Bearing bracket

A bearing bracket, No. 1 technology, applied to the rigid bracket of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of easy loosening of bearing brackets, inconvenient replacement of bearings, and increased production costs of processing plants, etc., to achieve convenient disassembly And the effect of fixing, saving labor force and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

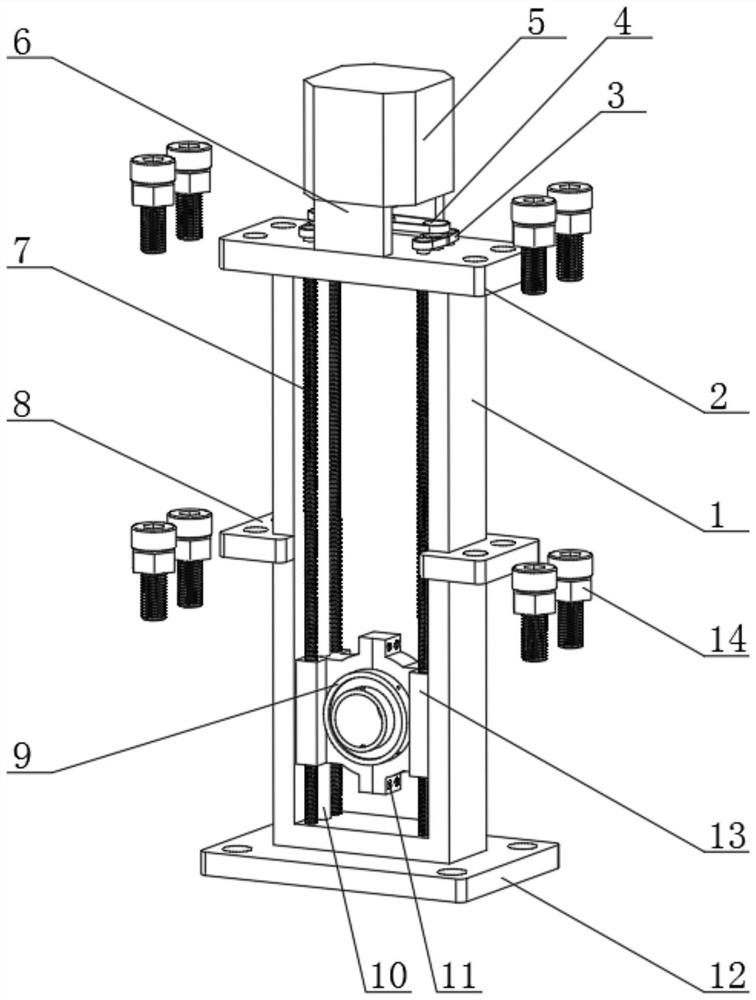

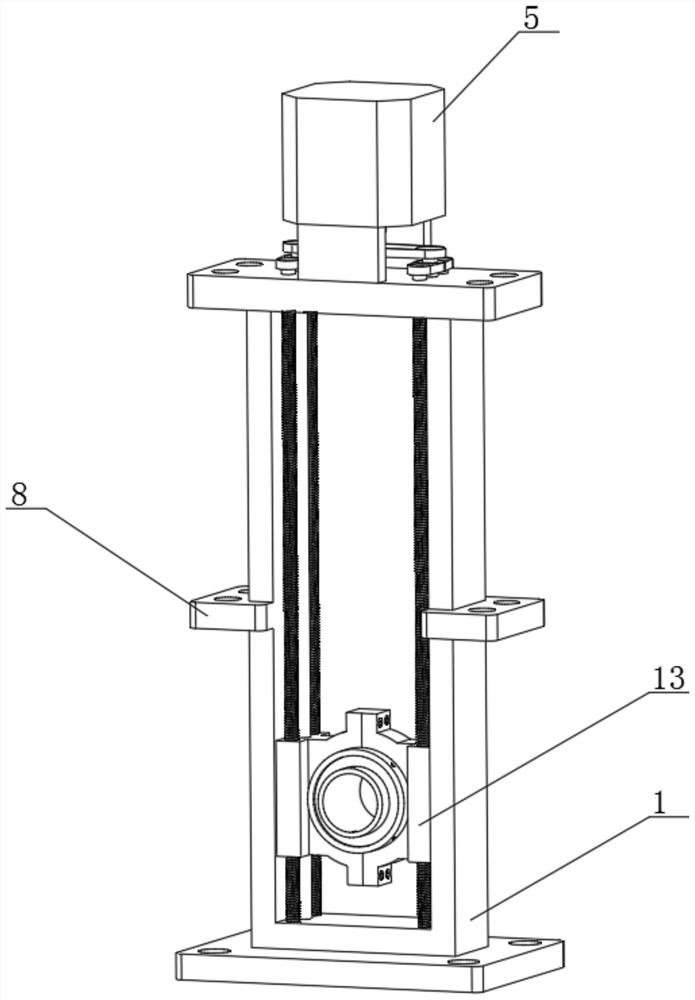

[0028] Such as figure 1 , 3 As shown, a bearing bracket includes a bracket main body 1, a fixed bottom plate 12 is provided on the outer surface of the lower end of the bracket main body 1, a fixing part 8 is arranged on the side end outer surface of the bracket main body 1, and a screw group is arranged on the side end of the fixing part 8 14. The outer surface of the upper end of the bracket main body 1 is provided with a limit cover plate 2, the outer surface of the upper end of the limit cover plate 2 is provided with a fixed plate 6, and the outer surface of the upper end of the fixed plate 6 is provided with a motor 5, and the model of the motor 5 is 42HS02. The upper end outer surface of support main body 1 is provided with No. 1 transmission belt 3 corresponding to the lower end of motor 5, and the upper end outer surface of No. 1 transmission belt 3 is provided with No. 1 transmission wheel 4, and the inner side outer surface of support main body 1 is provided with sl...

Embodiment 2

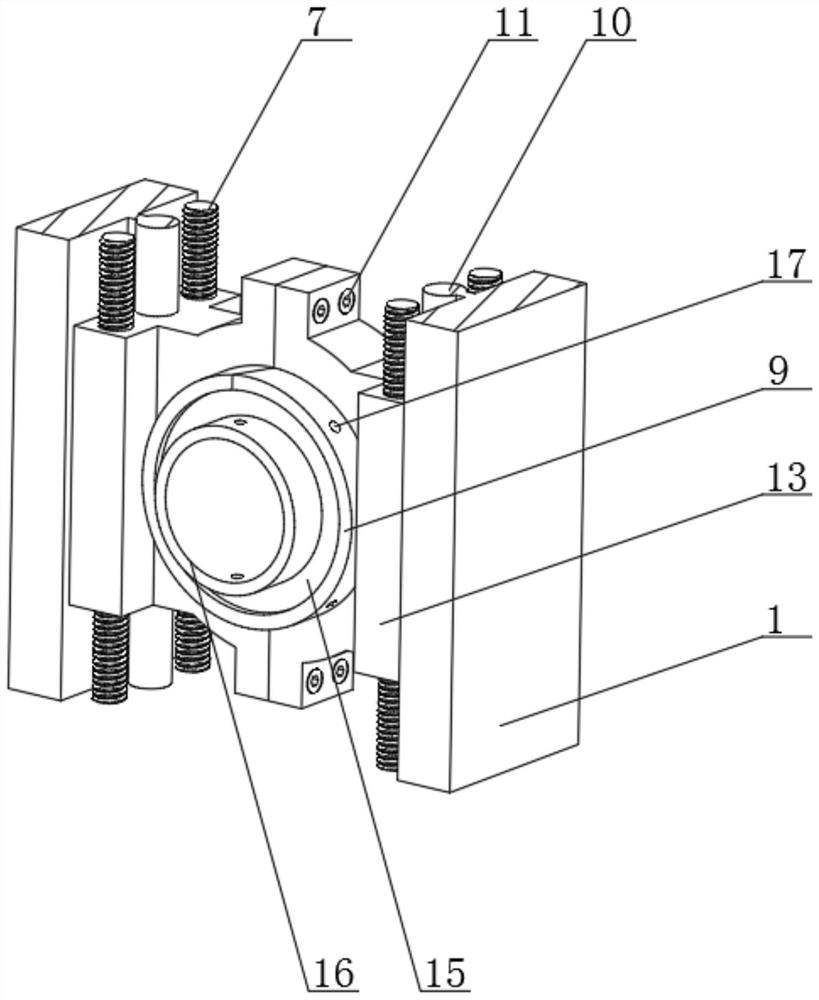

[0030] On the basis of Example 1, as figure 2 , 4 , 5, the lower end of the threaded screw rod 7 is embedded in the inner side of the bracket main body 1, and the two are flexibly connected, and the upper end of the threaded screw rod 7 runs through the limit cover plate 2, and the two are flexibly connected , the number of threaded screw rods 7 is four, and they are arranged in a symmetrical relationship. The outer surface of the left end of the slide bar 10 is attached to the inner outer surface of the bracket main body 1, and the two are fixedly connected. The rotation of the bar 7 can make the slide block 13 slide on the slide bar 10, the slide block 13 is movably connected with the bracket main body 1, the slide bar 10 and the threaded screw rod 7 all run through the slide block 13, and the slide bar 10 and the threaded wire All are movable connection between bar 7 and slide block 13, and the quantity of slide bar 10 and slide block 13 is two groups, and is arranged sym...

Embodiment 3

[0032] On the basis of embodiment one and embodiment two, such as figure 2 , 4, shown in 5, 6, the upper end of connecting shaft is provided with No. 4 transmission wheel 21, and is movable connection between the two, the outer surface of No. 2 transmission wheel 19 and No. 4 transmission wheel 21 is provided with No. 1 transmission belt 3, and three There is a transmission connection between them, the No. 1 transmission wheel 4 is arranged on the upper end of the No. 4 transmission wheel 21, and is fixedly connected between the two, and the lower end of the motor 5 is provided with a connecting shaft, and is a movable connection between the two, and the connecting shaft The lower end of the drive wheel 20 is provided with a No. 3 drive wheel 20, and the two are fixedly connected. The transmission force is generated by the motor 5 and the No. 3 drive wheel 20. The outer surface of the No. 3 drive wheel 20 and the No. 1 drive wheel 4 is provided with a No. 2 drive wheel. Tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com