Clamp type wrench for circular nut with tooth groove in airplane pipeline

A technology of aircraft tubes and round nuts, applied in the direction of wrenches, screwdrivers, hand-held tools, etc., can solve the problems of inconvenient operation and uneven force on the teeth, and achieve the effects of easy operation, reduced labor intensity, and prevention of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

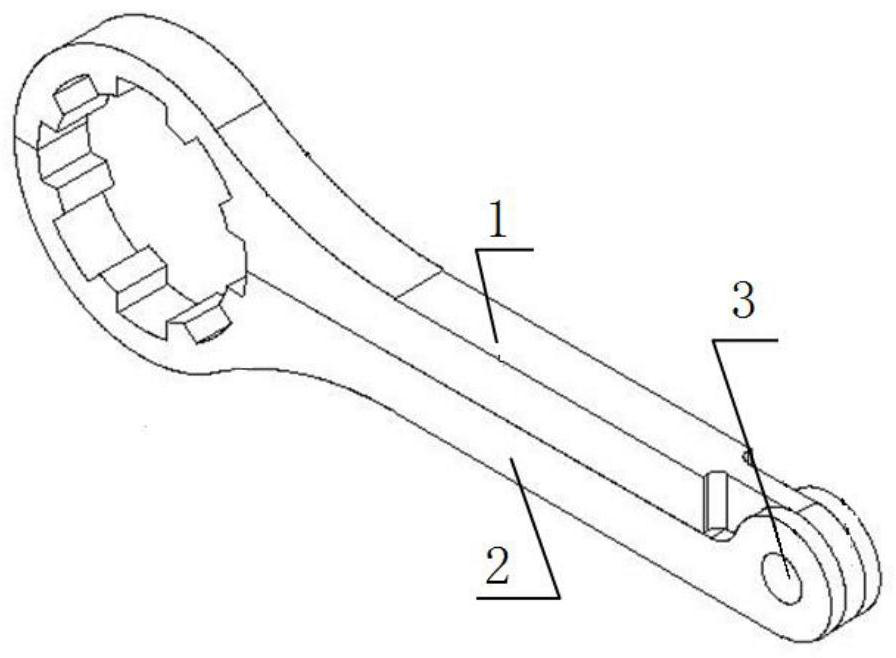

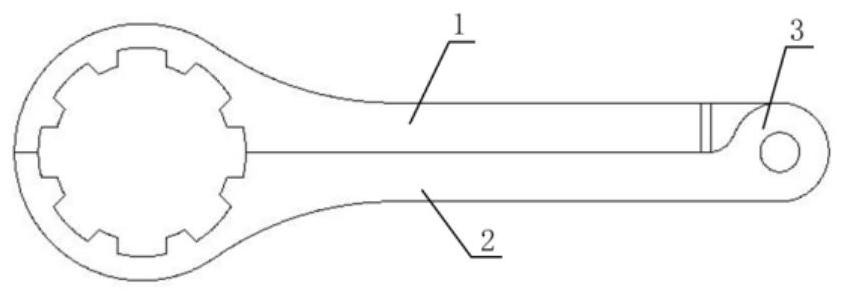

[0039] This embodiment is a clip-type wrench used for round nuts with tooth grooves in aircraft pipelines, including a wrench and a sleeve, and the sleeve is used in conjunction with the wrench. The wrench includes an upper part 1 , a lower part 2 and a connecting piece 3 . The upper connector 6 at one end of the upper part and the lower connector 13 at one end of the lower part are hinged through the connector. The upper clamping end 4 at the other end of the upper part cooperates with the lower clamping end 11 at the other end of the lower part to form a circular clamping head. Described sleeve comprises straight sleeve 16 and right angle sleeve 19, when using this wrench, selects different sleeve for use as required.

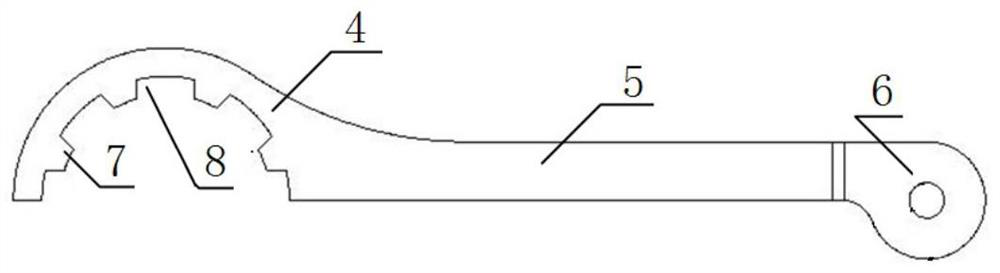

[0040] The upper clamping end 4 of the upper part 1 is semi-circular and used for clamping workpieces. Teeth 7 and tooth grooves 8 are distributed on the inner surface of the upper clamping end. The teeth 7 and the tooth grooves 8 are evenly distributed be...

Embodiment 2

[0053] This embodiment is a clip-type wrench used for round nuts with slots in aircraft pipelines, including an upper part 1 , a lower part 2 and a connecting part 3 . The upper connector 6 at one end of the upper part and the lower connector 13 at one end of the lower part are hinged through the connector. The upper clamping end 4 at the other end of the upper part cooperates with the lower clamping end 11 at the other end of the lower part to form a circular clamping head.

[0054] The structural features of this embodiment are close to those of Embodiment 1, the difference being:

[0055] Teeth 7 and tooth grooves 8 are distributed on the inner surface of the upper clamping end 4 of the upper part 1 . The distribution of the teeth and the gullets is the same as the distribution of the teeth and the gullets in the first embodiment. In this embodiment, the circumferential width of the teeth 7 is 1mm smaller than the circumferential width of the round nut with slots, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com