Double-drum washing machine

A washing machine and double-drum technology, applied in the field of washing machines, can solve the problems of high price, high power of direct drive motor, and loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

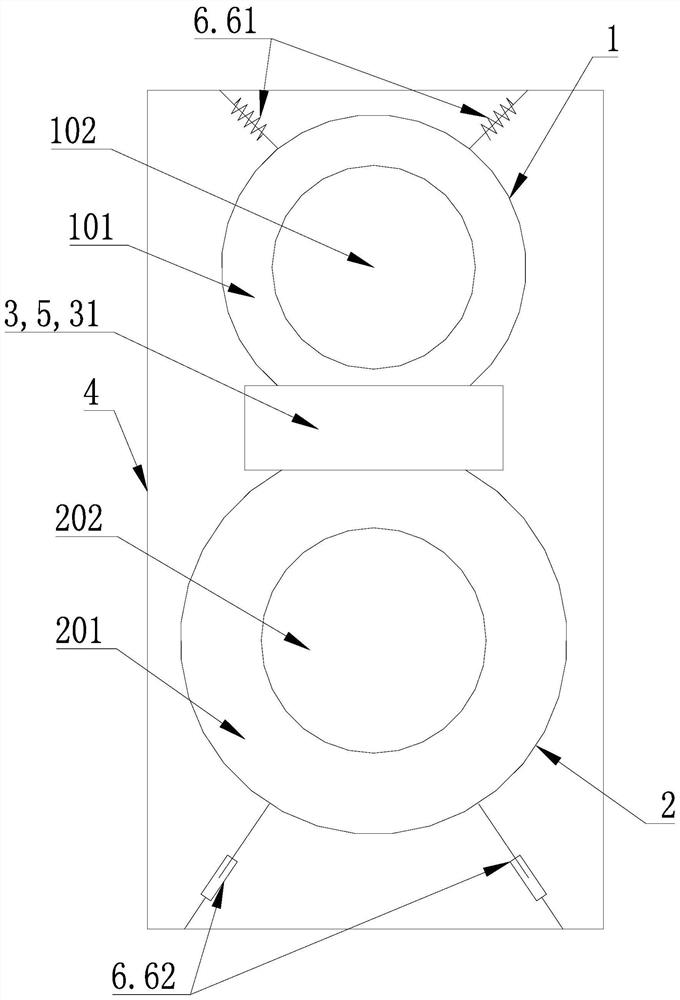

[0061] Such as figure 1 and Figure 6 As shown, in this embodiment, the first outer cylinder 101 and the second outer cylinder 201 are connected as a whole through the connecting piece 3, and the first outer cylinder 101 and the second outer cylinder 201 are located on both sides of the connecting piece 3 Two third accommodation spaces are formed, and the first motor 103 and the second motor 203 are respectively arranged in the two third accommodation spaces.

[0062] Wherein, the first outer cylinder 101 and the second outer cylinder 201 are arranged in the casing 4 from top to bottom, and the two sides of the connecting piece 3 at the connection between the two are formed between the casing 4 and the casing 4 respectively. In the third accommodation space, the two motors are respectively arranged in the two third accommodation spaces. This embodiment utilizes the inner space of the housing 4 rationally, and the structure design is tight without affecting the structure of ...

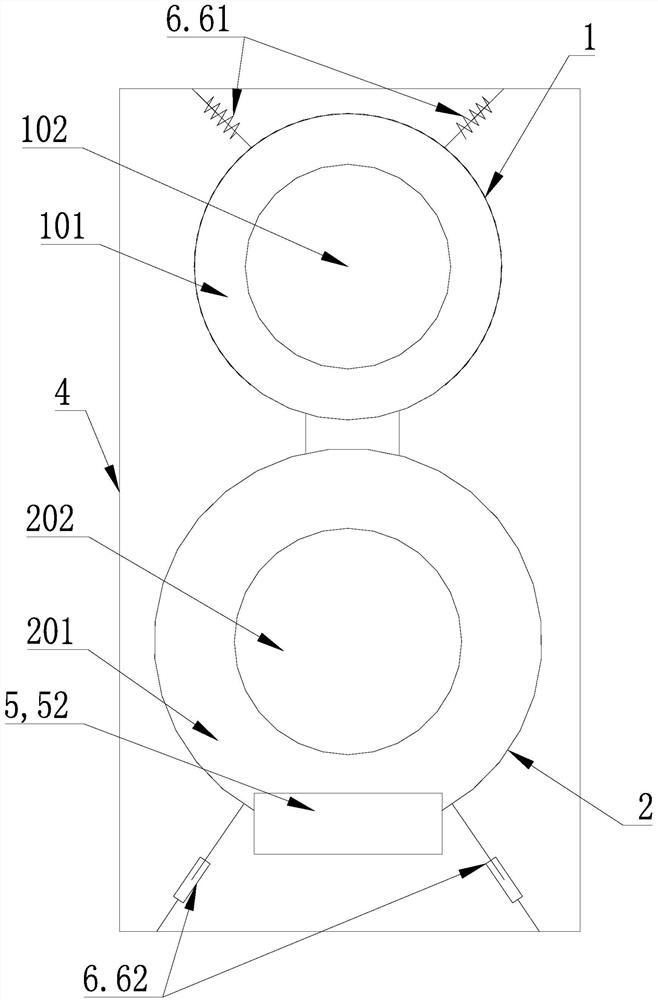

Embodiment 3

[0064] The third embodiment further describes the installation of the motor on the basis of the first and second embodiments.

[0065] In this implementation, the double-drum washing machine includes a housing 4, and the first outer cylinder 101 and the second outer cylinder 201 are sequentially arranged in the housing 4 from top to bottom, and the first motor 103 is fastened to the first outer cylinder through a mounting bracket. On the outer cylinder 101, the second motor 203 is installed on the second outer cylinder 201 through a mounting bracket.

[0066] In another alternative solution, the motor can also be fastened to the housing 4 , specifically, the first motor 103 and the second motor 203 are both fixed on the housing 4 through a mounting bracket.

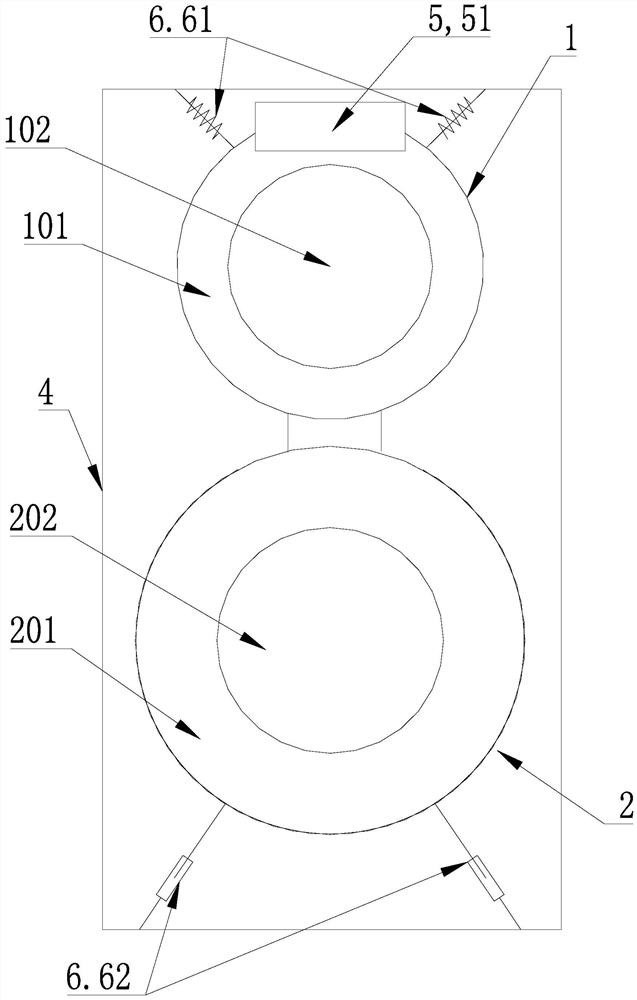

Embodiment 4

[0068] Such as Figure 1 to Figure 6 As shown, on the basis of Embodiments 1 to 3, the present embodiment 4 further analyzes between the first motor 103 and the second motor 203, between the first motor 103 and the second motor 203 and the left and right sides of the washing machine shell 4, the first The limitation of the distance relationship between the motor 103 and the second motor 203 and the upper and lower ends of the washing machine casing 4, the first outer cylinder 101 and the second outer cylinder 201 is based on the premise of effectively reducing the cost of the washing machine and producing an obvious noise reduction effect To achieve the purpose of not affecting the normal operation of the washing machine and not reducing the working efficiency.

[0069] In this embodiment, it includes the first outer cylinder 101 and the second outer cylinder 201 arranged up and down, the first outer cylinder 101 and the second outer cylinder 201 are connected through connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com