An air-cooled cylindrical power battery pack with bionic surface microstructure heat sink

A technology for power battery packs and power batteries, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as poor heat transfer performance, restricting development and application, and low cooling efficiency of air-cooling systems, so as to reduce battery temperature rise, Enhance thermal stability and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

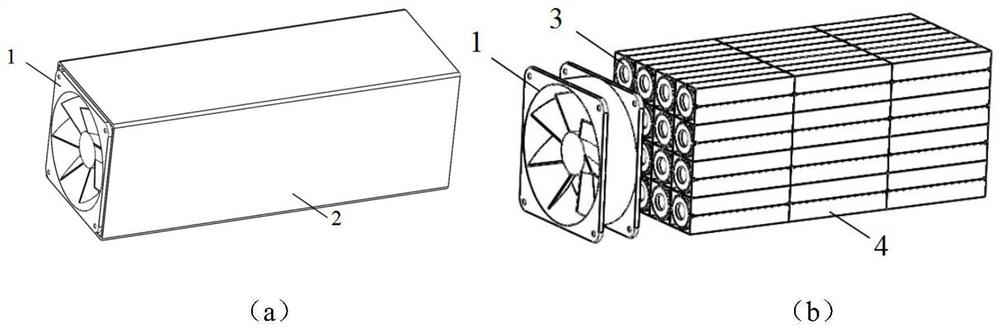

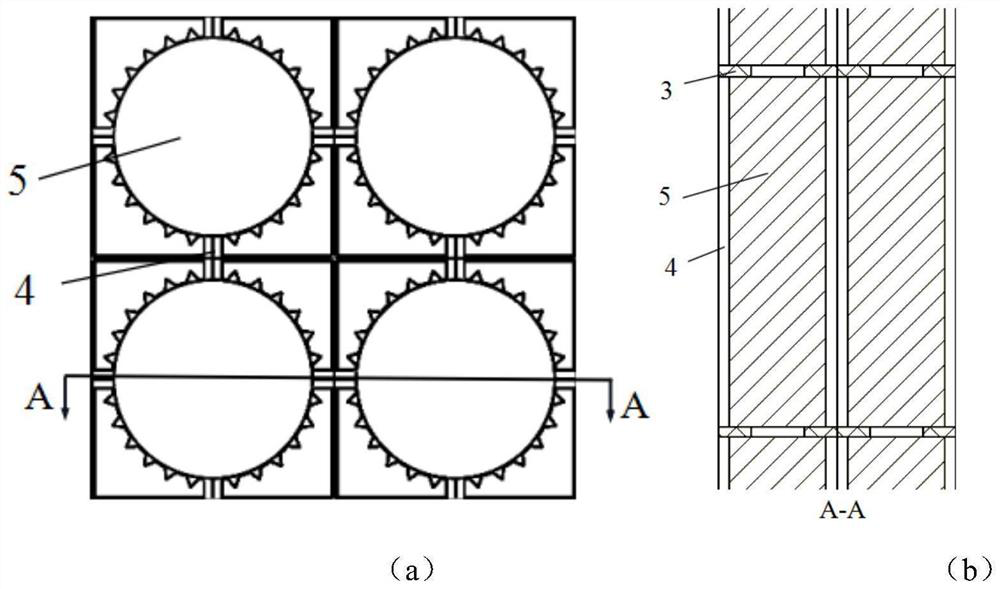

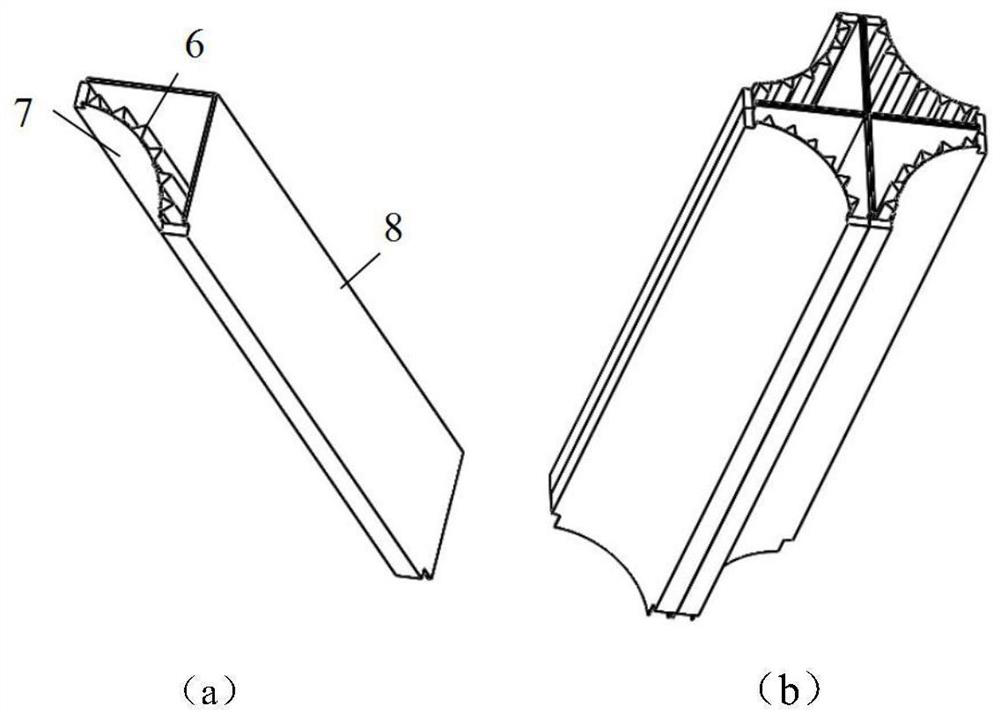

[0027] An air-cooling cylindrical power battery pack containing a bionic surface microstructure heat (including fan 1, housing 2, insulating frame 3, bionic surface microstructured heat sink 4, cylindrical power battery 5. The outside air is driven by the fan 1, and enter the battery module, flowing out of the other end of the battery pack after passing through the multilayer cylindrical power battery 5. The bionic surface microstructured heat dissipator 4 has an arc surface 7 and a right angle surface 8, and the diameter of the arc surface 7 is in diameter as the cylindrical power battery 5, and the outer side of the arc surface 7 is in contact with the cylindrical power battery 5, and the intermediate thermally conductive glue is excluded. Air, increase thermal conductivity. Between the four bionic surface microstructured heatns 4, the space between the cylindrical power cells 5 is embedded after contact with the vertical angle surface 8, and the air-cooling heat dissipation eff...

Embodiment 2

[0031] The present invention has an effect of heat dissipation for the cylindrical power battery pack, and the 18650 cylindrical battery 5 in the present invention may be a cylindrical battery such as 26650, 26650, 32650. At the same time, the present invention is equally applicable when the battery distribution spacing and arrangement are changed.

Embodiment 3

[0033] The cross section of the bionic surface microstructure 6 can be a rectangular or triangular or trapezoidal or elliptical shape, and the height of the bionic surface microstructure 6 is 0.4-1.4 mm, and the spacing S of the bionic surface microstructure 6 is twice the height H. The three-layer bionic surface microstructured heat dissipation 4 axially combined, after the battery pack is installed, the integral axial length L is 41-201 mm. According to the use of the battery module, when the wind speed is 0.8 m / s, the cross-sectional shape, height, and overall length of the bionic surface microstructure 6 can be performed accordingly.

[0034] When the cross-sectional shape and overall length of the bionic surface microstructure 6 are triangles and 201 mm, with the increase in the microstructure height, the highest temperature and maximum temperature difference of the battery module gradually decrease. When the microstructure height increases from 0.4 mm to 1.4 mm, the highes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap