Automobile, powertrain suspension system and its torsion tie rod

A technology of torsion-resistant tie rods and piston rods, which is applied to power plants, vehicle components, jet propulsion devices, etc., can solve the problems of low peak damping and inability to isolate powertrain vibrations well, so as to improve vibration isolation capability and low Effects of dynamic stiffness and damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention discloses an anti-rod to achieve the stiffness and damping of the anti-rod rod. Further, the present invention also discloses a power assembly suspension system and a car having the above anti-tolerance rod.

[0048] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

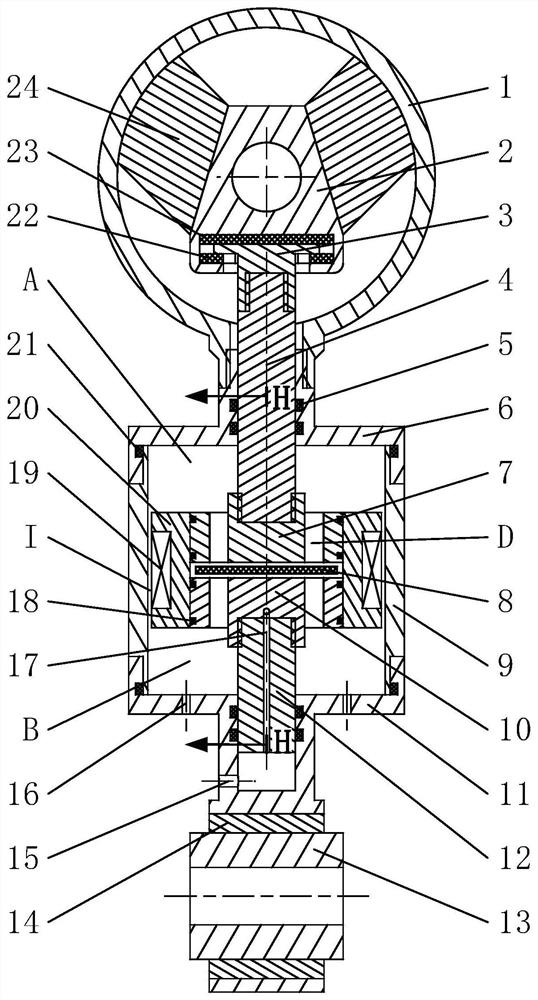

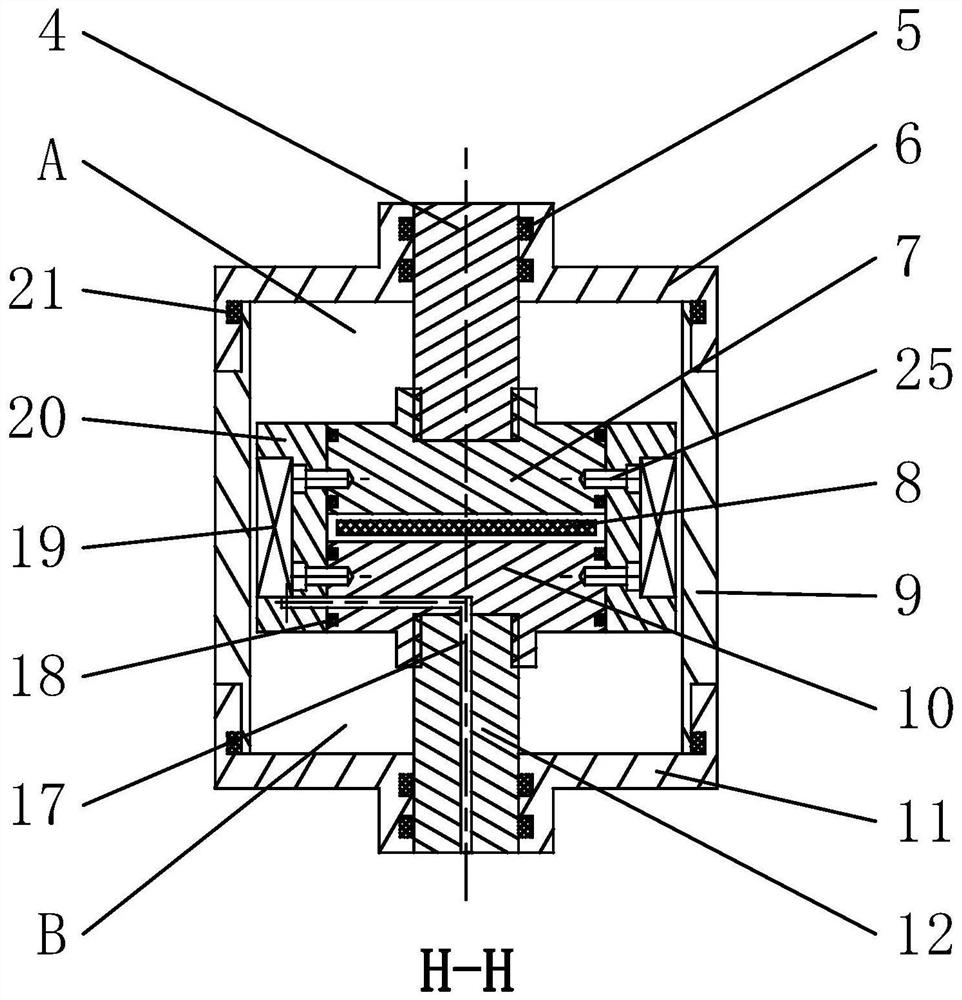

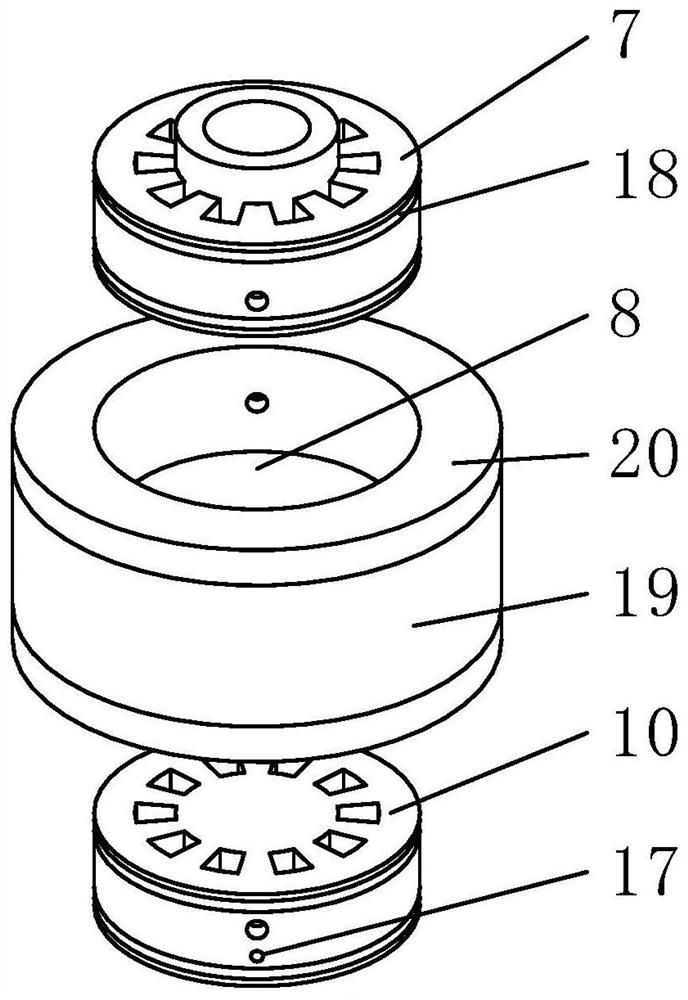

[0049] Such as Figure 1 - Figure 8As shown, the present application also discloses an anti-tolert rod comprising a rubber unit and a hydraulic unit, wherein the rubber unit comprises a rerouese end 2 and an elastic rubber reing 24 for connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com