Self-propelled mechanism and self-propelled mode control method of electric scissor maintenance operation device

A technology of working device and scissors, which is applied in the direction of power steering mechanism, automatic steering control parts, lifting device, etc., and can solve the problems of inability to realize fast operation and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

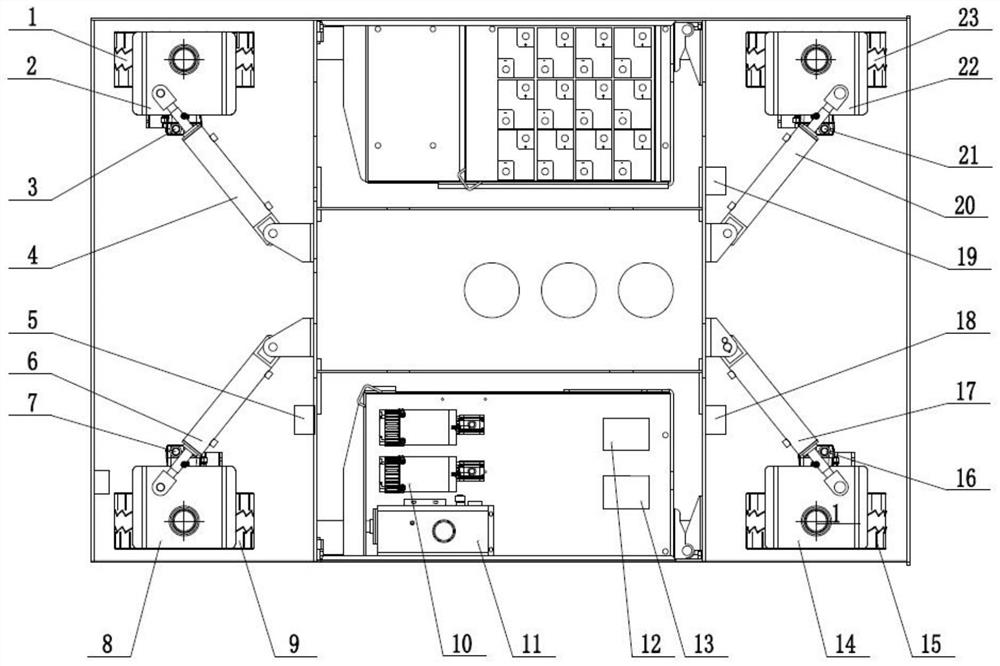

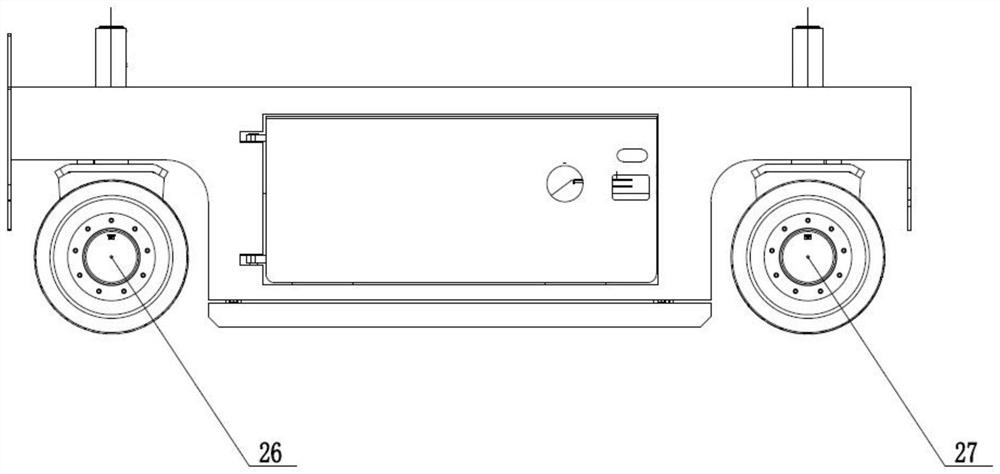

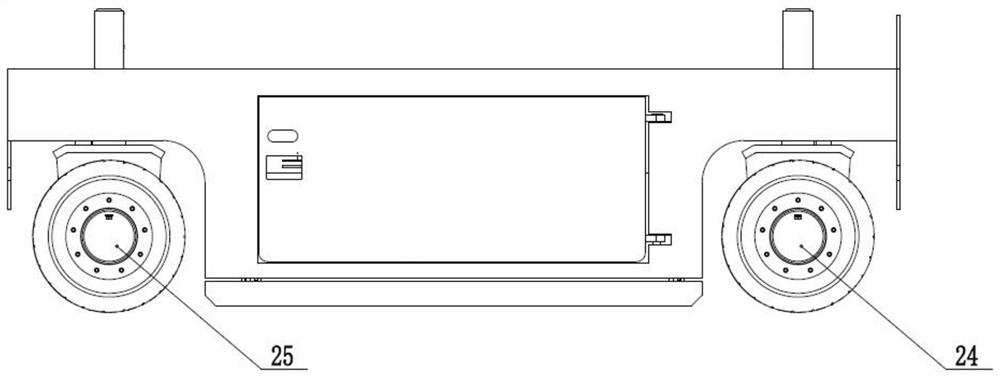

[0035] Example 1, such as Figure 1 to Figure 4 As shown, a self-propelled mechanism of an electric scissor maintenance operation device includes a bogie assembly, a wheel assembly, a drive assembly, a motor power unit 10, an electric control system and a hydraulic system.

[0036] The bogie assembly assembly adopts the steering shaft to be installed on the vehicle frame of the working device. The bogie assembly assembly includes the left rear bogie 2, the right rear bogie 8, the front right bogie 14 and the front left bogie 22, and the left rear bogie Frame 2, right rear bogie frame 8, front right bogie frame 14 and front left bogie frame 22 are identical in structure.

[0037] The left rear bogie 2 comprises a steering shaft 211, a rotating shaft support plate 213, a fixed rotating shaft 212 of the steering cylinder, a motor reducer fixing plate 214 and a rib plate 215 of the motor reducer fixing plate are welded together, and the steering shaft 211 and the fixed rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com