Synthesis and Application of Pseudochitosan and Its Derivatives

A pseudo-chitosan and polymer technology, which is used in the synthesis and application of pseudo-chitosan and its derivatives, can solve the problems affecting the range and effect of the product, low solid yield, long reaction time, etc., and achieve product Wide range of uses, low production costs, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

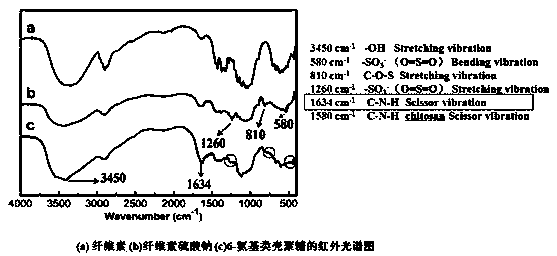

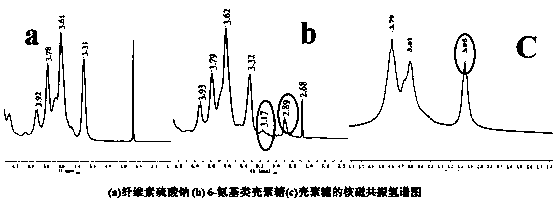

[0068] Cellulose sulfate was synthesized with microcrystalline cellulose as raw material and SO3 / DCE as sulfonating reagent. The concentration of SO3 is 1mnol / L, the ratio of moles of cellulose structural units to moles of SO3 is 3:8, the reaction time is 2h, and the reaction temperature is 25°C. After testing, the degree of sulfonation substitution of the prepared product was 0.96, which was used as a reaction intermediate for subsequent amination reaction.

Embodiment 2

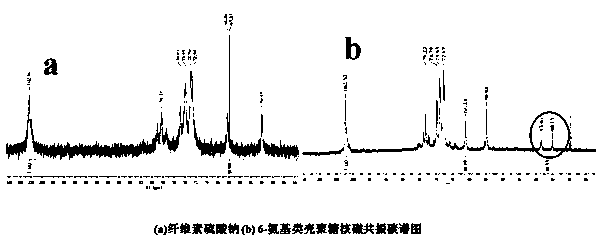

[0070] Sodium cellulose sulfate (NaCS) is dissolved in the ammoniacal liquor of 28% by mass fraction by the consumption in the table, is placed in autoclave, and analysis conditions such as different reaction time, reaction temperature, reaction pressure affect the effect of 6-aminocellulose The influence of degree of substitution and yield, determine the optimal process conditions, see Table 2, Table 3, and Table 4 for the results of related experiments and comparative experiments.

[0071] Table 2: Effects of different reaction temperatures on the degree of substitution and yield of 6-aminocellulose

[0072]

[0073] Note: *The calculation method of substitution degree is DS=(ωN / 14) / (ωC / 72) (the same below)

[0074] *Add excess 1mol / l NaOH solution to the obtained purified product, heat at 90-100°C to remove free ammonia in the system (the same below)

[0075] From the results in Table 2, it can be seen that the degree of substitution and the yield of the reaction increa...

Embodiment 3

[0084] Sodium cellulose sulfate (NaCS) and different kinds of amination reagents are dissolved in 30g deionized water according to the amount in the table, placed in a high-pressure reactor, and reacted according to the experimental conditions in Table 5 and Table 6. Related experiments and See Table 5 and Table 6 for the results of the control experiment.

[0085] Table 5: Effects of different amination reagents on the degree of substitution and yield of 6-aminocellulose

[0086]

[0087]

[0088] As can be seen from the results in Table 5, different amination reagents have different degrees of substitution in the reaction, and the substitution effect of ammonia water and ethylenediamine as the amination reagent is better.

[0089] Table 6: Effects of different ratios of amination reagents on the degree of substitution and yield of 6-aminocellulose

[0090]

[0091] It can be seen from the results in Table 6 that the degree of substitution and the yield of the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com