Engine and propeller system working platform and using method

A work platform and propeller technology, applied in workbenches, manufacturing tools, buildings, etc., can solve the problems of different maintenance locations, ineffective use, and high labor intensity, so as to improve flexibility, enhance adaptability, and ensure stair climbing. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

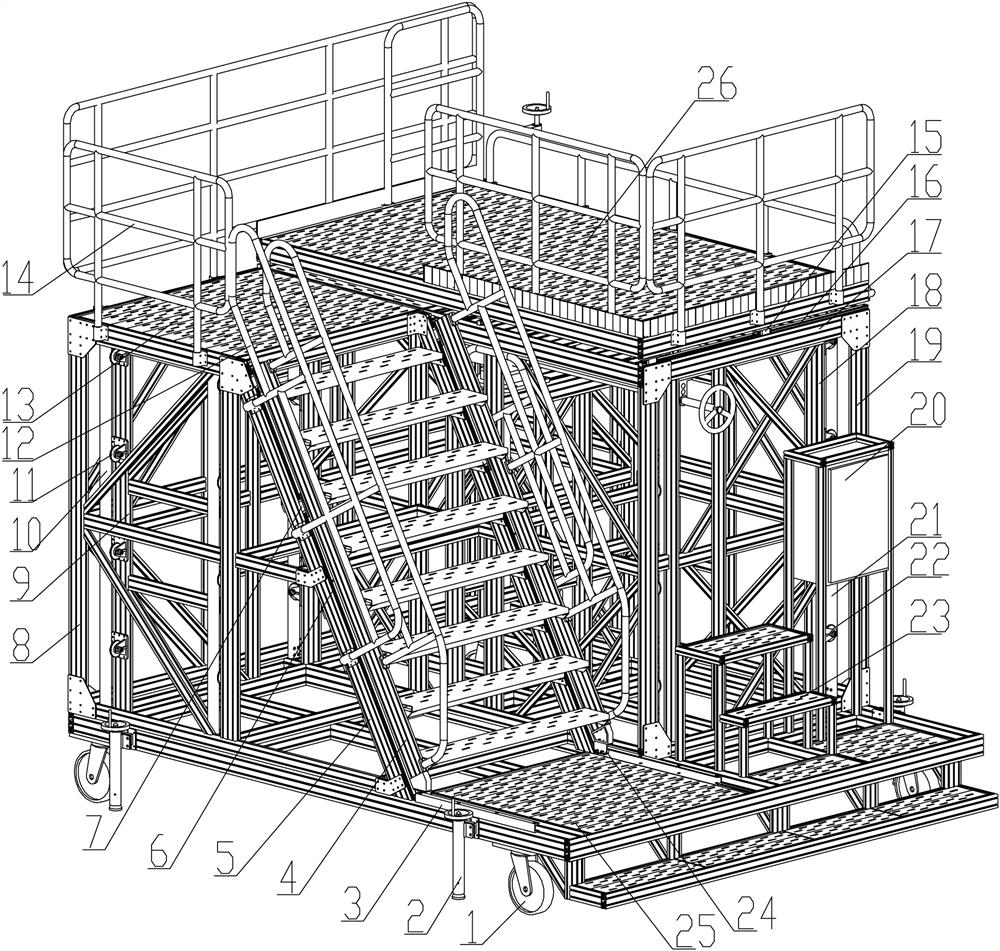

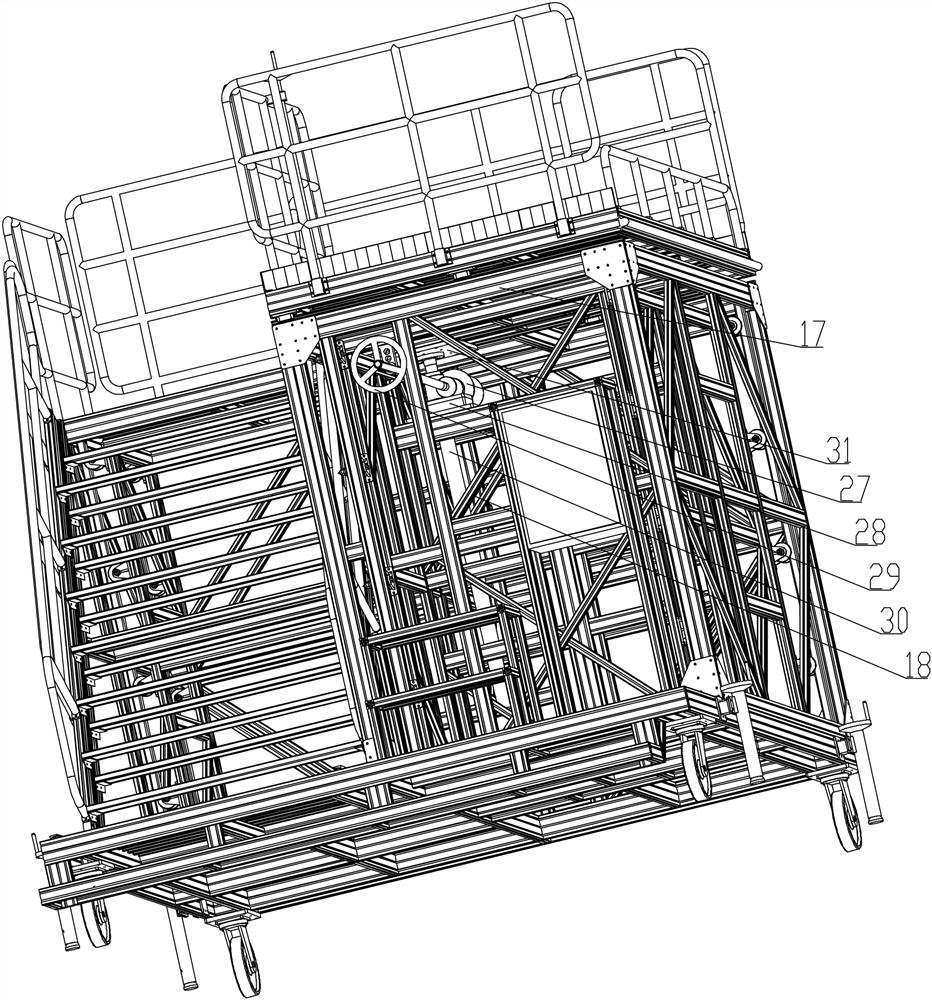

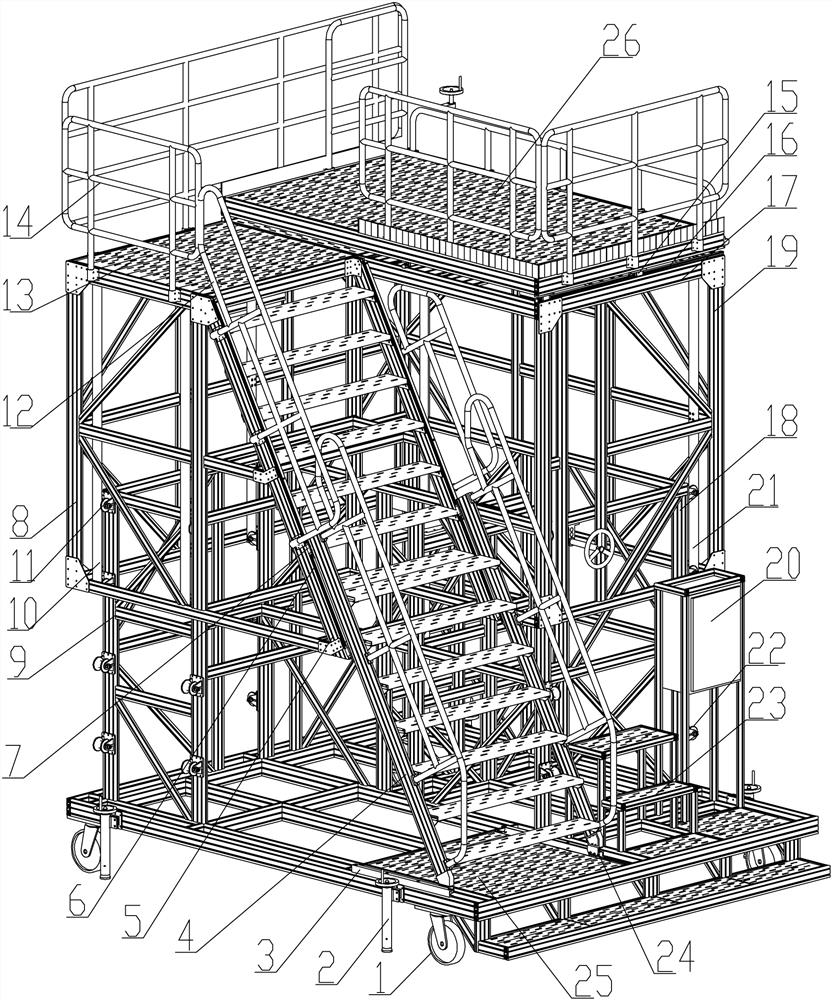

[0039] see Figure 1-6 , engine and propeller system working platform, it comprises bottom support platform 25, and the top of described bottom support platform 25 is fixed with first inner support frame 9 and second inner support frame 18, and the outside of described first inner support frame 9 passes through The first outer lifting frame 8 is slidably sleeved on the first guide wheel structure, and the second outer lifting frame 19 is slidably sleeved on the outside of the second inner support frame 18 through the second guide wheel structure. The top is fixed with a first top platform 13, and the top of the second outer lifting frame 19 is fixed with a second top platform 17, and is fixedly connected between the first top platform 13 and the second top platform 17; The side of the platform 13 is fixed with an upper ladder 5, and a follow-up ladder 4 is installed between the upper ladder 5 and the bottom support platform 25 through a sliding structure; A lifting mechanism ...

Embodiment 2

[0051] The using method of engine and propeller system working platform, it comprises the following steps:

[0052] Step 1: With the support of the supporting casters 1, push the entire working platform to move to the location of the aircraft engine and propeller that need to be overhauled;

[0053] Step 2: After initially adjusting the position of the working platform, stretch out the lifting support rod 2, and then fix and support the entire working platform to ensure its stability;

[0054] Step 3: According to the height of the engine, when the height of the platform needs to be adjusted, control the motor 27 of the lifting mechanism, drive the screw lifter 30 through the motor 27, and then drive the second outer lift frame 19 and the first outer lift frame through the screw lifter 30 8. Rise along the corresponding guide wheel structure along the second inner support frame 18 and the first inner support frame 9, and then realize the raising of the first top platform 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com