Motor shell and manufacturing method thereof and motor

The technology of a motor shell and manufacturing method is applied in the motor shell, its manufacturing method and the field of motors, which can solve the problems of inability to apply modularization and poor integrity, achieve superior shock resistance and noise reduction capabilities, simple assembly methods, and integrated good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

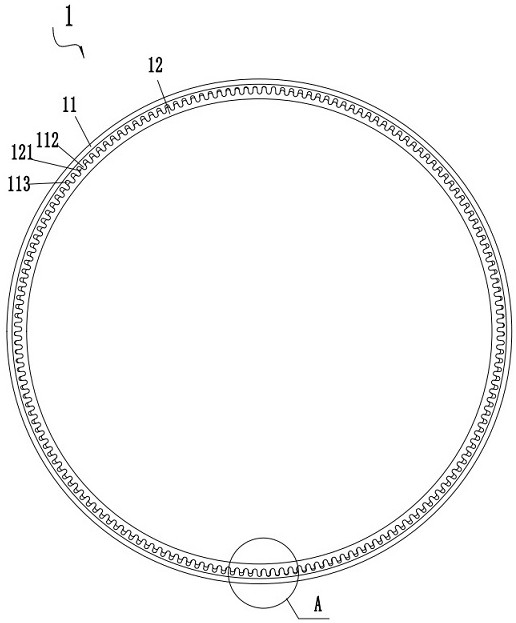

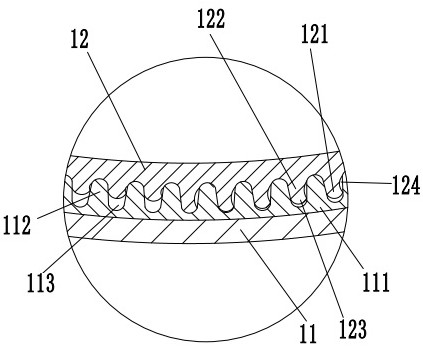

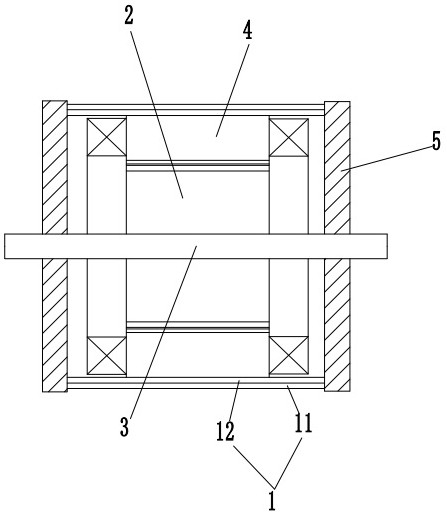

[0028] Such as figure 1 and figure 2 As shown, a motor casing includes a first casing 11 and a second casing 12. The shapes of the first casing 11 and the second casing 12 are cylindrical coaxially arranged, and the second casing 12 passes through It is arranged on the inner side of the first housing 11, and the inner wall of the first housing 11 is provided with several helical tooth ribs 112 arranged along the axis of the first housing 11, and a sound-absorbing groove 113 is formed between adjacent helical tooth ribs 112, The outer side of the second housing 12 is provided with a matching tooth rib 121 arranged in conjunction with the silencer groove 113. One side of the matching tooth rib 121 is attached to one side of the spiral tooth rib 112, and the other side of the matching tooth rib 121 corresponds to this side. A damping medium 124 is provided between opposite sides of the other helical tooth rib 112 . Both the first shell 11 and the second shell 12 can be made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com