Sleeve type automatic control return valve

A return valve and sleeve-type technology, which is applied in the direction of multi-way valves, valve devices, valve details, etc., can solve problems such as unstable movement of check valves, increase the pressure range, increase stability, and solve valve vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

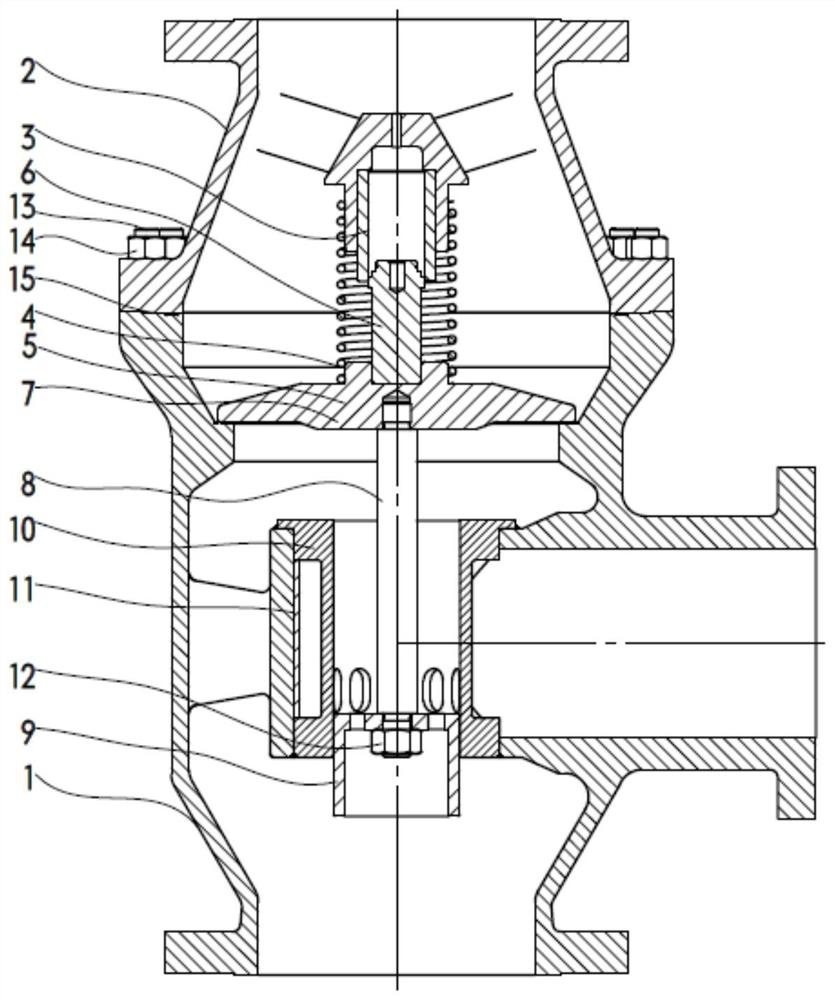

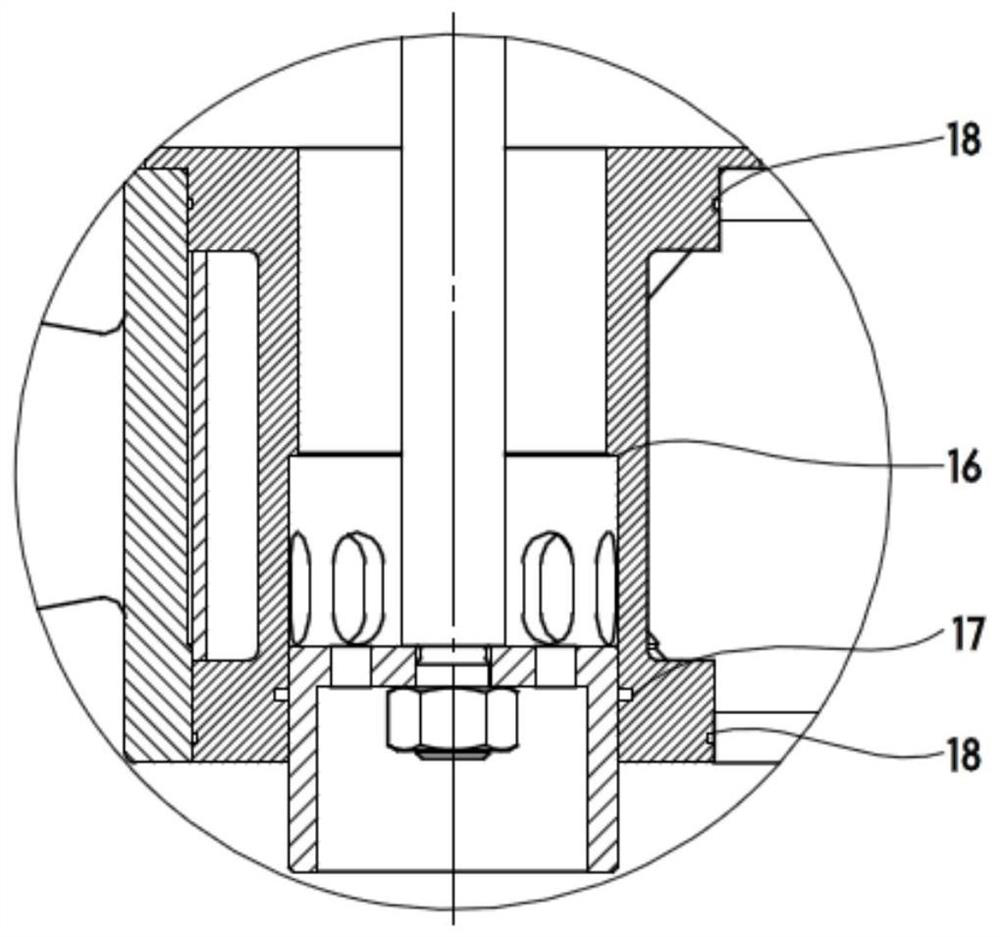

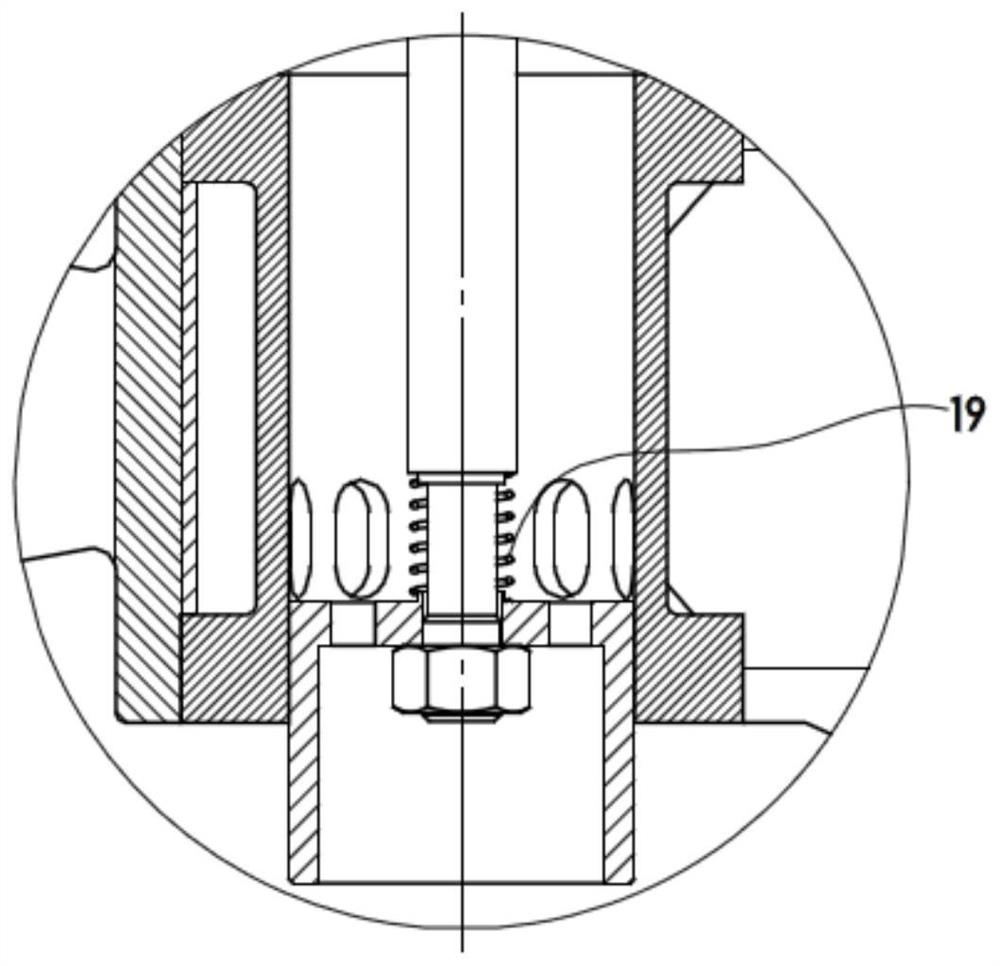

[0035] The invention proposes a sleeve-type self-control return valve. The housing of the self-control return valve is a three-way structure composed of a valve cover and a valve body. The housing is provided with a main circuit valve that communicates with the main road inlet and the main road outlet. A check valve is installed in the valve body, and a main circuit spring is installed between the check valve and the valve cover; a sleeve is installed in the valve body; The valve stem is connected with the upper end of the valve cylinder. The throttling hole of the invention is located on the sleeve of the fixing piece, the main circuit check valve is not affected by the change of the medium flow rate and flow direction at the throttling hole when moving, and the movement is smooth and the stability is high. On the basis of the sleeve-type automatic control return valve, by adding or modifying the internal parts, it can have the functions of bypass without leakage, online adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com