Self-locking and anti-loosening sealing method of sealing bolt and self-locking and anti-loosening sealing bolt

A technology for sealing bolts and anti-loosening, which is applied to bolts, engine seals, screws, etc., which can solve problems such as unsatisfactory sealing effects, potential safety hazards, and reduced sealing effects, so as to improve convenience, ensure sealing effects, and prevent bolts from loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

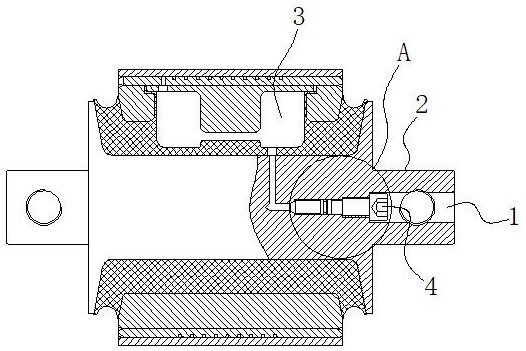

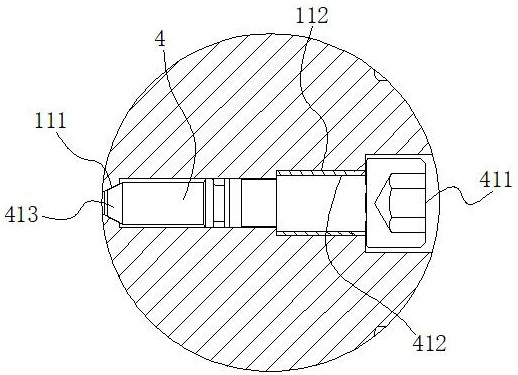

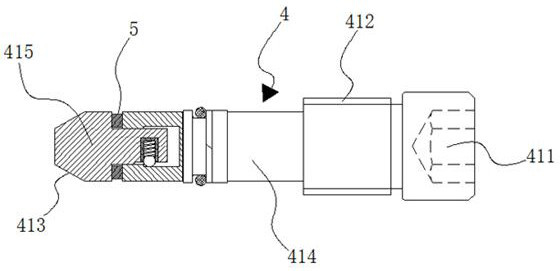

[0035] Example: such as Figure 3 to Figure 5 Shown is a self-locking and anti-loosening sealing method for sealing bolts, which is to set the bolts 4 into separate parts, and install a gasket 5 between the split bolts 4, and the gasket is located between the external thread 412 of the bolt and the cone of the bolt. The positions between the type tops 413 are achieved by screwing the split bolts into the liquid injection hole 1 to achieve a self-locking and anti-loosening seal. Through structural design, this embodiment cleverly adds gaskets on the basis of ensuring that the original sealing effect can be achieved, thereby preventing the occurrence of bolt looseness and ensuring good sealing performance during daily work, thereby eliminating the need for safety. Hidden danger.

[0036] The split bolt 4 includes a tail bolt body 414 and a top bolt body 415, the gasket 5 is set between the tail bolt body 414 and the top bolt body 415, and the nut part 411 is arranged on one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com