Combustion control system, ignition method, and heat treatment equipment

A control system and controller technology, which is applied in the combustion method, combustion ignition, lighting and heating equipment, etc., can solve the problems of low power point not igniting, product quality problems, and high furnace temperature, so as to achieve stable gas output and avoid Effects of accumulation or excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

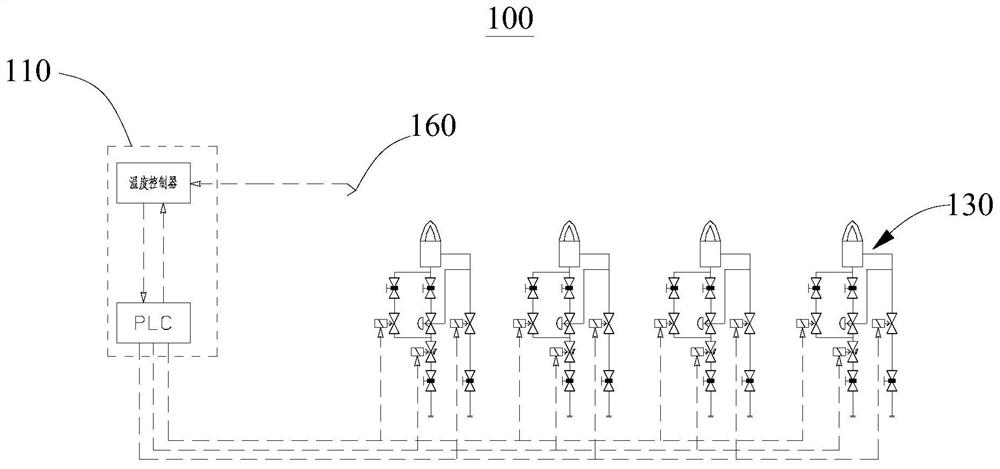

[0035] Please refer to Figure 1 to Figure 3 , this embodiment provides a combustion control system 100, which can ensure successful ignition and is more stable and reliable.

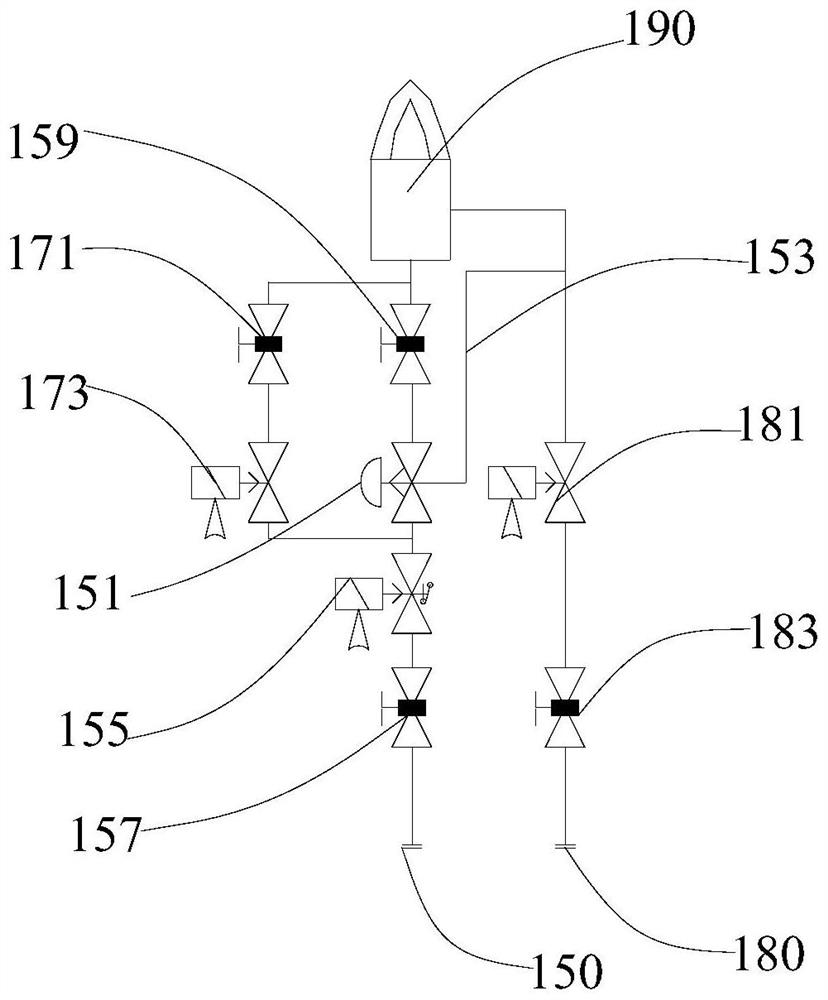

[0036] The combustion control system 100 provided in this embodiment includes a controller 110 and at least one gas control assembly 130. The gas control assembly 130 includes a gas pipeline 150, an ignition pipeline 170, an air pipeline 180 and a burner 190. The burner 190 uses Installed in the furnace body 200, the gas pipeline 150 and the air pipeline 180 are both connected to the burner 190, the gas pipeline 150 is provided with a gas proportional valve 151, and the gas proportional valve 151 is provided with a valve connected to the air pipeline 180 Regulating pipeline 153; two ends of ignition pipeline 170 are respectively connected with gas pipeline 150 on both sides of gas proportional valve 151 to form a branch of gas pipeline 150, and ignition pipeline 170 is provided with ignition solenoid va...

no. 2 example

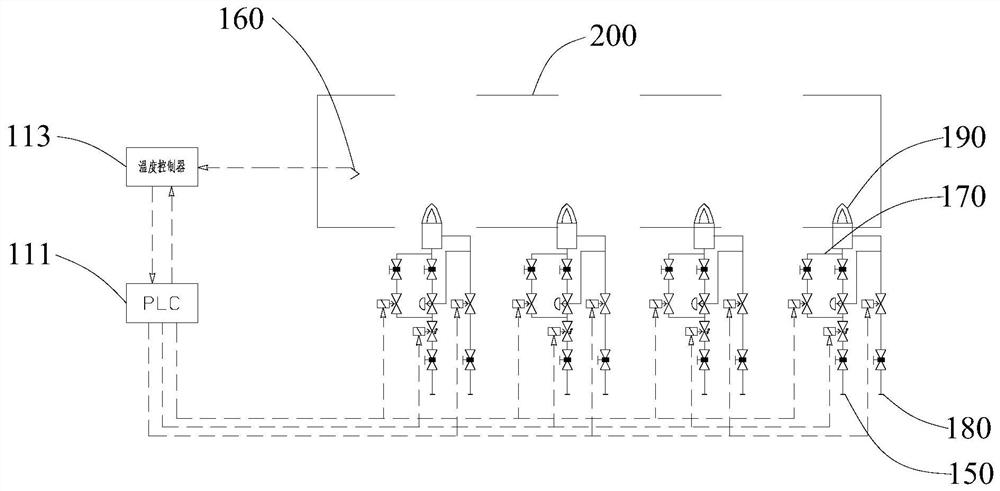

[0066] This embodiment provides a heat treatment device, including a furnace body 200 and a combustion control system 100, wherein the basic structure and implementation principle of the combustion control system 100 are the same as those of the combustion control system 100 provided in the first embodiment, and this embodiment does not mention Reference can be made to the first embodiment here.

[0067] The combustion control system 100 includes a controller 110 and at least one gas control assembly 130. The gas control assembly 130 includes a gas pipeline 150, an ignition pipeline 170, an air pipeline 180 and a burner 190. The burner 190 is used to be arranged on the furnace body 200 Inside, the gas pipeline 150 and the air pipeline 180 are both connected to the burner 190, the gas pipeline 150 is provided with a gas proportional valve 151, and the gas proportional valve 151 is provided with an adjustment pipeline 153 connected with the air pipeline 180; The two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com