Efficient energy-saving aluminum-clad copper steam generator

A steam generator, a high-efficiency and energy-saving technology, applied in the directions of steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of high energy consumption, high cost, large heat emission, etc., and achieve low heat emission and long service life. , the effect of low heat emission to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

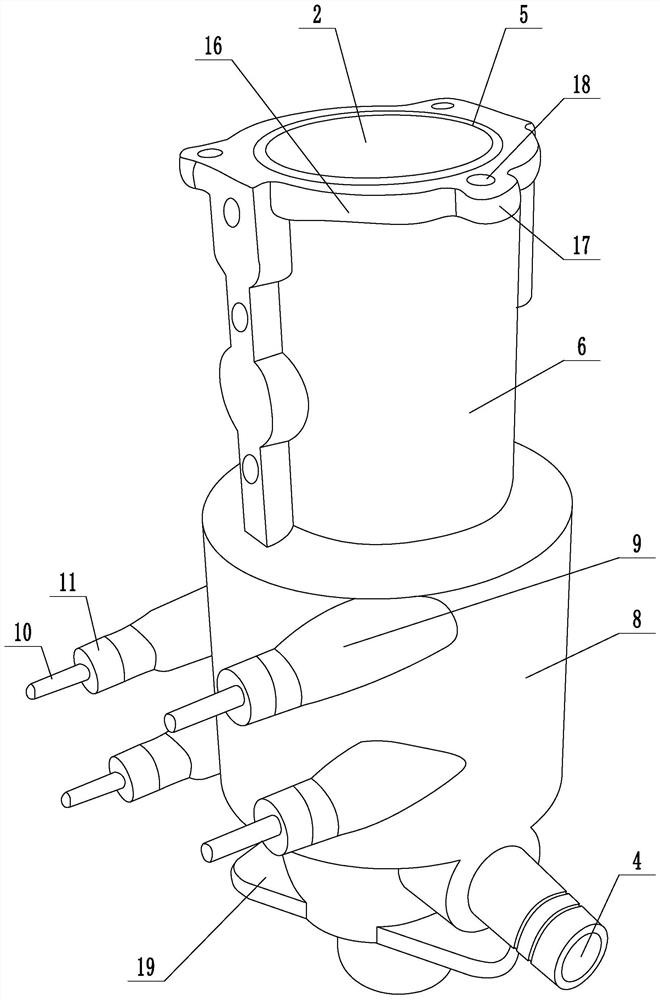

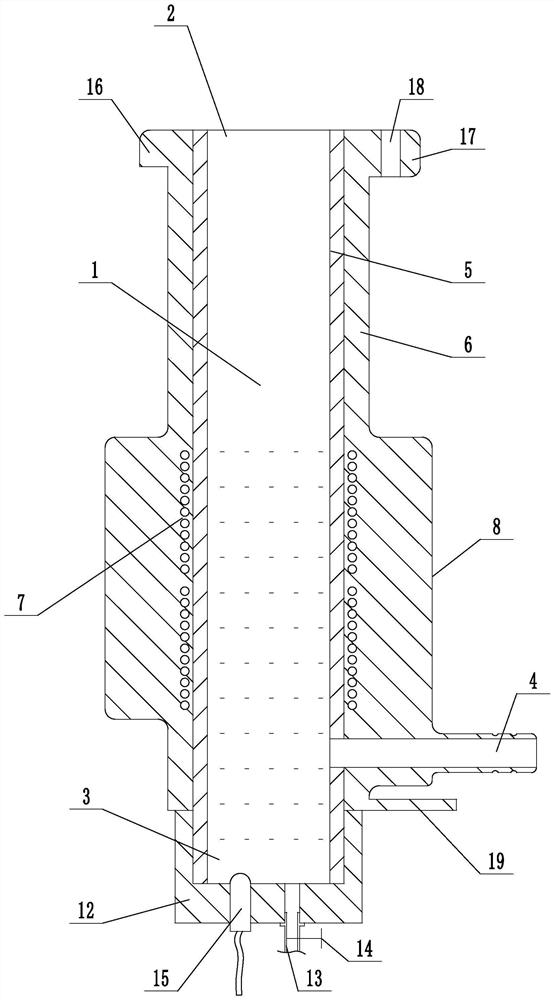

[0021] Embodiment 1: A high-efficiency energy-saving aluminum-clad copper steam generator (see attached figure 1 , attached figure 2 ), including the steam generator body, the steam generator body is provided with a heating chamber 1, the upper end of the steam generator body is provided with a steam outlet 2, the lower end of the steam generator body is provided with a sewage outlet 3, and the steam generator body is provided with a heating chamber The water inlet nozzle 4 connected to the cavity, the steam generator body includes a copper inner sleeve 5, an aluminum outer jacket 6 wrapped outside the copper inner sleeve, and a heating wire 7 is installed between the copper inner sleeve and the aluminum outer jacket. The heating chamber is placed in a copper inner sleeve. A heat-insulating protruding ring 8 is provided on the outer wall of the aluminum jacket corresponding to the heating wire. The two ends of the heating wire extend out of the outer wall of the aluminum ja...

Embodiment 2

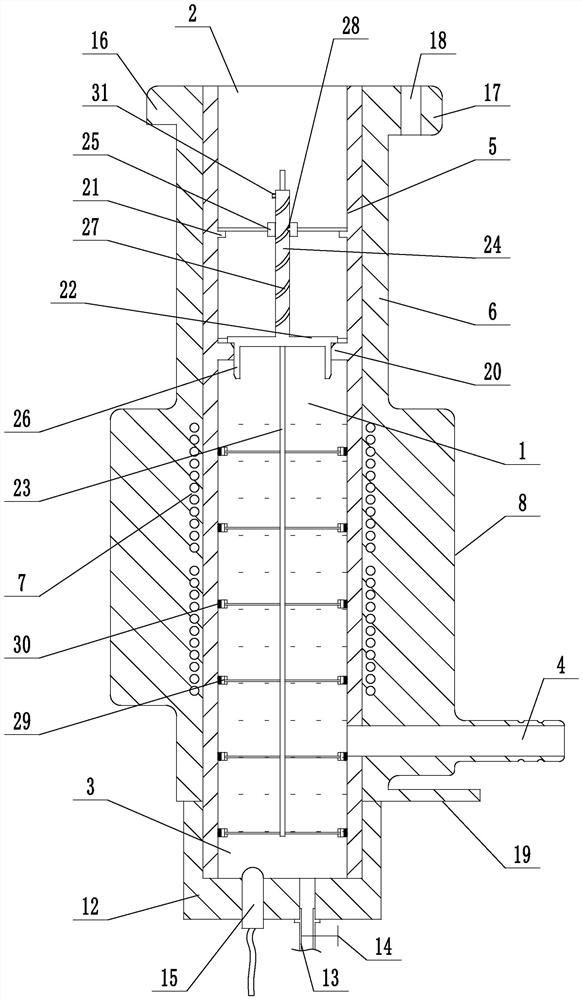

[0025] Embodiment 2: A high-efficiency energy-saving aluminum-clad copper steam generator (see attached image 3 ), its structure is similar to that of Embodiment 1, the main difference is that in this embodiment, the inner wall of the copper inner sleeve is provided with a supporting convex ring 20 and a connecting block 21, the connecting block is placed above the supporting convex ring, and the supporting convex ring is placed on the electric heater Above the wire, a descaling mechanism is installed in the copper inner sleeve. The descaling mechanism includes a driving cover 22, a connecting rod 23, a rotating rod 24, and a positioning sleeve 25. The driving cover is supported on the supporting convex ring. The extension ring 26 that extends down, the extension ring fits in the supporting convex ring, the connecting rod and the rotating rod are all connected with the driving cover, the positioning sleeve is tightly connected with the connecting block, the outer wall of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com