A readable measurement method for blade profile

A measurement method and blade technology, applied in the direction of mechanical counter/curvature measurement, measuring device, mechanical measuring device, etc., can solve the problems of low accuracy of multiple detection data of the blade profile, and the detection data cannot be obtained intuitively, so as to reduce the The effect of equipment maintenance cost, reduction of clamping time and improvement of data accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

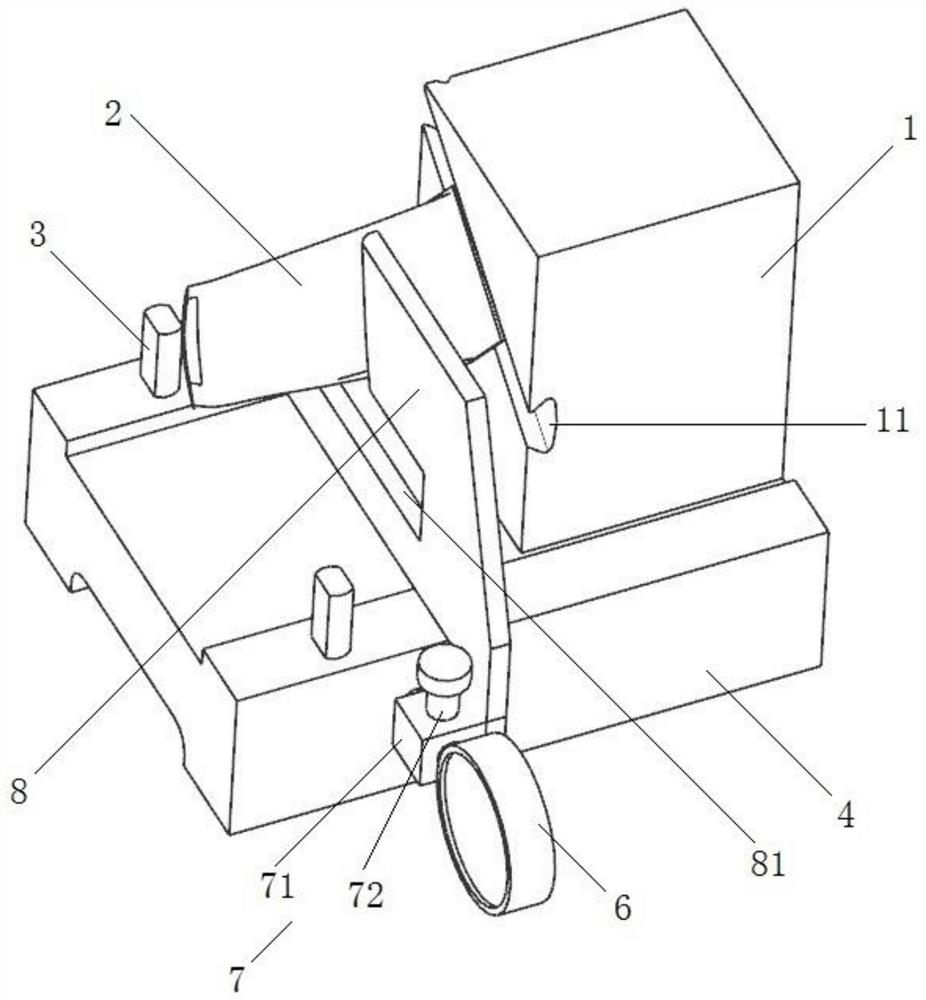

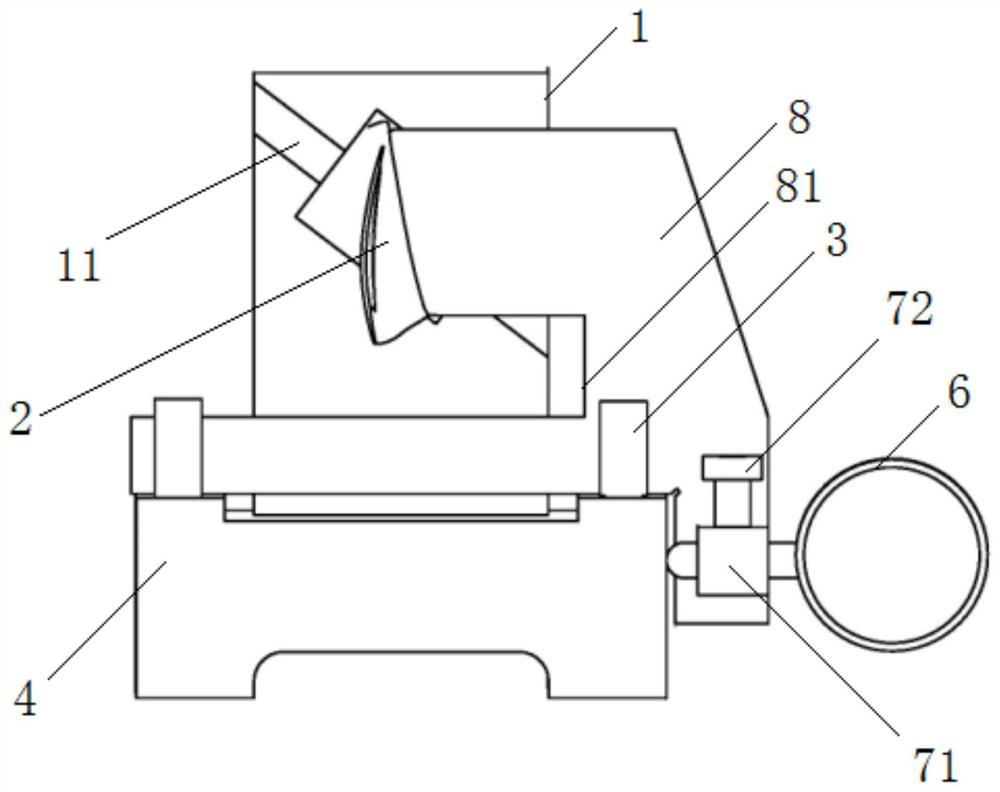

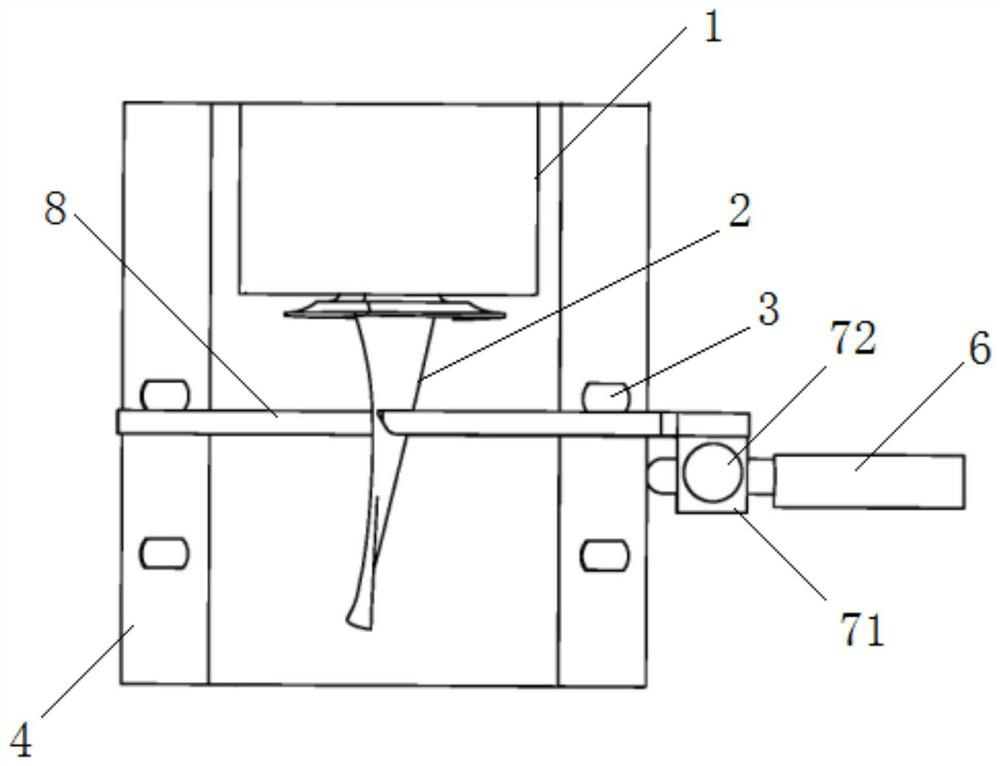

[0032] see Figure 1 to Figure 4 shown.

[0033] A measuring tool with readable blade profiles according to the present invention comprises: a base 4, a chuck 1 fixed on the top plane of the base 4, the front side of the chuck 1 is provided with a mounting groove 11 inclined to the top surface of the base 4, The root of the blade 2 is tightly clamped with the installation groove 11. When the front top side end surface of the profile template 8 is in contact with the profile line of the blade 2, the contact force between the profile template 8 and the blade 2 is horizontal, and the inclined installation groove 11 restricting the movement of the root of the blade 2 in the horizontal direction;

[0034] Section positioning pins 3, a plurality of section positioning pins 3 are fixed on both sides of the top surface of the base 4 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com