Hybrid battery component and method for producing hybrid battery component

A hybrid battery and battery assembly technology, applied in battery pack parts, secondary battery manufacturing, electrical components, etc., can solve the problems of expensive prismatic battery cells, components that cannot be integrated into the casing, etc., and achieves the highest risk of spillage. , the effect of reducing the risk of spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

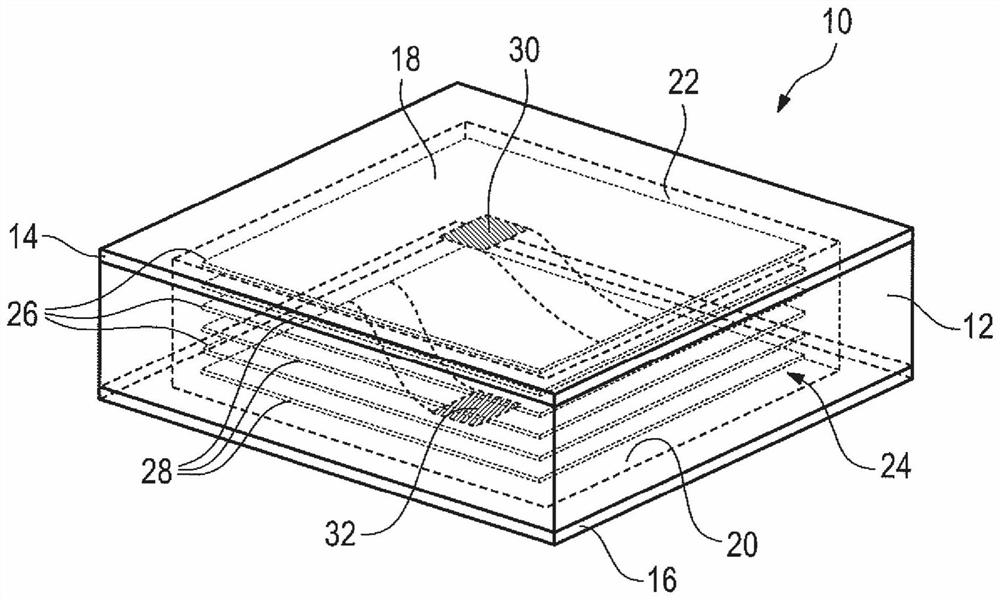

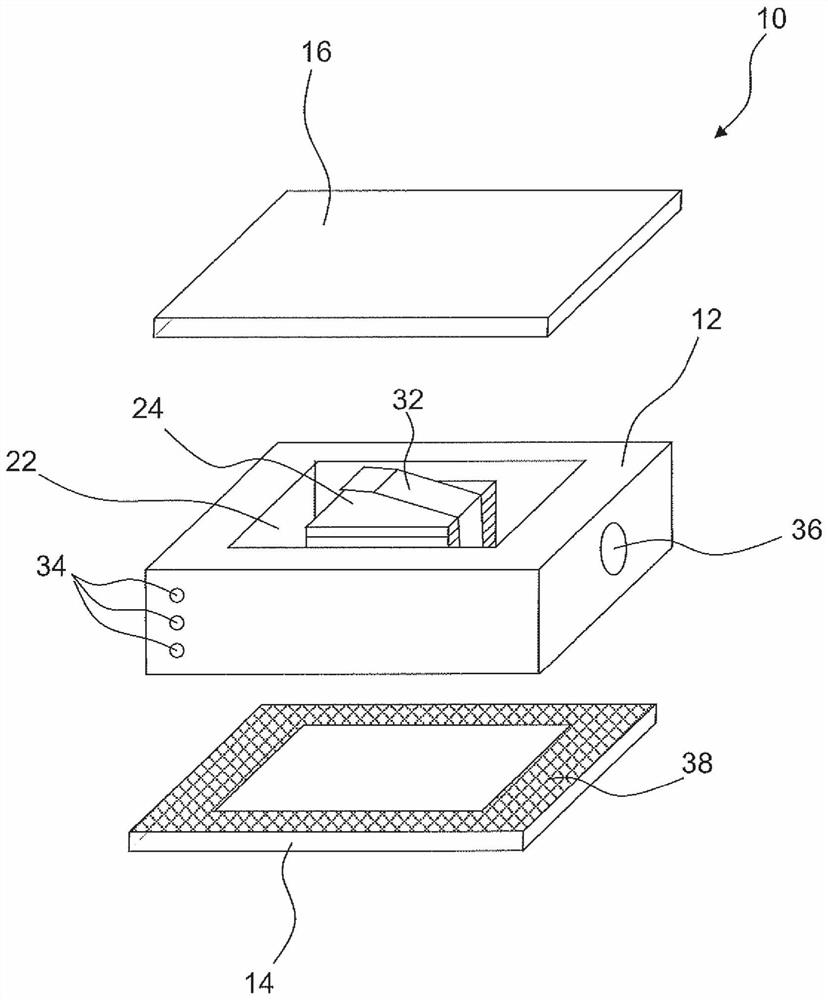

[0024] figure 1 A hybrid battery assembly 10 according to the invention is shown, which has a plastic housing 12 open on both sides and two covers 14 , 16 made of metallic material. Here, the first cover 14 covers the first opening 18 of the plastic housing 12 in a fluid-tight manner, and the second cover 16 covers the second opening 20 of the plastic housing 12 in a fluid-tight manner, so that a closed interior space 22. The inner space is filled with an electrolyte solution. In the embodiment shown, the plastic housing 12 is designed as a rectangular frame. Preferably, the plastic housing 12 is an injection molded part, in particular made of polypropylene.

[0025] Covers 14, 16 are secured to plastic housing 12, for example by mechanical attachment. However, other possibilities are also conceivable for fastening the covers 14 , 16 on the plastic housing, for example by gluing or additional fastening elements.

[0026] The caps 14 , 16 can be made of aluminum, wherein t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com