Gluing device for carton production line and working method thereof

A production line and viscose technology, which is applied in biological packaging, packaging, papermaking, etc., can solve the problems that viscose cartons are not easy to separate and the viscose effect is not good, and achieve the effect of improving the separation effect and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

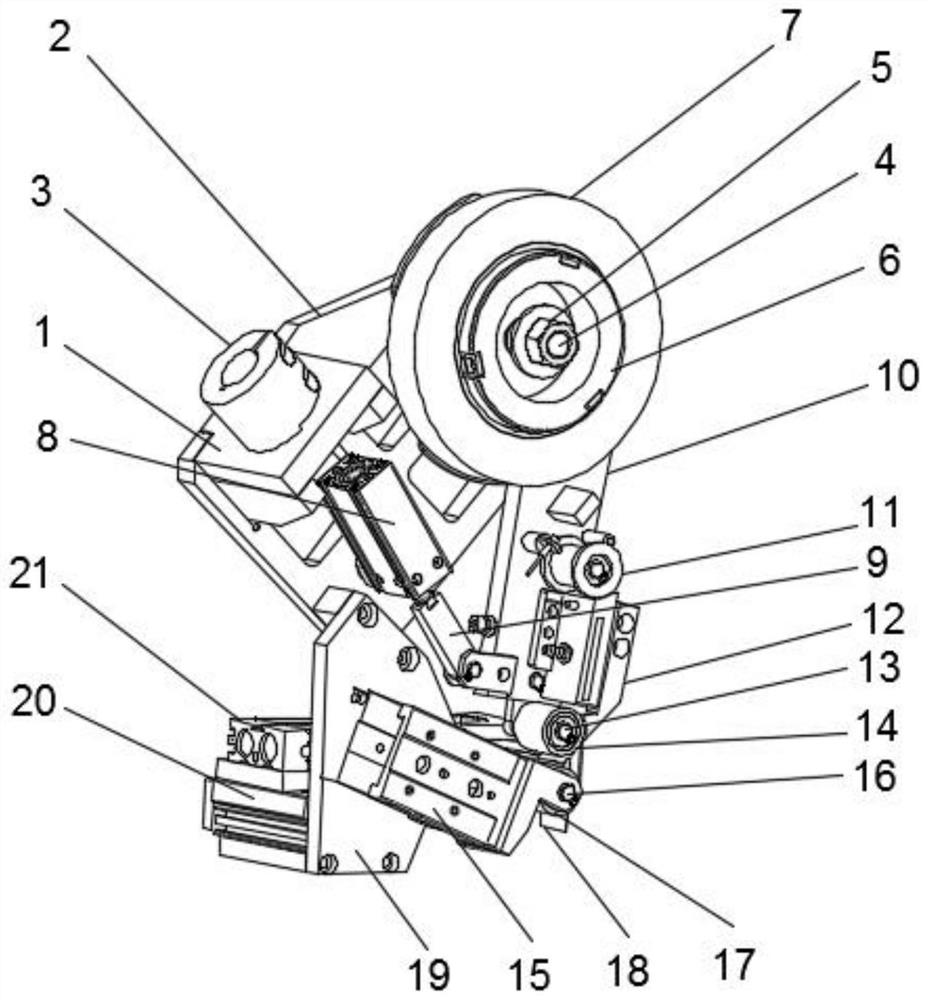

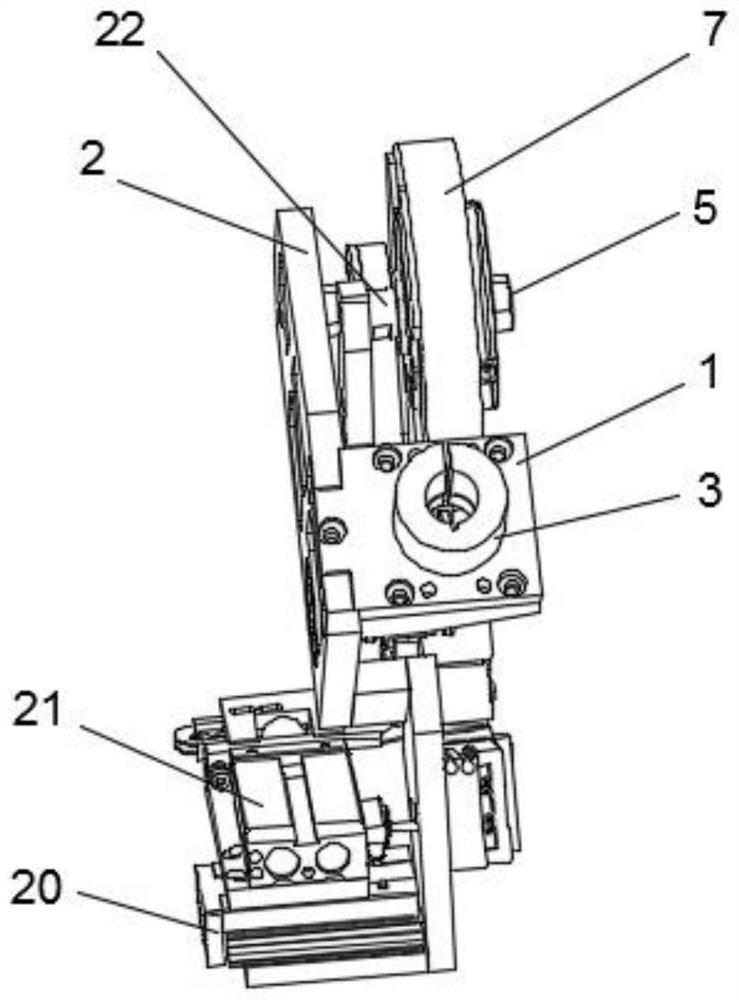

[0038] One side of the support base 1 is fixedly installed with a second connecting arm 8 and a fixed arm 19, and the second connecting arm 8 is located at

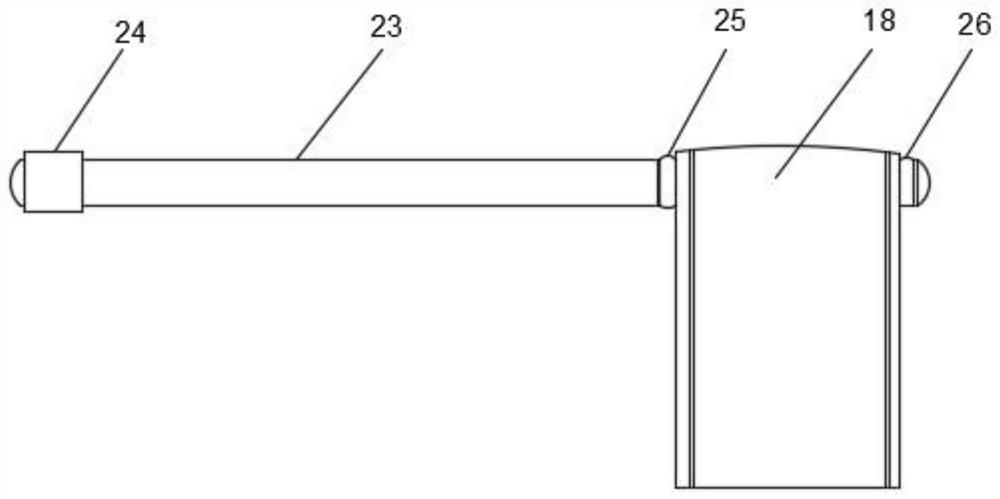

[0039] The position of the outer surface of the second rotating column 23 close to one side is to install the limiting plate 18, the first limiting ring 25 and the second limiting plate 18.

[0041] The upper end of the sliding plate 27 is provided with a limiting slot 38 at a position close to the front, and the vertical plate 28 runs through the limiting slot 38 and

[0042] The interior of the limiting plate 18 is fixedly installed with a first drive block 33 at a position close to the rear end, and the first drive block

[0044] The limiting plate 18 is rotatably connected with the second rotating column 23, and the interior of the first driving block 33 is provided with two groups of miniature

[0053] The limiting plate 18, the vertical plate 28, the sticking plate 39, the cutting knife 42 and the first driving block 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com