A dust removal device in a building construction house

A dust removal device and construction technology, applied in the direction of smoke and dust removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of not being able to adsorb in multiple positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

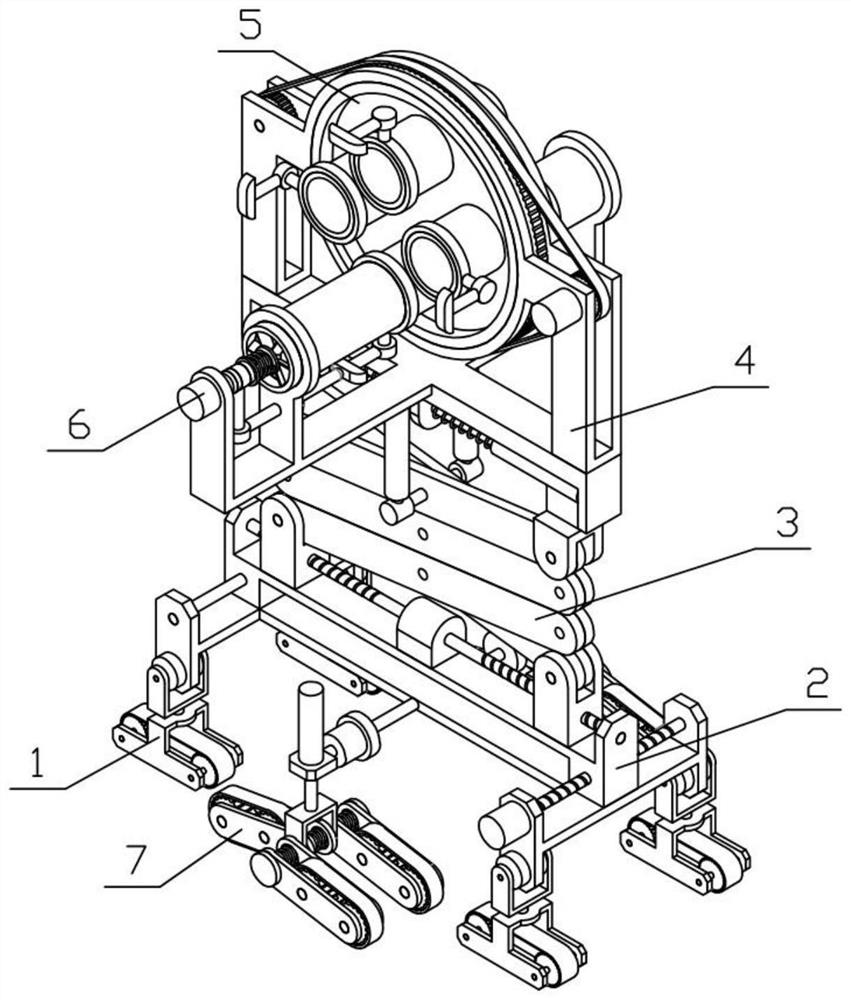

[0034] Combine below Figure 1-10Describe this embodiment, a dust removal device in a building construction room, including a moving mechanism 1, a traverse mechanism 2, a lifting mechanism 3, a dust removal support 4, a dust removal mechanism 5 and a power mechanism 6, and the movement mechanism 1 is connected with a traverse mechanism 2. The lifting mechanism 3 is connected to the traverse mechanism 2. The upper end of the lifting mechanism 3 is connected to the dust removal support 4. The dust removal support 4 is provided with the dust removal mechanism 5. The dust removal support 4 is fixedly connected to the power mechanism 6. The mechanism 6 is connected; the device can be driven by the moving mechanism 1 to move, and the traversing mechanism 2 can drive the lifting mechanism 3 to further adjust the position of the lifting mechanism 3, and the lifting mechanism 3 can adjust the horizontal height of the dust removal support 4. The moving mechanism 2 and the lifting mecha...

specific Embodiment approach 2

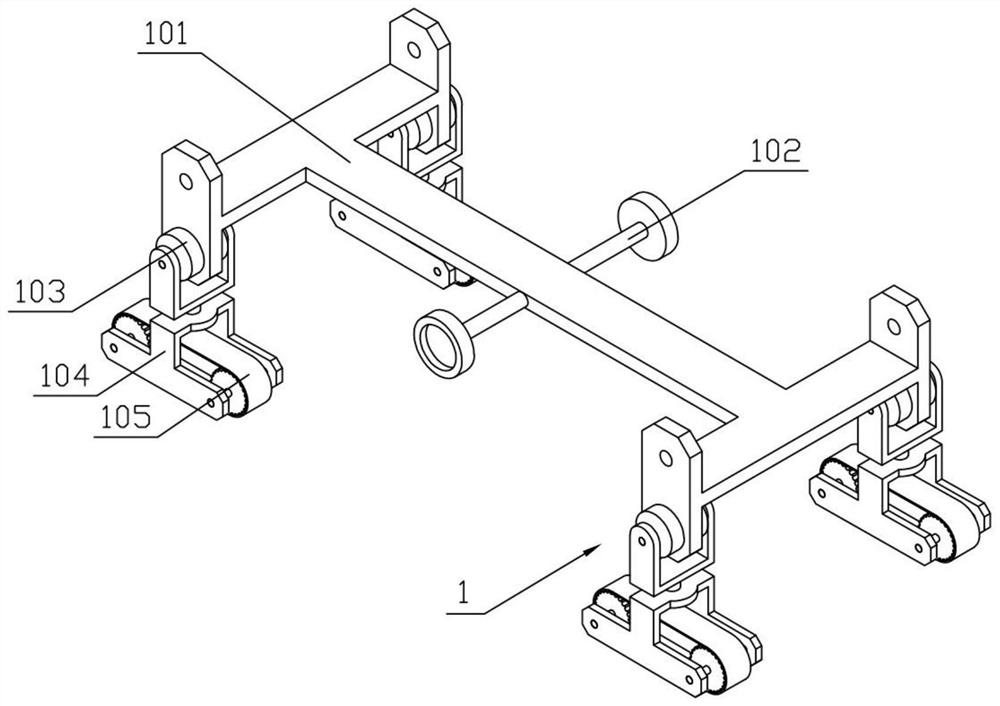

[0036] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain Embodiment 1, the moving mechanism 1 includes a moving bracket 101, a connecting column 102, a swing motor 103, a swinging bracket 104 and a crawler mechanism I 105, and the left and right sides of the middle part of the moving bracket 101 are A connecting column 102 is fixedly connected, a swing motor 103 is fixedly connected to the left and right sides of the front and rear ends of the mobile support 101, the output shafts of the two swing motors 103 are fixedly connected to a swing bracket 104, and the four swing brackets 104 are all provided with Track Mechanism I 105.

specific Embodiment approach 3

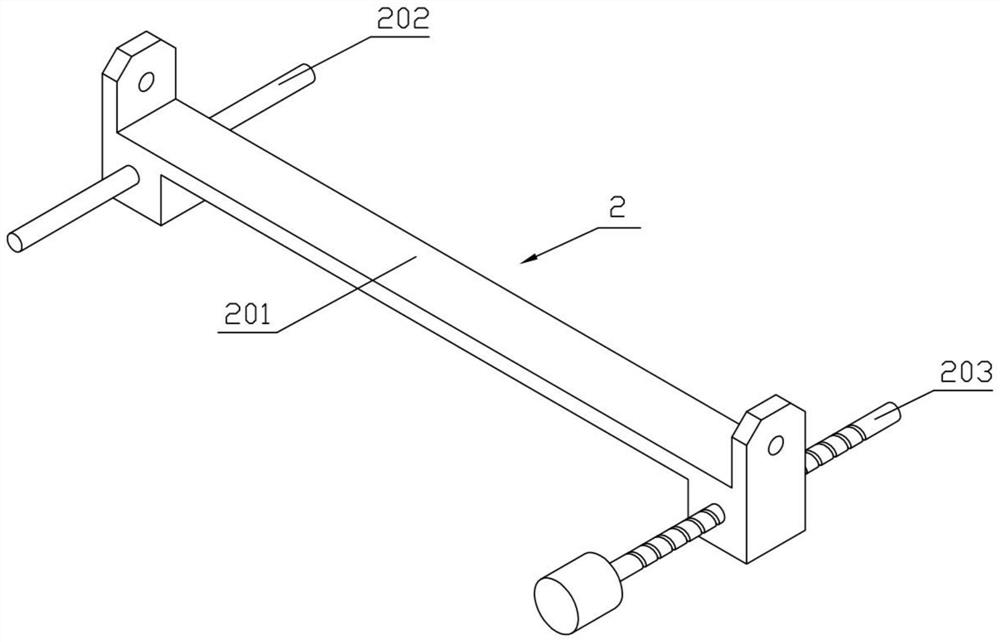

[0038] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the second embodiment, the traverse mechanism 2 includes a traverse bracket 201, a limit column 202 and a traverse motor 203, and one end of the traverse bracket 201 is slidably connected to the limit column 202 , the other end of the traversing support 201 is screwed to the output shaft of the traversing motor 203, the limit post 202 is fixedly connected to one end of the moving support 101, and the traversing motor 203 is fixedly connected to the other end of the moving support 101.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com