Front cabin frame assembly adopting forked front girder assembly

A technology of frame assembly and components, applied in the connection between superstructure subassemblies, vehicle components, superstructure, etc., can solve the problem of single force transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

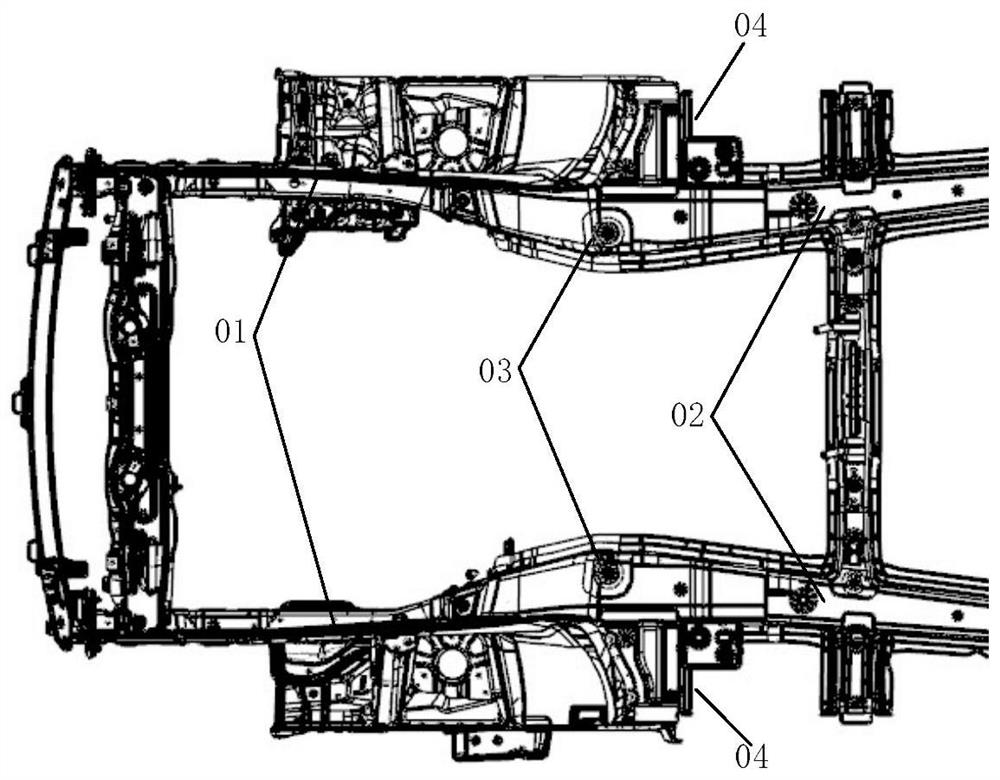

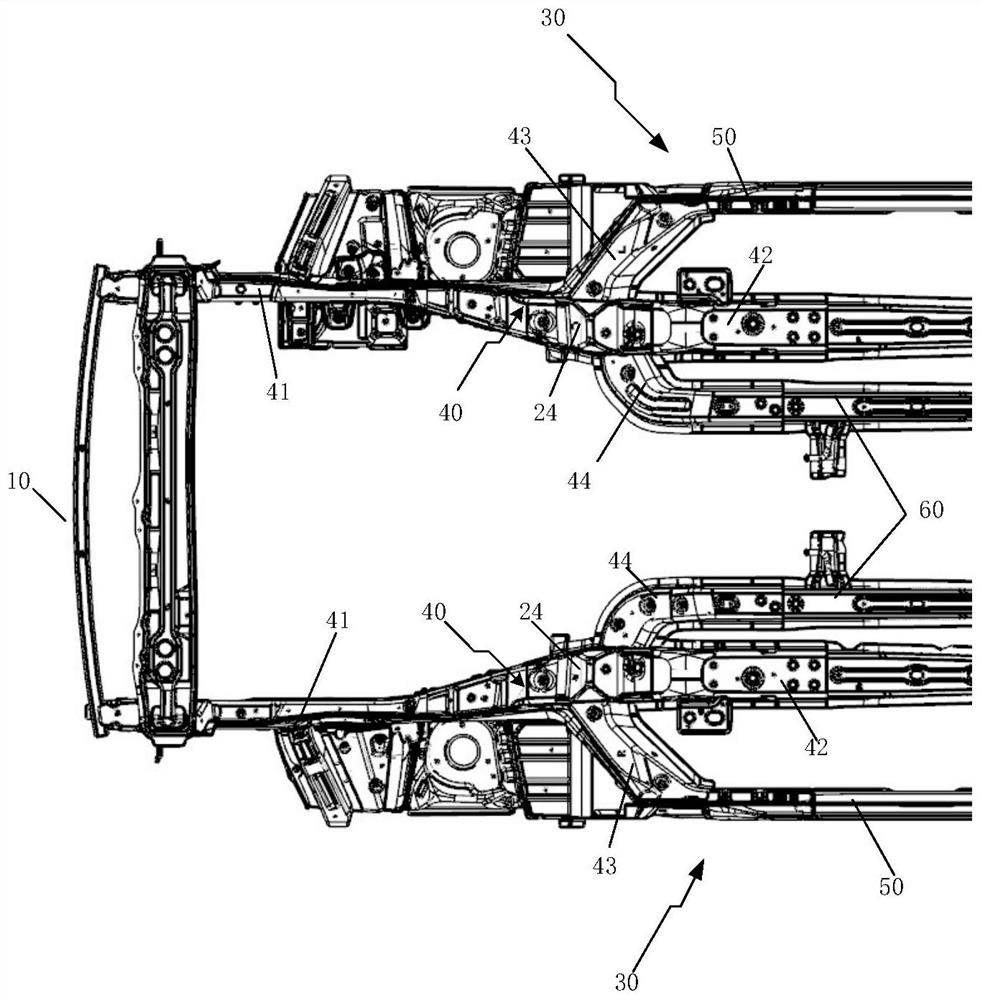

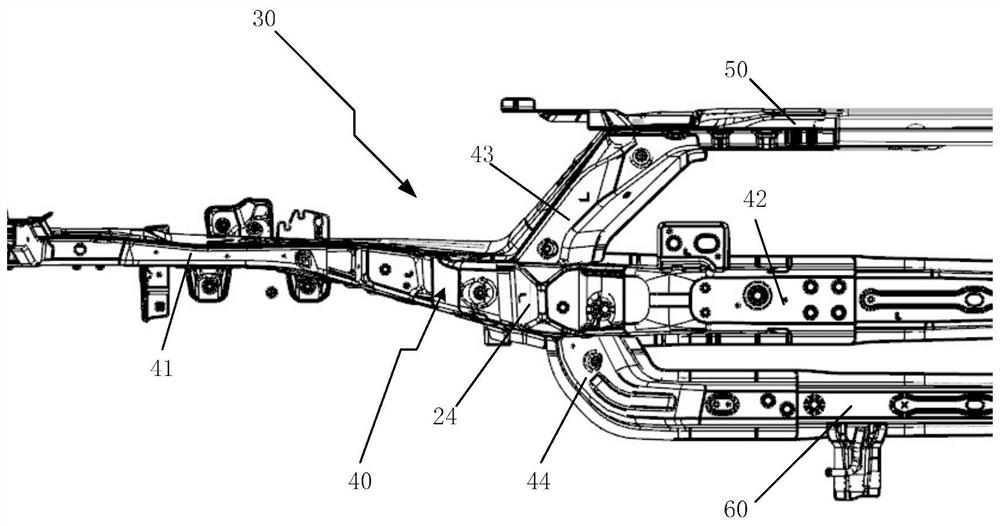

[0040] The following with attached Figure 1 to Figure 12 A front compartment frame assembly adopting a bifurcated front frame assembly of the present invention is further described in detail. figure 1 The left direction is front, the right direction is back, the outward direction is outer, and the inner direction is inner.

[0041] For a front cabin frame assembly using a bifurcated front frame assembly of the present invention, please refer to Figure 1 to Figure 12 As shown, it includes a front anti-collision beam 10, a sub-frame assembly 20, a bifurcated front frame assembly 30 fixed on the rear side of the left and right ends of the front anti-collision beam 10, and the bifurcated front frame assembly 30 includes a front frame Assembly 40 , front compartment outer longitudinal beam gusset 43 and front floor cross member extension 44 , said front compartment outer longitudinal beam gusset 43 is extended and fixed from the outer side of the front part of the front frame as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com