Forced oil circulation transformer oil-submerged pump fault monitoring device and monitoring method

A forced oil circulation and fault monitoring technology, which is applied in the field of forced oil circulation transformer submersible pump fault monitoring device, can solve the problems of continuous fault development, complex judgment process, slow judgment speed, etc., achieve good social and economic benefits, and reduce judgment time The effect of high length and monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

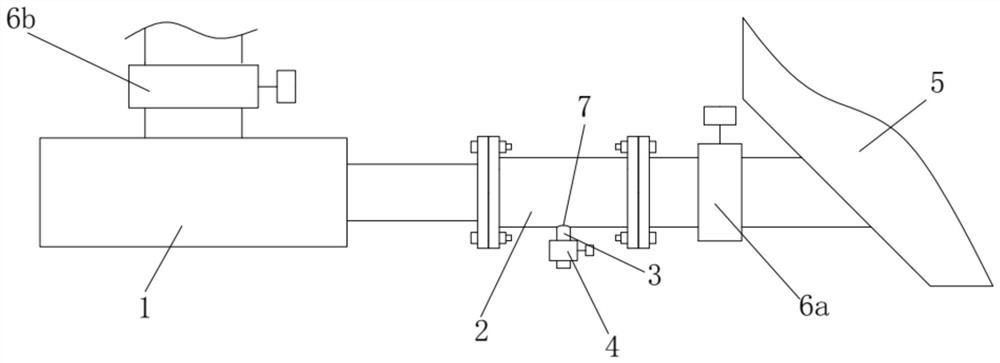

[0020] Depend on Figure 1-3 Given, a kind of forced oil circulation transformer submersible pump failure monitoring device of the present invention comprises main transformer 5 and submersible pump 1, and the oil outlet of submersible pump is connected with the oil inlet of main transformer 5 through oil pipeline 2, and described oil pipeline 2 is provided with a sampling port 7 for collecting oil samples, a submersible pump outlet valve 6a is provided on the pipeline between the sampling port and the main transformer 5, and a submersible pump inlet valve 6b is provided on the pipeline connected to the inlet of the submersible pump 1. The monitoring device also includes a transformer oil chromatography tester for detecting the total hydrocarbon content of dissolved gas in the oil sample taken from the sampling port.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com