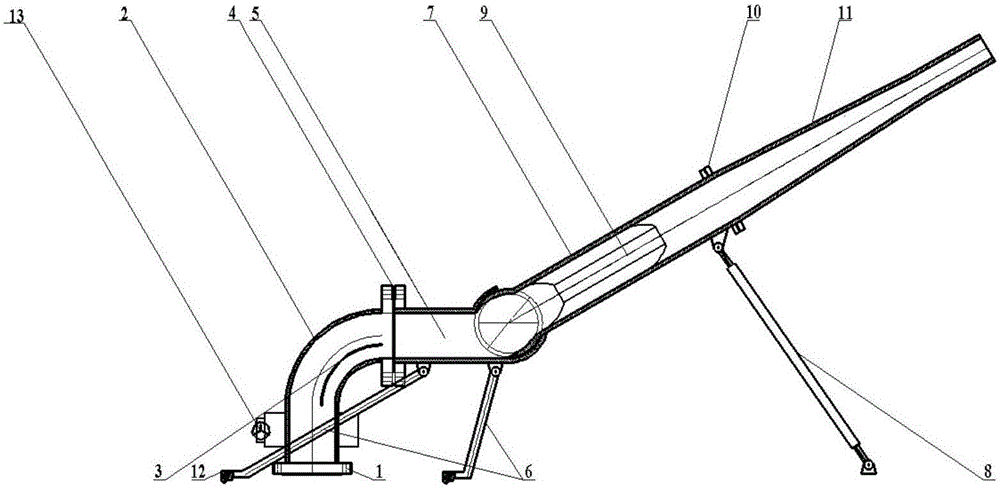

[0031] now attached Figure 1-8 Further description of the technical solution of the present invention:

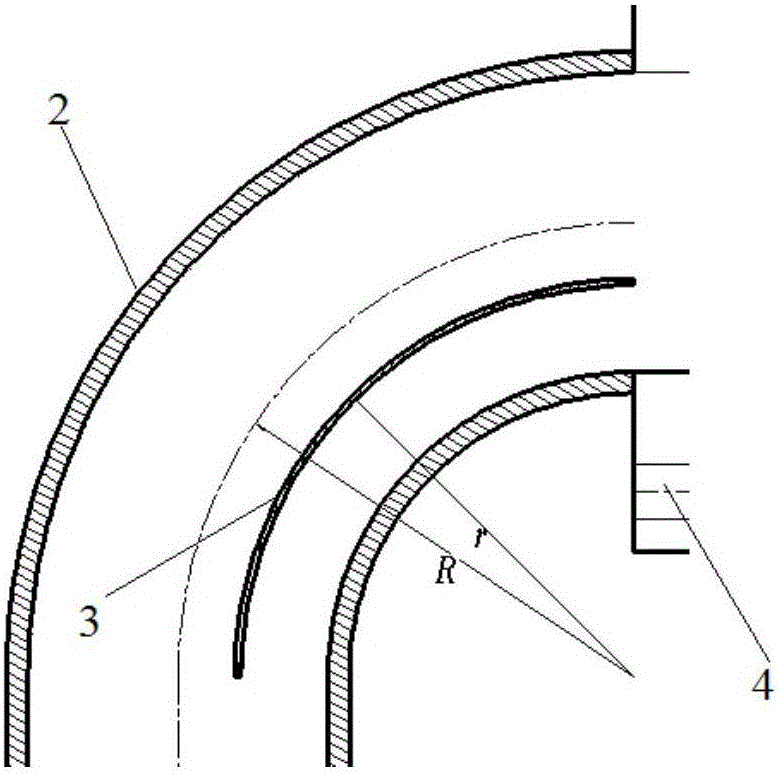

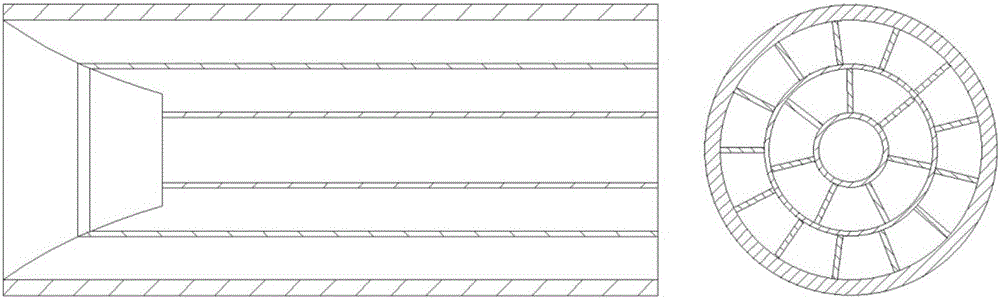

[0032] combined with figure 1 , the water inlet pipe 2 is a 90° arc, and includes two straight pipe sections and an arc section, and a worm gear mechanism is arranged on the outside of the vertical straight pipe section. The lower side of the pipe section is provided with a flange A1 for combining with other pipes. The arc section is a 90° arc, and a guide vane 3 is provided at the 90° arc. The guide vane 3 is concentric with the 90° arc. The radius of curvature of the axis of the elbow is 170 mm, and the welding position of the deflector 3 is located in the half channel near the center of the elbow, and the distance from the axis is 20 mm. The pipelines of the dynamic joint pipe 7 and the static joint pipe 5 adopt circular straight pipes except for the spherical surface; There is a gap between them, and the gap is sealed by bearing pressure plate and rubber; the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com