Concealed charging small door

An inner hidden and concealed technology, which is applied in the field of inner hidden charging small doors, can solve problems such as safety accidents and affecting visual appearance, and achieve the effects of improving safety, good appearance, and accurate opening and closing actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

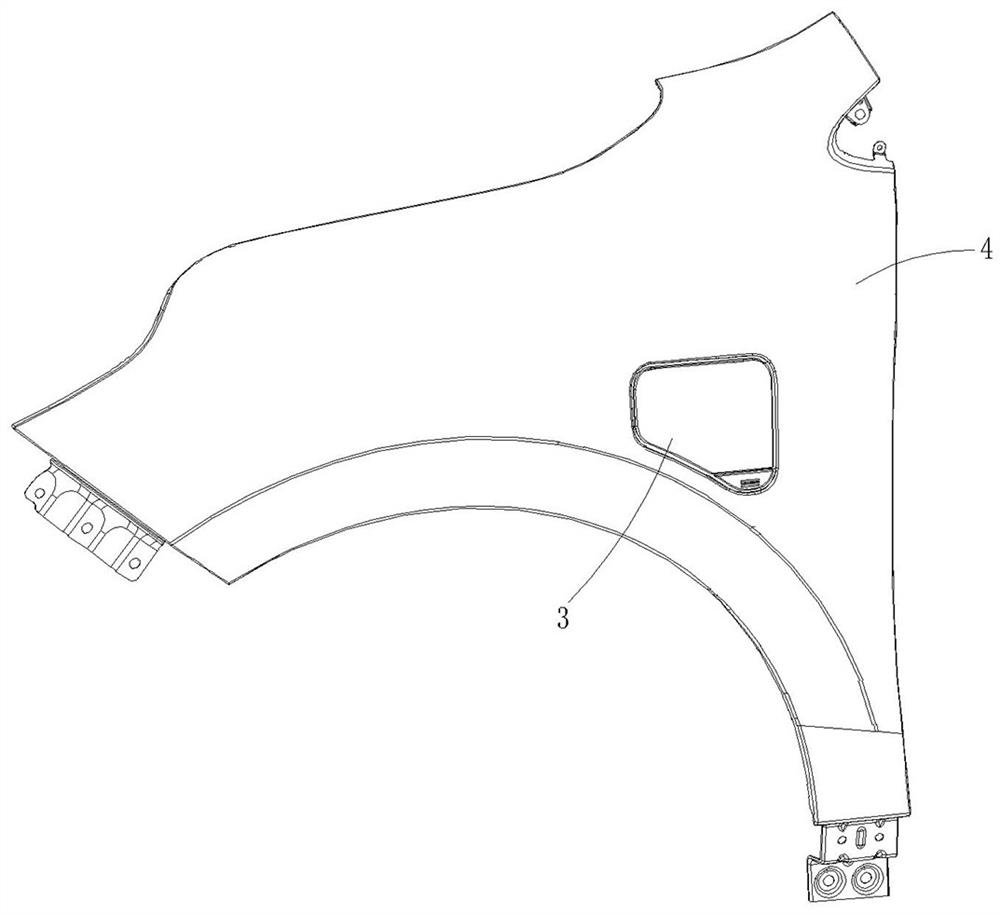

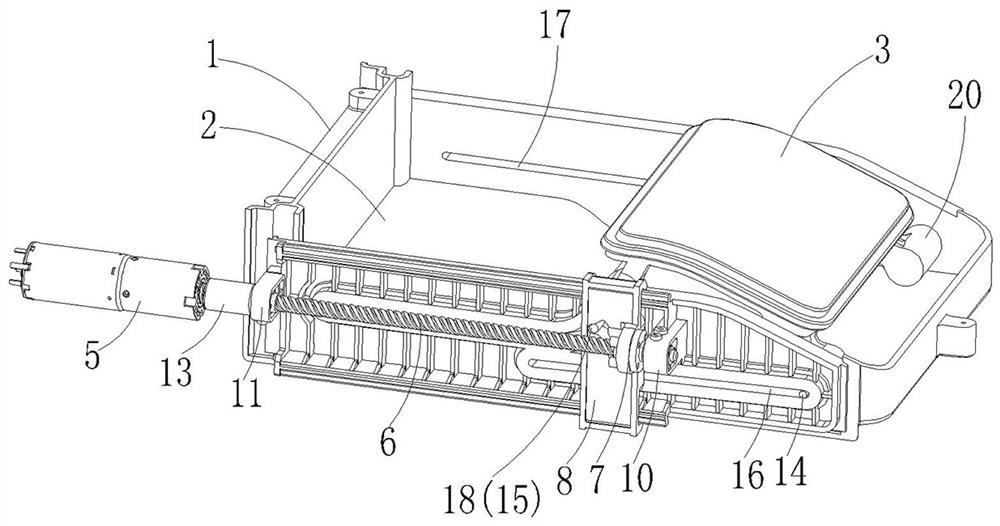

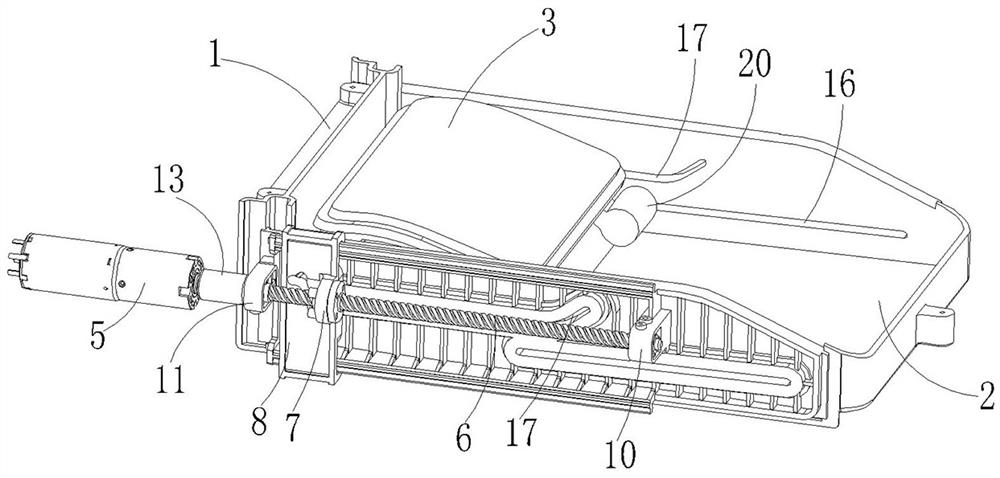

[0040] refer to Figure 1 to Figure 10 , a built-in hidden charging small door, comprising:

[0041] The charging port seat 1 has an inner cavity 2, an external opening 29 communicating with the inner cavity 2, and a charging interface respectively communicating with the inner cavity 2 and the battery assembly in the vehicle, and the charging port seat 1 is also provided with a guide track groove;

[0042] The charging port cover 3 is installed in the charging port seat 1 in an openable and closable manner, and has at least a closed state and an open and hidden state. The charging port cover 3 is provided with a sliding foot assembly, and the sliding foot assembly is slid In the guide track groove;

[0043] The driving mechanism 5 is used to provide power to switch the charging port cover 3 between the closed state and the open and hidden state;

[0044] Lead screw slider transmission assembly, which includes a lead screw 6, a nut seat 7 and a guide slider 8 connected in seq...

Embodiment 2

[0053] refer to Figure 11 The difference between the present embodiment and the first embodiment is only that: the upper and lower ends of the guide slider 8 are provided with a connecting portion 26 protruding inward, and the connecting portion 26 is provided with a slideway groove 27, so The upper and lower ends of the outer wall of the charging port seat 1 are provided with guide sliders 28, and the guide sliders 28 are embedded in the slideway grooves 27, so that the guide slider 8 can move along the The guide slide bar 28 slides back and forth. Adopting the structural arrangement of this embodiment, a more reliable cooperative relationship is formed between the guide slider 8 and the charging port cover 3, and the sliding operation of the guide slider 8 is more stable and reliable, and no jamming or derailment occurs .

[0054] When the present invention is applied in the automobile, its working principle is as follows:

[0055] When the charging port cover 3 needs to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com