A method for reverse assembly of container prefabricated houses

A prefabricated house and container technology, which is applied in the processing of building materials, construction, building construction, etc., to achieve the effect of reducing the intensity of assembly construction work, speeding up the construction speed, and improving the overall construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

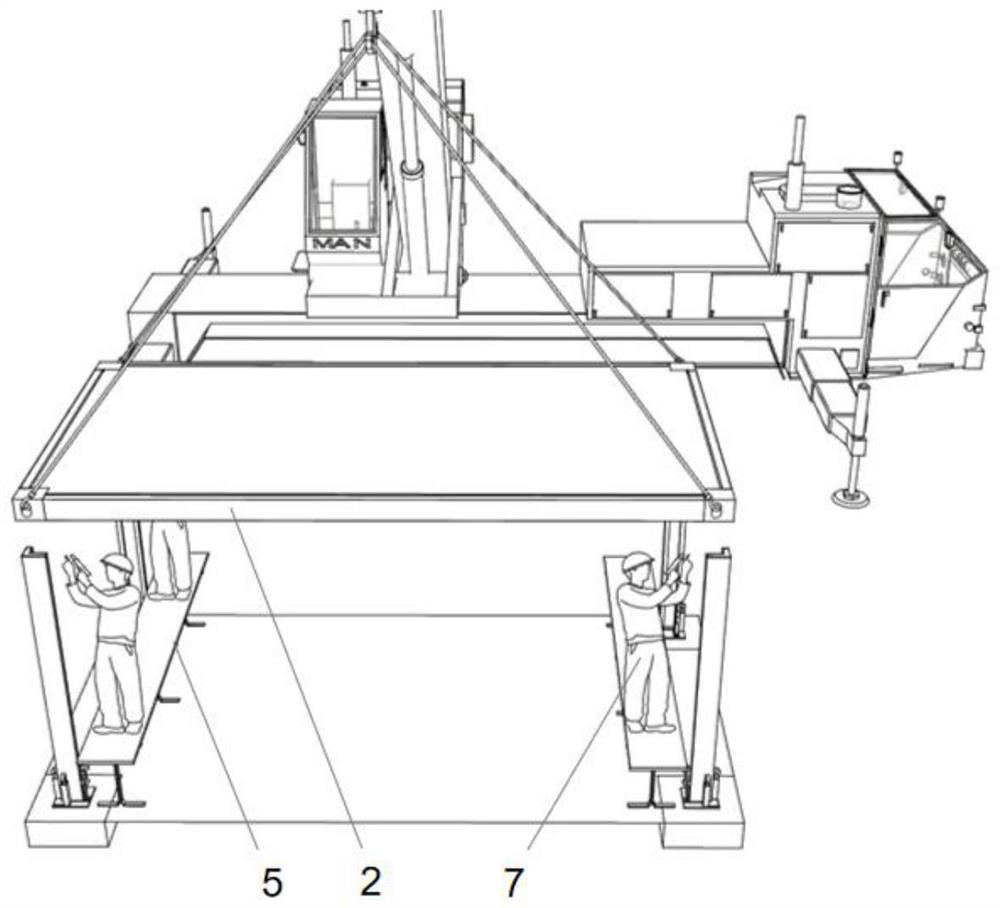

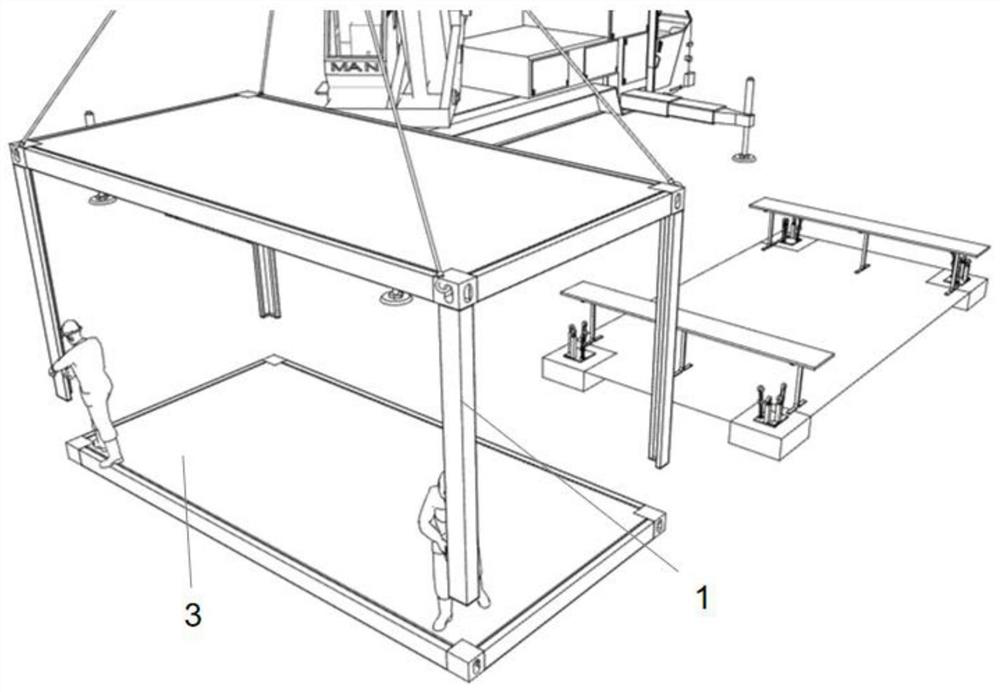

[0049] A method for assembling a structure of a container prefabricated house, adopting a top-to-bottom reverse assembly method, first assembling the container prefabricated house roof 2 and container prefabricated house column 1 together to form a roof column combination, and then assembling the roof post The combined body and the bottom plate 3 of the container prefabricated house are connected as a whole.

Embodiment 2

[0051] Based on embodiment 1, embodiment 2 further defines the assembly method of the above-mentioned container prefabricated house structure, specifically including the following steps:

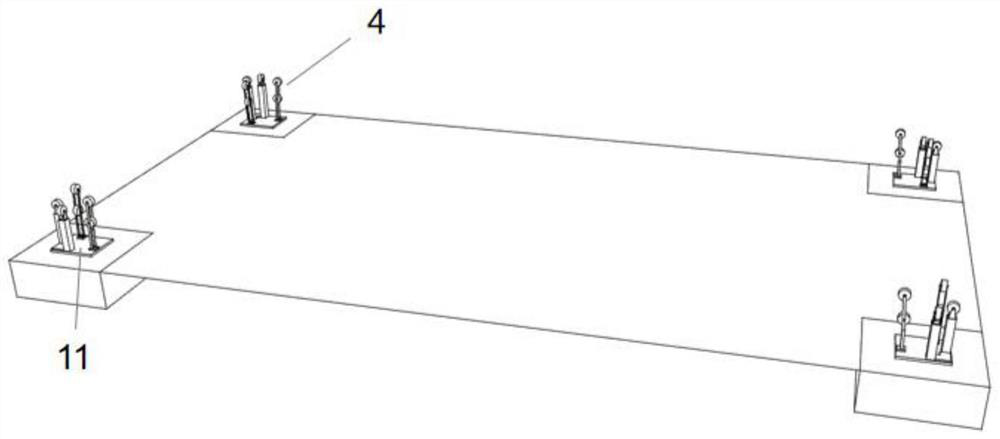

[0052] (1) if figure 1 , choose a suitable location on the project site as the centralized assembly operation place for container prefabricated houses, position according to the size of container prefabricated houses, level the ground, pour columns to quickly locate and align the foundation of fixing devices, and set up an operation platform that does not need to move 5 ;

[0053] (2) if figure 2 , according to the requirements of the column installation operation, fix the column at a suitable position to quickly locate and align the fixing device 4. Of course, the fast positioning and aligning fixing device may not be used, but the crane and the assembling operators need to cooperate and adjust for many times, while the present invention is simpler and labor-saving. There may be only fo...

Embodiment 3

[0058] Based on Embodiment 1, Embodiment 3 provides a different assembly method from Embodiment 2, and further limits the assembly method of the above-mentioned container prefabricated house structure, which specifically includes the following steps:

[0059] (1) Select a suitable location on the project site as the centralized assembly operation place for container prefabricated houses. According to the size and positioning of container prefabricated houses, set up a column auxiliary assembly pit 6 at the assembly position, quickly position the column and align the fixing device 4 Fix it at the bottom of the pit, and then backfill and compact or harden the ground as an activity area for assembly workers.

[0060] (2) Assembling operators can insert the column on the ground into the column quick alignment device 4 in the column auxiliary assembly pit 6 to realize the fixing of the column.

[0061] (3) The crane lifts the roof 2 of the container prefabricated house to the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com