wood edger

A kind of edge grinding machine and wood technology, which is applied in the direction of grinding frame, machine tools suitable for grinding the edge of workpieces, and parts of grinding machine tools, etc. to avoid re-pollution, keep the bristles clean, and increase the number of vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

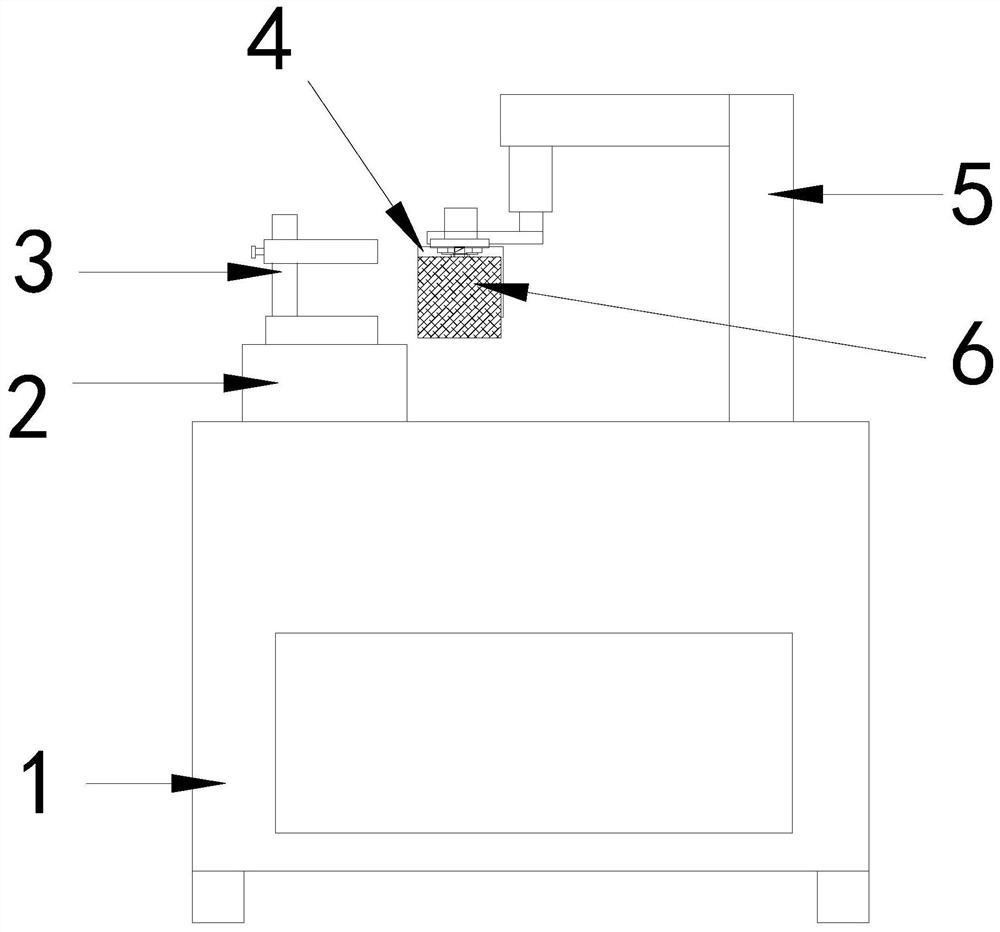

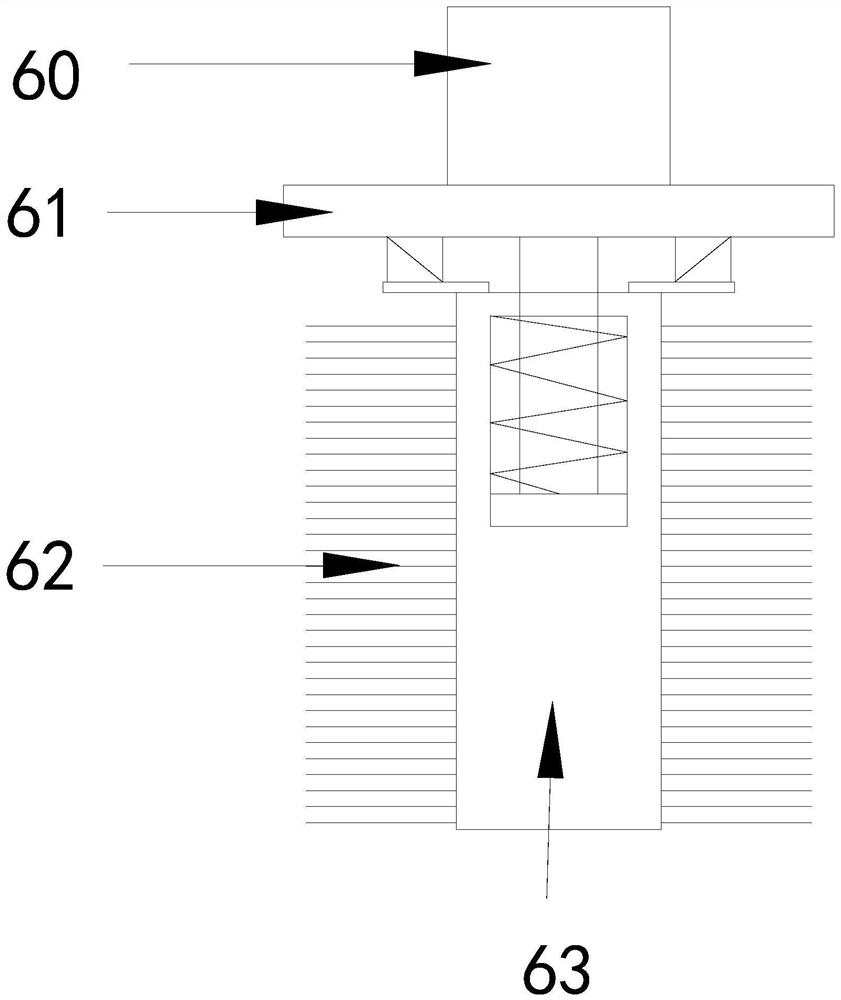

[0028] See Figure 1-2 The present invention provides a lumber edger aspect: the structure includes a base 1, rail 2, the jig 3, wheel 4, the support frame 5, the cleaning device 6, the top of the support frame 5 is connected with the base 1, the wheel 4 is mounted on the support frame 5, and the cleaning device 6 is connected to the support frame 5, the rail 2 is connected to the base 1, the guide rail is mounted on the jig 23, respectively, on both sides of the grindstone 4 6 is provided with cleaning means, the cleaning device 6 comprises a motor 60, a support plate 61, the bristles 62, the shaft 63, the shaft 63 is provided with an outer side surface of the bristle 62, the shaft 63 is connected to the top of the motor 60, the motor 60 connected to the support plate 61, the support plate 61 and the support frame 5 is connected.

[0029] Working principle: In use, the timber 3 is fixed to the jig, to be polished by a grindstone rapidly rotating timber 4, by a clamp 3 moves in the...

Embodiment 2

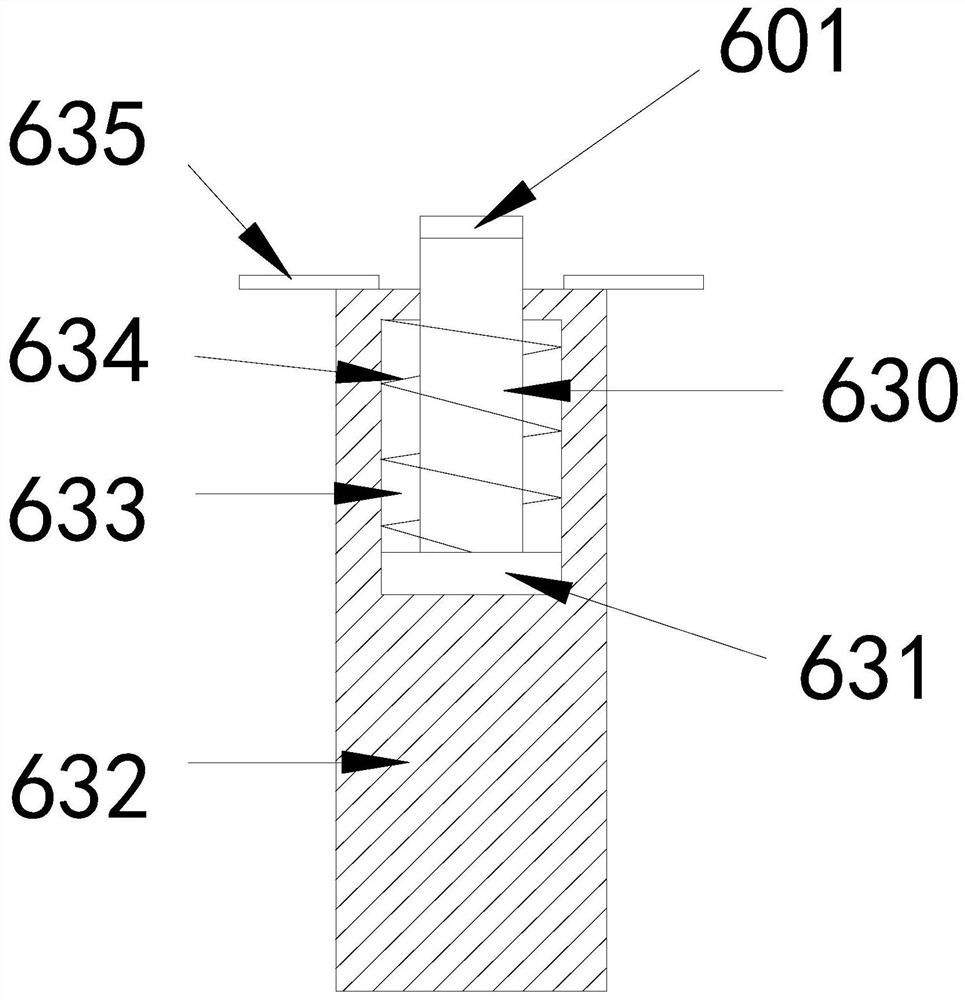

[0031] See Figure 1-6 The present invention provides a lumber edger aspect: the structure includes a base 1, rail 2, the jig 3, wheel 4, the support frame 5, the cleaning device 6, the top of the support frame 5 is connected with the base 1, the wheel 4 is mounted on the support frame 5, and the cleaning device 6 is connected to the support frame 5, the rail 2 is connected to the base 1, the guide rail is mounted on the jig 23, respectively, on both sides of the grindstone 4 6 is provided with cleaning means, the cleaning device 6 comprises a motor 60, a support plate 61, the bristles 62, the shaft 63, the shaft 63 is provided with an outer side surface of the bristle 62, the shaft 63 is connected to the top of the motor 60, the motor 60 connected to the support plate 61, the support plate 61 is connected to the support frame 5, the shaft 63 includes a connecting rod 630, a spring seat 631, the lift cylinder 632, cavity 633 activity, lifting the spring 634, the struts 635, the lif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap