A hoistway module assembly system and assembly method

A technology for connecting wells and modules, applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficulty in allowing the passage and construction of cranes, hindering the normal life of residents, and narrow road space, etc. The effect of easy entry and exit and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

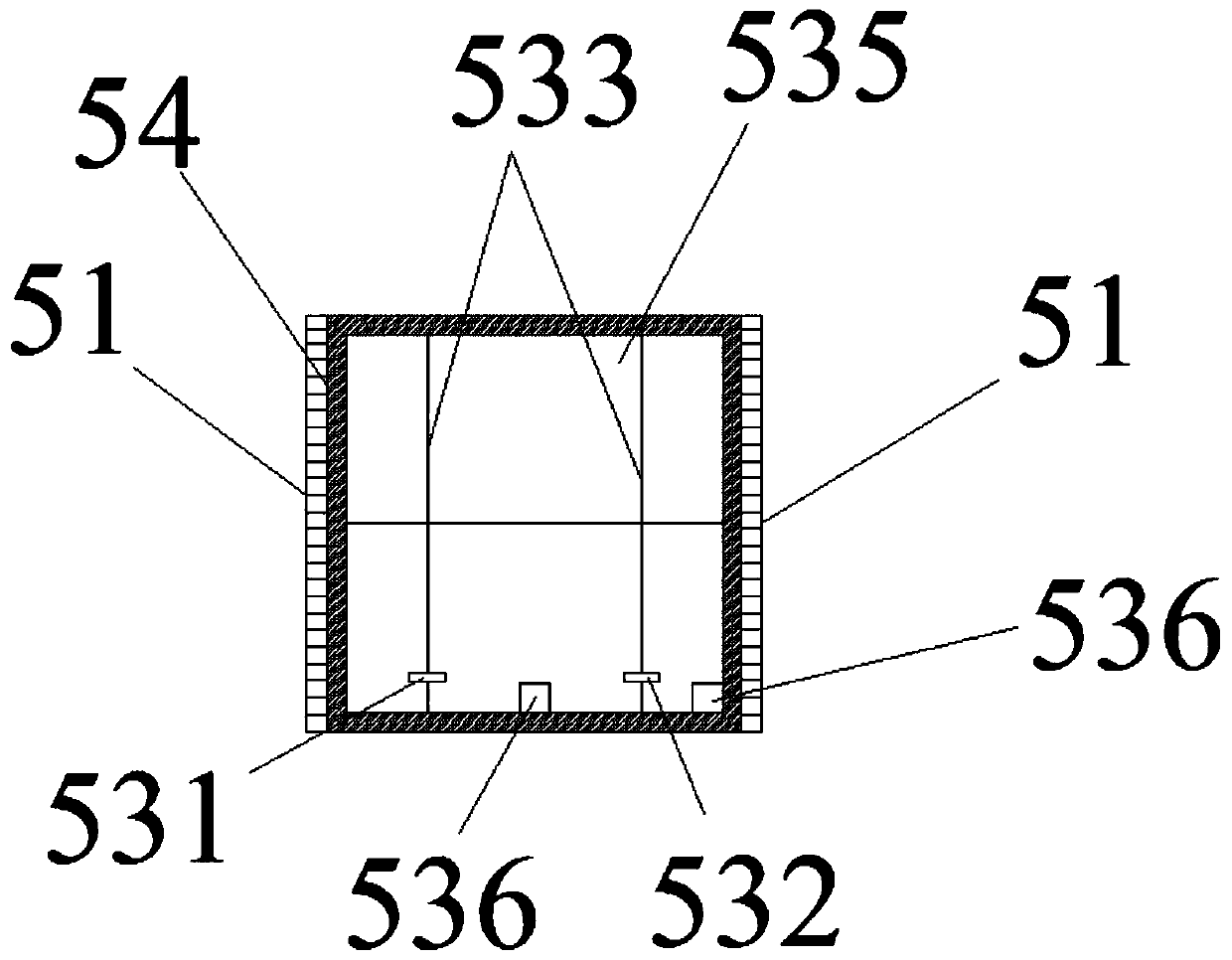

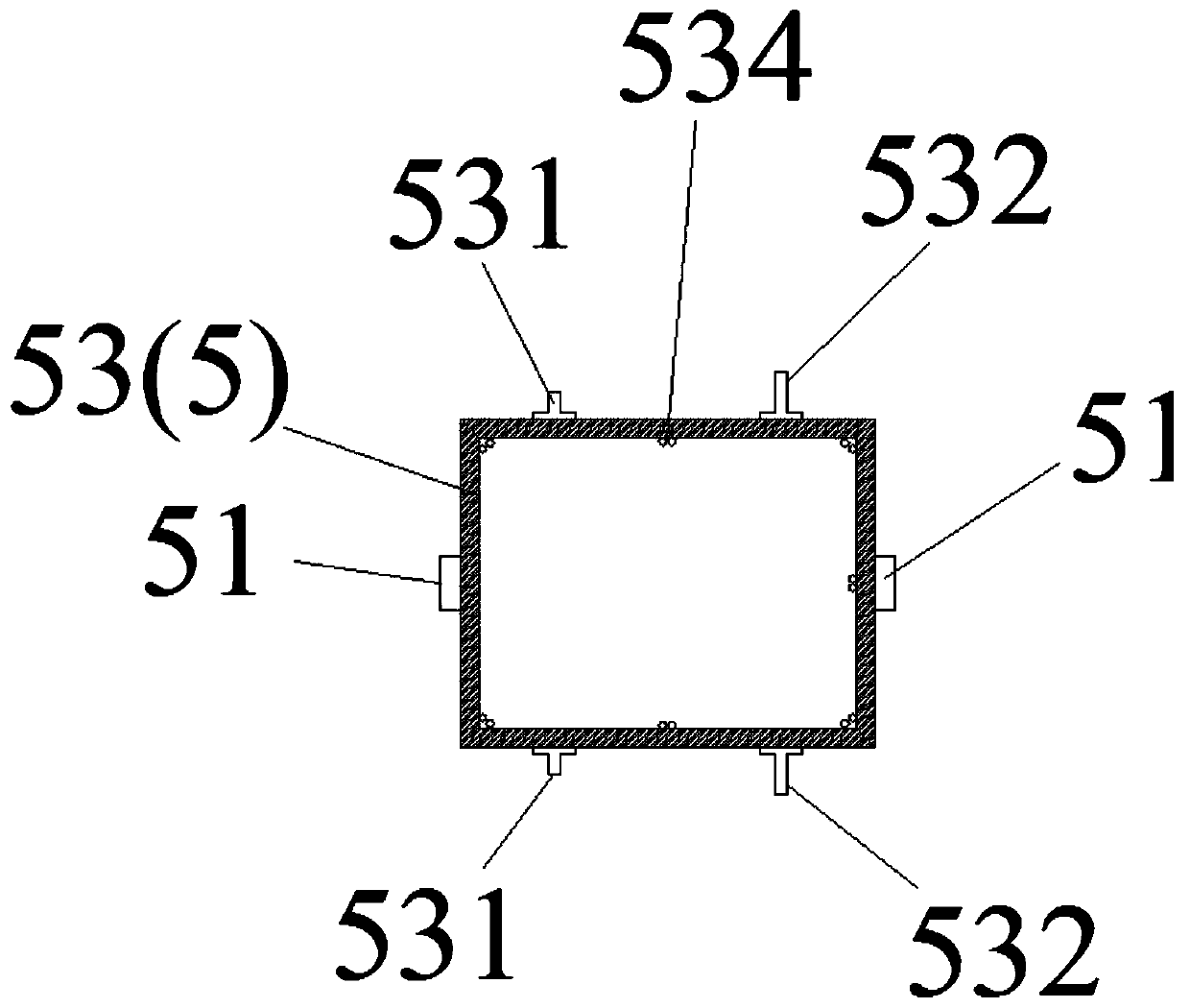

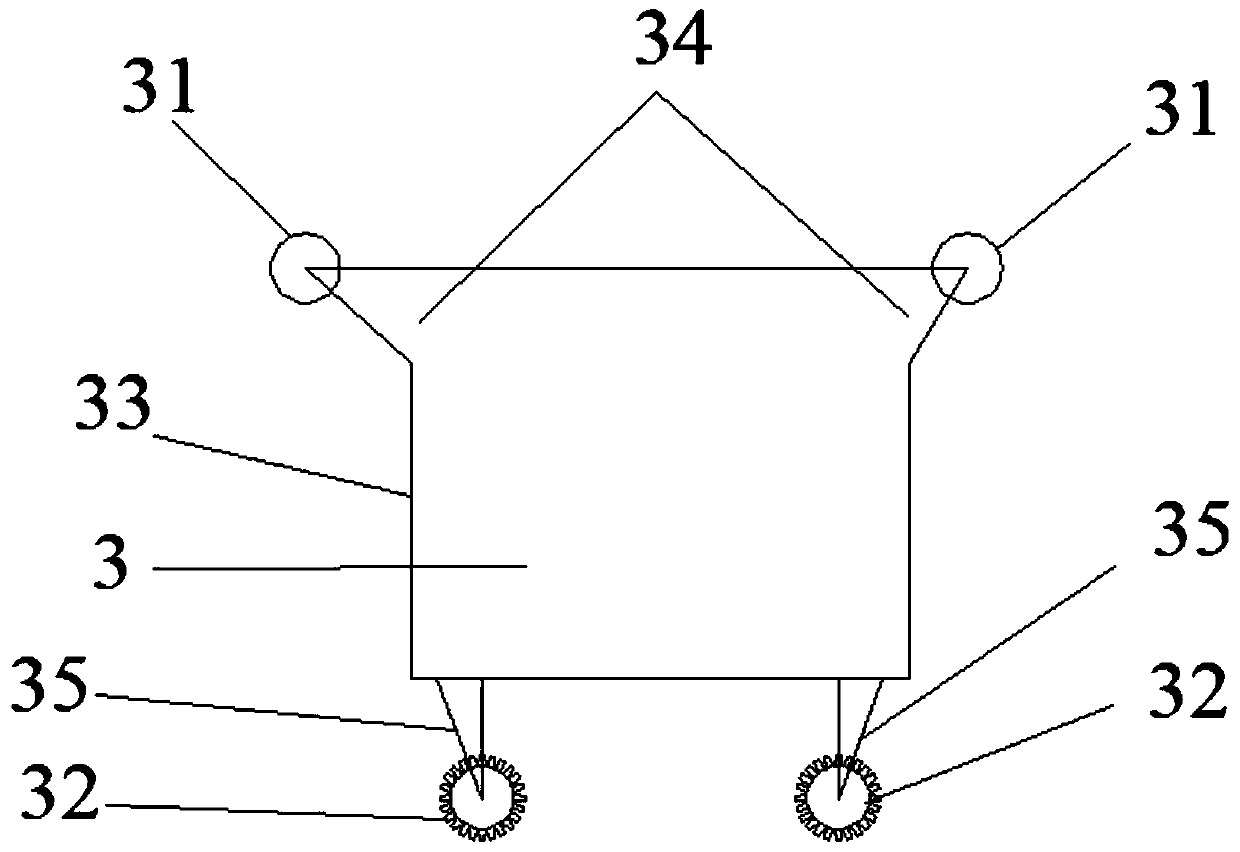

[0060] The invention discloses a hoistway module assembly system, such as Figure 1-9 As shown, it includes a hoist 1, a steel wire rope 2, a temporarily disassembled assembly operation platform 3, and a hoistway module conveying device 4.

[0061] The assembly operation platform 3 is provided with a wire rope guide wheel 31 and a gear 32; the shaft module conveying device 4 is arranged on the assembly operation platform 3; the outer wall of each shaft module 5 is vertically provided with a detachable crawling rack 51;

[0062] The assembled operation platform 3 can be set on the hoistway module 52 that has been assembled (specifically, when the assembled operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com