3D sorting logistics robot

A logistics robot and 3D technology, applied in the field of 3D picking logistics robots, can solve the problems of low efficiency, limited working efficiency and working height, and low shelf handling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further elaborated below in conjunction with embodiment.

[0031] In order to improve the deficiency of the technical level of the above-mentioned logistics equipment, the present invention provides a 3D operation logistics robot that takes into account the horizontal movement of the ground and the vertical climbing of the shelves. Input costs to meet the needs of densification, flexibility and intelligence.

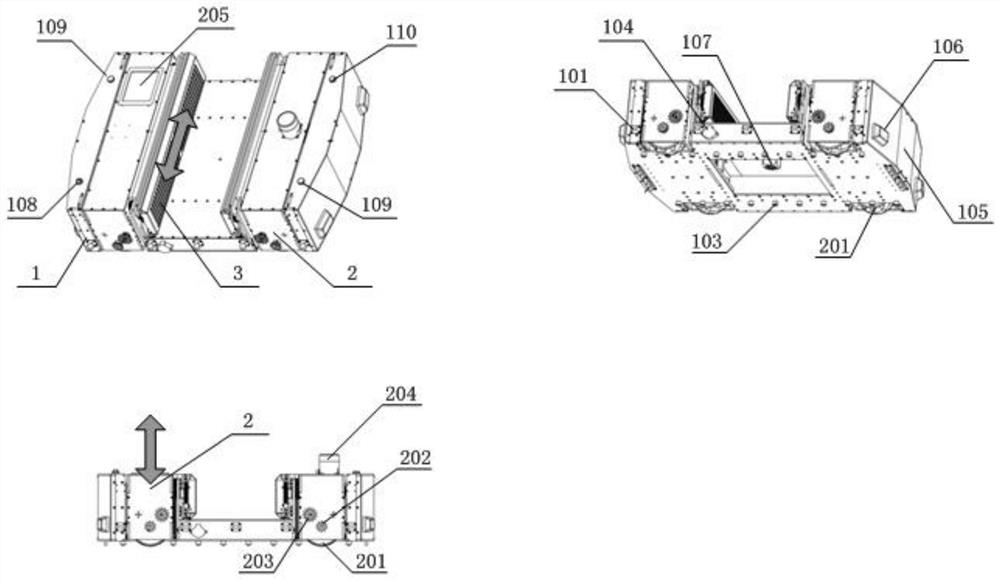

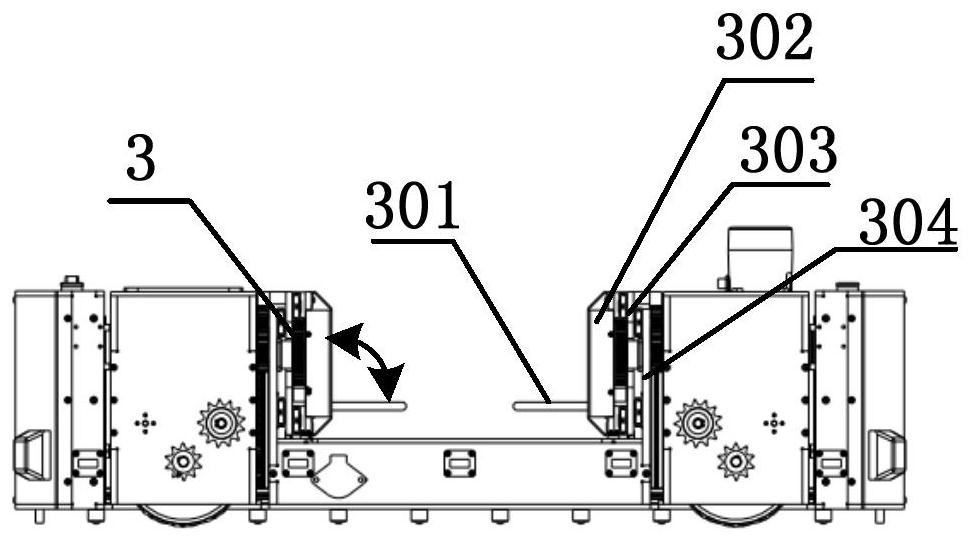

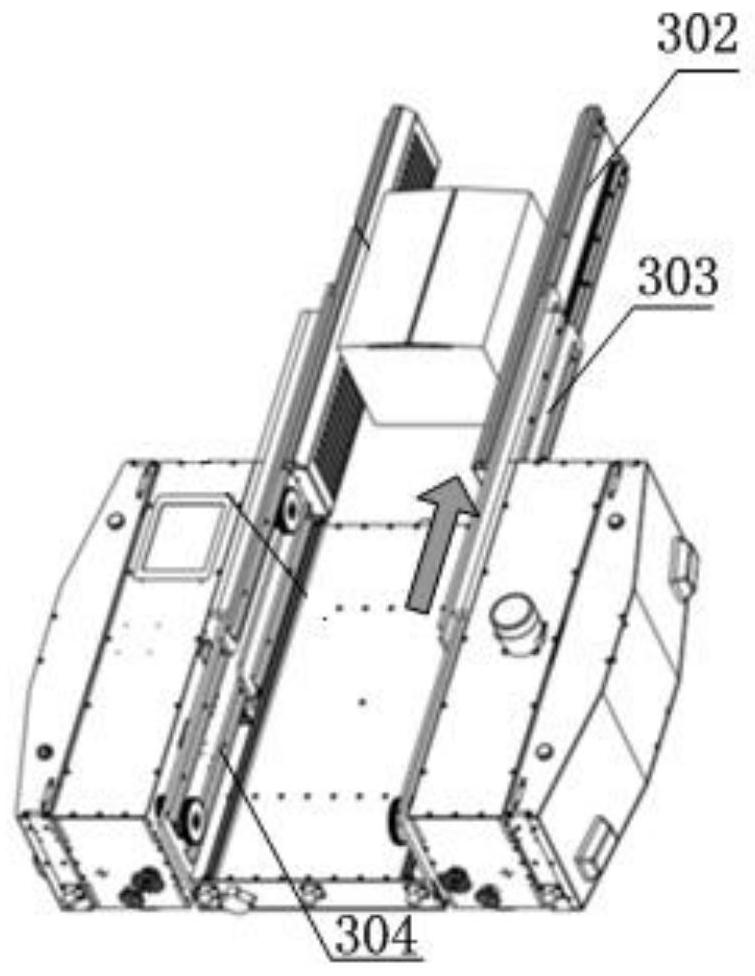

[0032] 3D operation logistics robot, such as figure 1As shown, it includes a load-bearing body 1, two vertical climbing power bodies 2, a fork 3 and a shelf 4; the two vertical climbing power bodies 2 are symmetrically arranged at the front and rear of the load-bearing body 1, and pass through the linear slide rail Connected with the body, it can move along the vertical direction of the carrying body 1 for the engagement and release of the climbing mechanism with the climbing body. The internal integrated compound motion components t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com