Soil treatment device for oil-containing waste

A waste and soil technology, applied in the restoration of polluted soil, grain treatment, and soil lifting machinery, etc., can solve problems such as pollution, and achieve the effect of increasing nutrition and increasing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

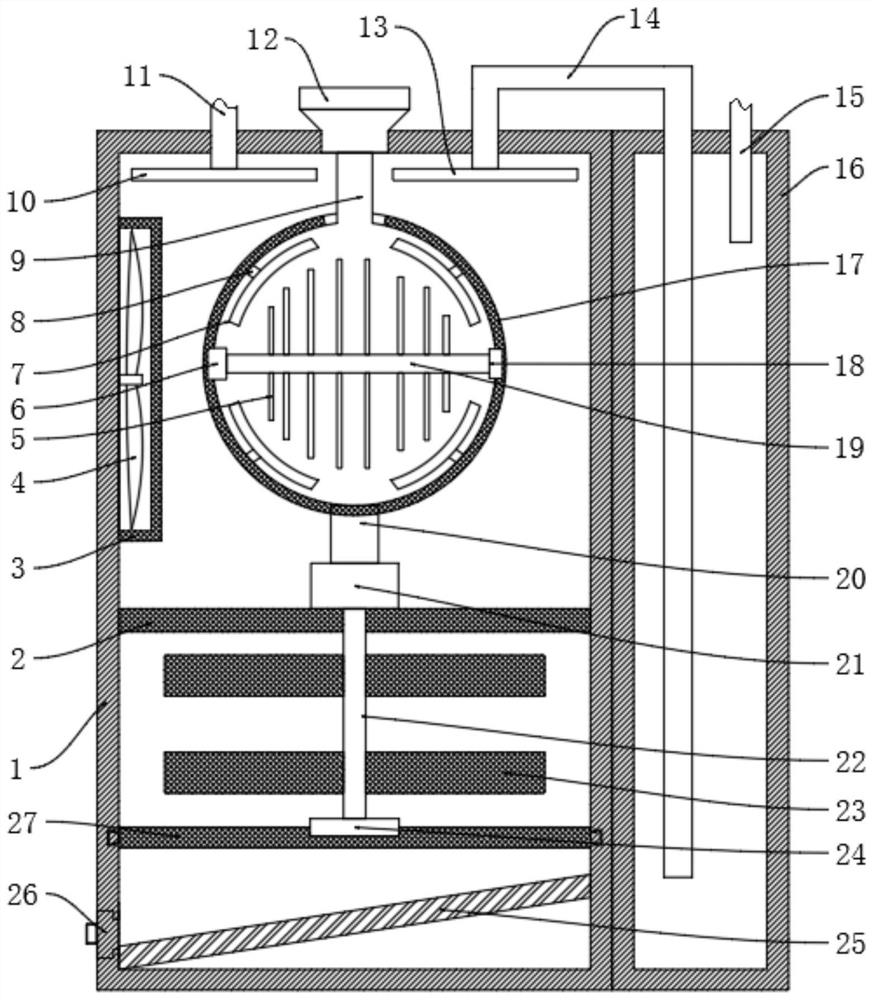

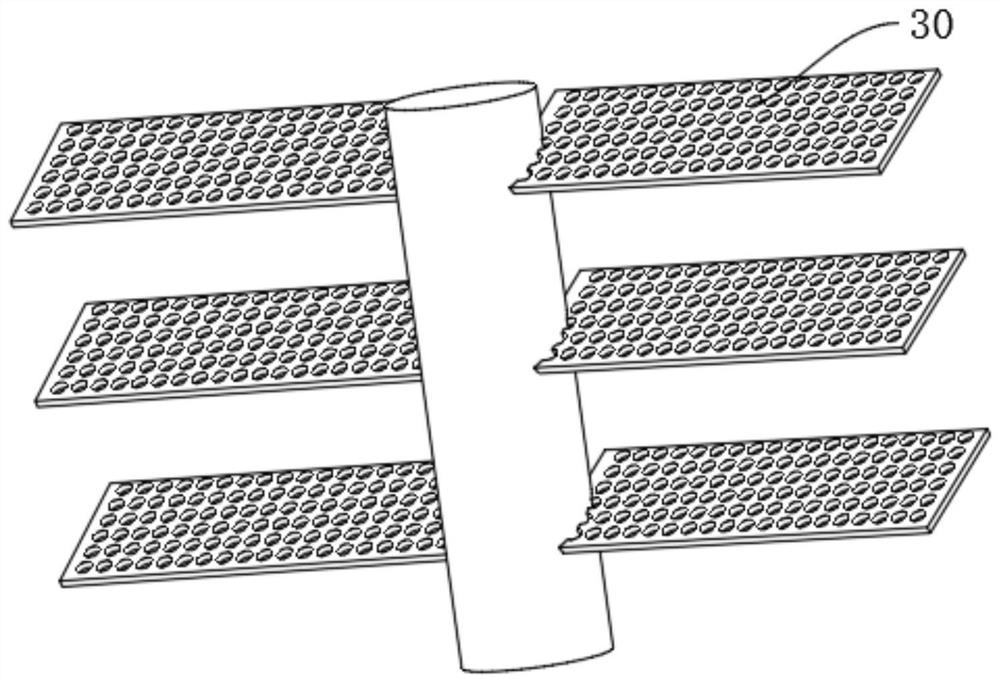

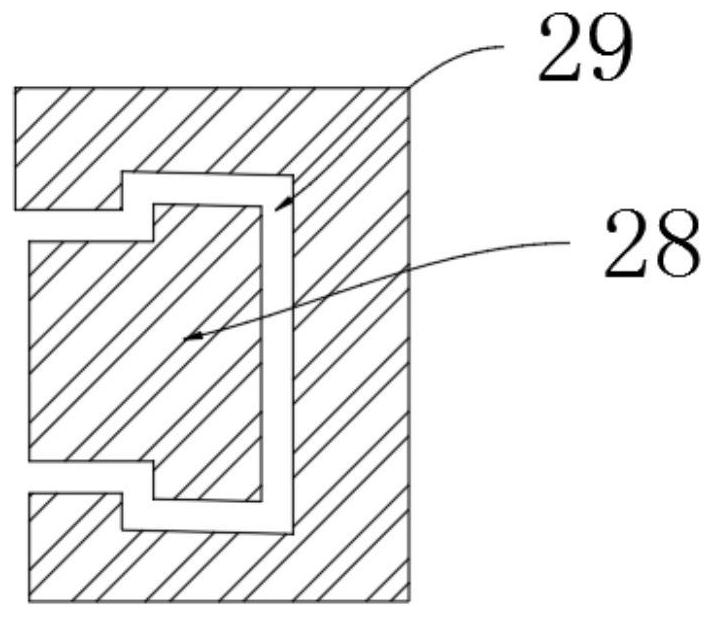

[0021] see Figure 1-4 , a soil treatment device for oily waste, comprising a treatment box 1, a soil inlet 12 and an internal processing structure, the top of the treatment box 1 is fixed with a soil inlet 12, and the inside of the treatment box 1 is provided with an internal The processing structure, the internal processing structure includes a rotating heating structure, an inlet pipe 9, a spherical screen 17, a ceramic insulation structure 8, a fixed heating plate 7, an internal crushing structure, a bidirectional motor 21 and an upper rotating shaft 20, and the soil enters The end of the port 12 is connected to the inlet pipeline 9, the inlet pipeline 9 is fixed above the spherical screen 17 through bearings, the inside of the spherical screen 17 is fixed with an internal crushing structure, and the bottom of the spherical screen 17 is fixed with an upper shaft 20, the upper shaft 20 is driven and connected by a bidirectional motor 21, the bidirectional motor 21 is fixed ...

Embodiment 2

[0028] Compared with Embodiment 1, the improvement of this embodiment is that: a top pipe 11 is fixed on the top of the processing box 1 , and a particle ejection port 10 is fixed at the end of the top pipe 11 . The nutrient granules are mixed with the soil through the granule spray outlet 10 through the top pipe 11, so that the treated soil is more nutritious.

[0029] The working principle of the present invention is: first, the soil mixed with oily waste enters the interior of the entry pipe 9 from the soil inlet 12, and then enters the interior of the spherical screen 17, and the soil is slowly heated by the fixed heating plate 7, so that the waste The oil melts slowly, and the internal motor 6 is used to drive the internal shaft 19, so that the internal fan blades 5 on the internal shaft 19 break the soil. At the same time, the two-way motor 21 drives the upper shaft 20, so that the spherical screen 17 is broken inside The crushing structure breaks the soil and rotates at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com