Power distribution cabinet with safety protection function

A technology for safety protection and power distribution cabinets, applied in substation/distribution device casings, electrical components, substation/switch layout details, etc. Efficiency, the effect of automatic control improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

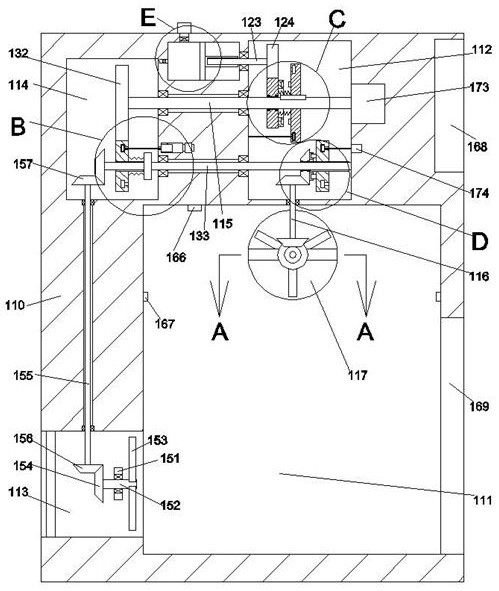

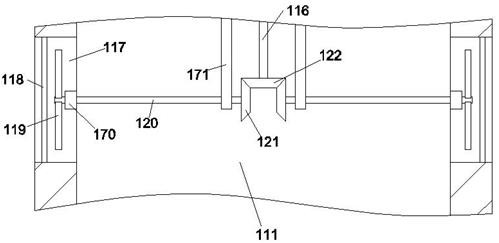

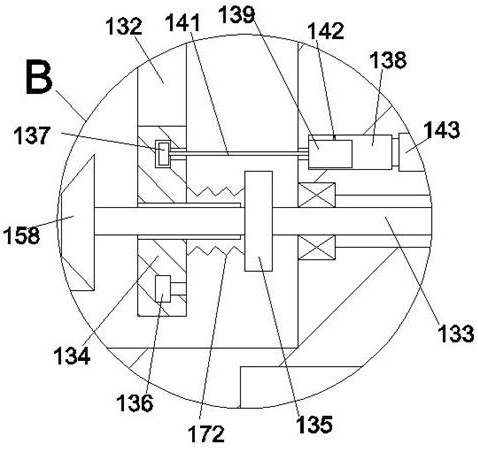

[0030] The rotation of the third rotating shaft 115 is controlled by the drive motor 173, and then the third rotating shaft 115 drives the first gear 132 to rotate. At this time, the third gear 134 and the fourth rotating shaft 133 are driven by the first gear 132 to rotate. At the same time, the fourth rotating shaft The third bevel gear 158 on the left side of 133 drives the sixth bevel gear 157 and the seventh bevel gear 156 at the bottom of the sixth rotating shaft 155 to rotate, thereby realizing the rotation of the seventh bevel gear 156 and the first fan blade 153 to realize the air intake 113 At the same time, because the second bayonet turntable 144 is connected with the second bayonet ring block 149, at this time, the second bayonet ring 144 drives the second bayonet ring block 149 and the fourth bevel gear 148 At the same time, the fourth bevel gear 148 drives the fifth bevel gear 150, the sixth bevel gear 122 and the second bevel gear 121 at the bottom of the fifth ...

Embodiment 2

[0032] The telescopic rod 147 is controlled by the telescopic controller 174 to drive the second bayonet turntable 144 away from the second bayonet ring block 149, so that the driving motor 173 controls the rotation of the third rotating shaft 115, and then the third rotating shaft 115 drives the first gear 132 to rotate. At this time, the third gear 134 and the fourth rotating shaft 133 are driven by the first gear 132 to rotate, and at the same time, the third bevel gear 158 on the left side of the fourth rotating shaft 133 drives the sixth bevel gear 157 and the seventh bevel gear at the bottom of the sixth rotating shaft 155. The bevel gear 156 rotates to drive the seventh bevel gear 156 and the first fan blade 153 to rotate to realize the air intake control work of the air inlet 113. At this time, the second fan blade 119 is in a static state to realize the air outlet 117. Normal exhaust work, reduce energy consumption;

Embodiment 3

[0034] When a fire broke out in the equipment cavity 111, at this moment, the fire detection sensor 166 sends a signal and controls the electromagnetic coil device 143 to open, so that the magnetic movable block 139 and the electromagnetic coil device 143 generate suction and move to the right, and then the magnetic movable block 139 The third gear 134 is driven by the first pull cord 141 to overcome the top pressure of the second spring 172 and stay away from the first gear 132. At the same time, the magnetic movable block 139 drives the first latch turntable 128 to overcome the first spring 131 through the second pull cord 142. The top pressure is connected with the ring block 127 of the first slot, and then the third rotating shaft 115 is controlled by the drive motor 173 to rotate, and the ring block 127 of the first slot and the second gear 125 are driven by the first tooth turntable 128 to rotate. , the second gear 125 drives the fourth gear 124 and the push screw 123 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com