Automatic material taking and placing clamp for manipulator

An automatic pick-and-place, manipulator technology, applied in the direction of conveyor objects, transportation and packaging, can solve problems such as low efficiency and high cost, and achieve the effect of improving production efficiency, reducing manual operation, and high safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

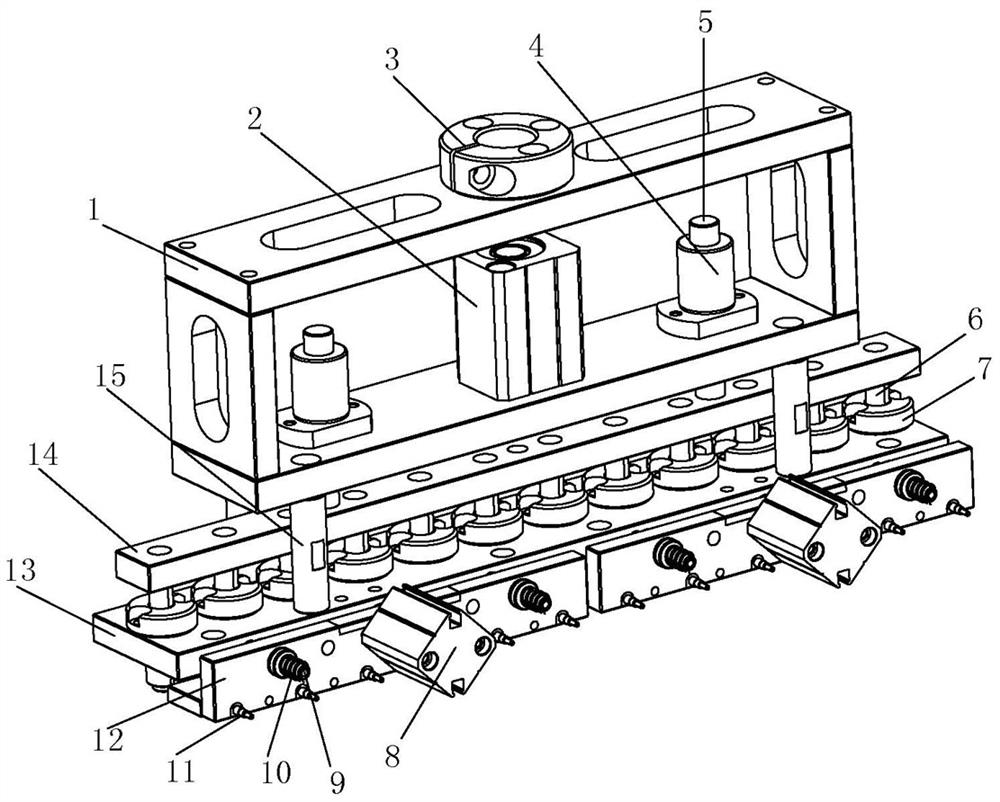

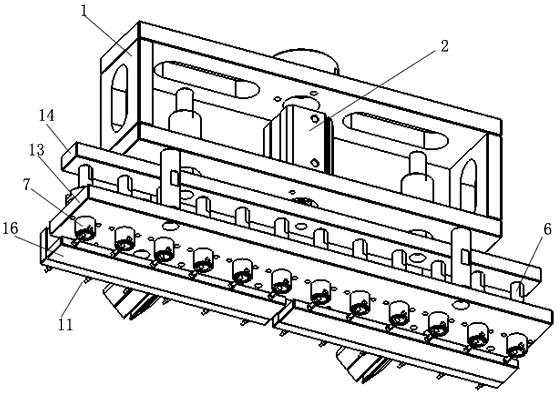

[0019] as attached figure 1 and 2 As shown, the present invention provides an automatic pick-and-place material fixture for manipulators, which can be applied to 4-axis manipulators or manipulators with other axes. This fixture comprises mounting frame 1, and described mounting frame 1 is equipped with fixed plate 13, and fixed plate 13 is provided with several clamping sleeves 7 of hollow structure, and mounting frame 1 is equipped with the jacking material that is used for pressing clamping sleeve 7. Mechanism, fixed plate 13 sides are provided with side push plate 12, and side push plate 12 is provided with side top mechanism, and ejector mechanism presses card material sleeve from top to bottom, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com