A kind of arc aluminum formwork and arc plate transportation tool

A technology for transportation tools and aluminum formwork, which is used in transportation and packaging, formwork/formwork components, and on-site preparation of building components, etc., which can solve the problem of uneven pressure on curved plates, single vertical wall structure, and formwork deformation. and other problems to achieve the effect of reducing hidden dangers of deformation, ensuring recoil effect and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

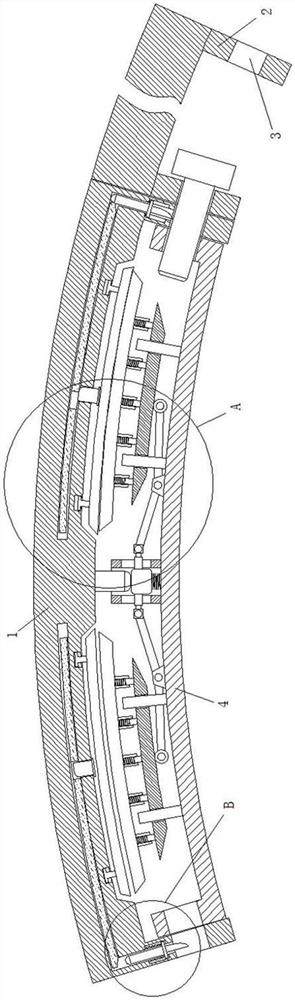

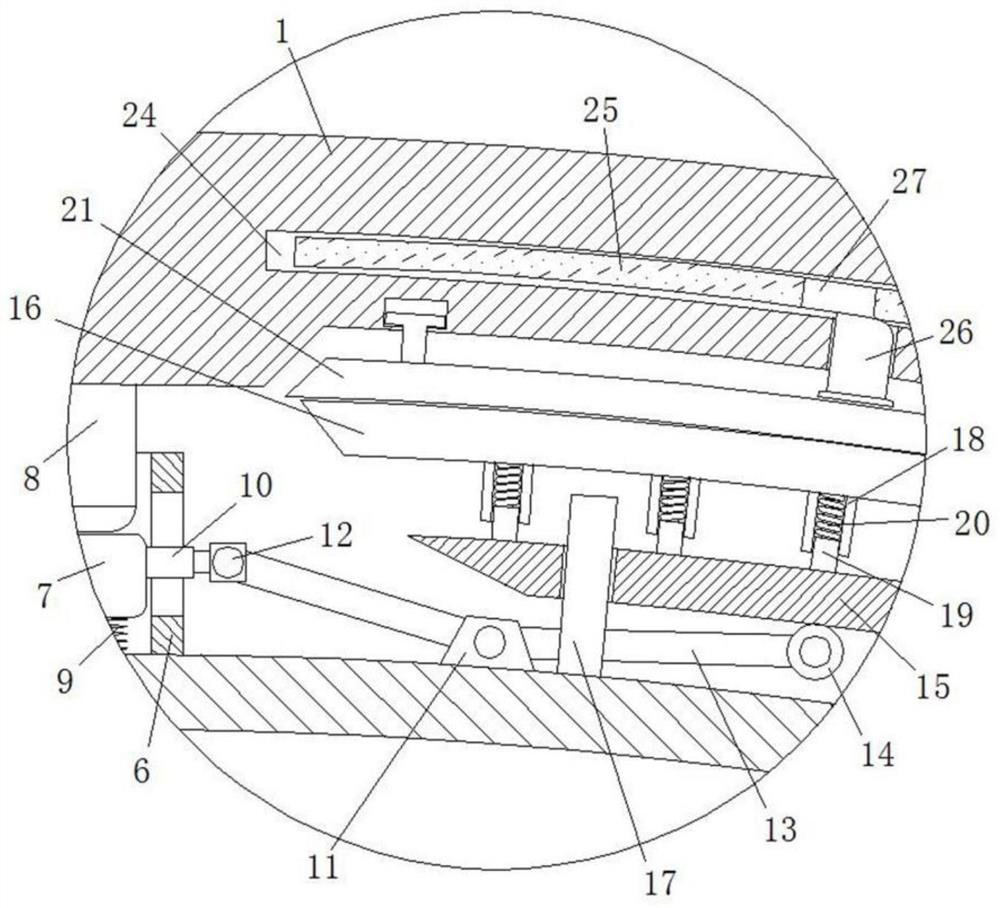

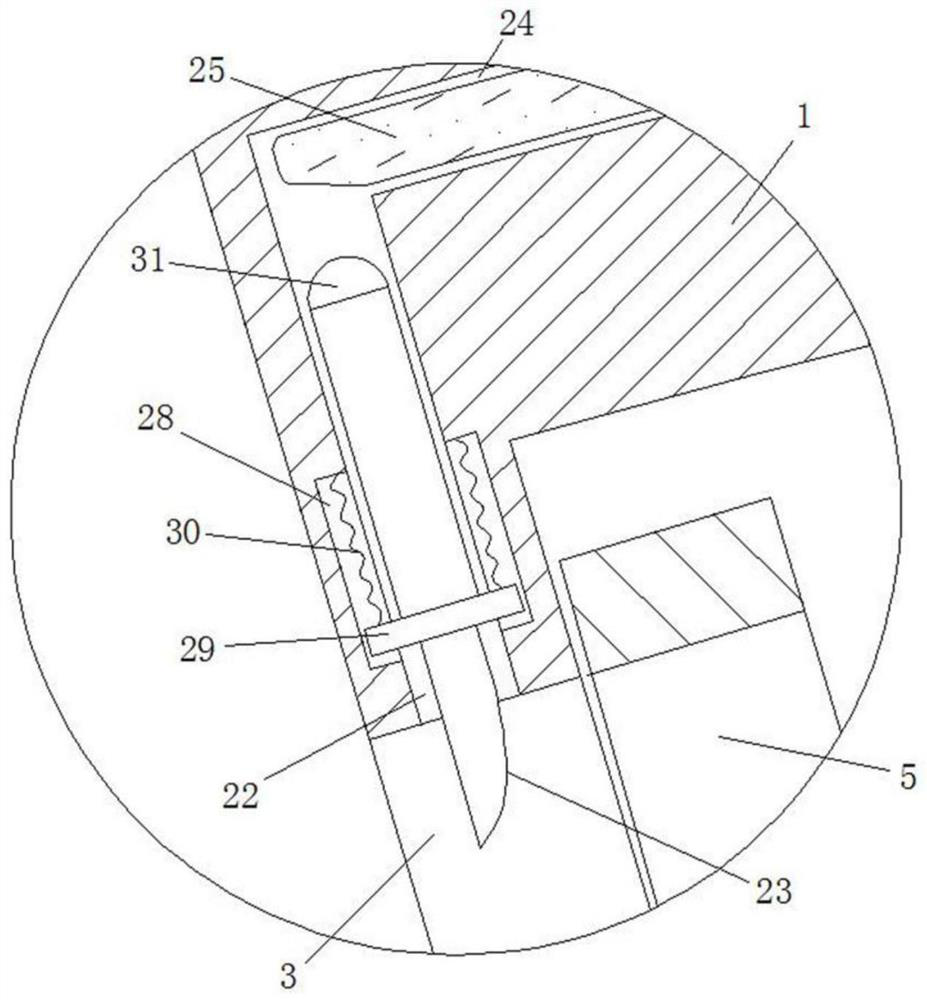

[0036] like Figure 1-3 As shown, an arc-shaped aluminum formwork includes a plate body 1, two ends of the plate body 1 are provided with mounting ears 2, the mounting ears 2 are provided with positioning holes 3, and the plate body 1 is arranged in an arc shape ; The plate body 1 is provided with a recoil plate 4, the recoil plate 4 is provided with a mounting hole 5 that cooperates with the positioning hole 3, and a recoil sliding cylinder is provided in the middle position of the recoil plate 4 6 and a force block 7 slidably arranged in the recoil sliding cylinder 6, the plate body 1 is provided with a pressure block 8 that cooperates with the recoil sliding cylinder 6; the bottom of the recoil sliding cylinder 6 The end is provided with a support compression spring 9, and the support compression spring 9 is fixedly connected with the force block 7; the pressure block 8 is provided with a horizontal sliding rod 10, and the horizontal sliding rod 10 passes through the recoil...

Embodiment 2

[0040] like Figure 4-8 As shown, the present embodiment discloses an arc-shaped plate transport tool, which includes a main frame 32 on which a conveying structure is provided, and the conveying structure includes a support assembly and a power provided on the main frame 32 structure, the support assembly includes two sliding columns 33 arranged on the main frame 32, and end blocks 34 are sleeved on the sliding columns 33; a plurality of support seats are arranged between the two end blocks 34 35. The two ends of the support base 35 are provided with hinge modules, the support base 35 is provided with a support roller 36, the end block 34 is hingedly arranged with the support base 35; The bottom plate 37, the top end of the bottom plate 37 is provided with a supporting arc surface 38 that cooperates with the arc-shaped plate 54; the power structure includes a first transmission wheel 39 arranged between the support components and the first transmission wheel 39 The second tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com