A kind of forging process method of tc18 titanium alloy large-scale bundled bearing forgings

A technology of TC18 and process method, which is applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. It can solve the problems of high design index requirements, difficulty in ensuring the uniformity of bar structure, and large deformation resistance in the two-phase area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Taking the heavy-duty launch vehicle TC18 bundled support forging product as an example, the size specification is 1210mm×1260mm×550mm.

[0045] Step (1): Multi-fire forging billet

[0046] (1) Ingot billet forging: place a TC18 titanium alloy round ingot with a size of Φ650×1500mm in a high-temperature electric furnace and heat it to 1100-1200°C, and after a certain period of time, carry out upsetting and elongation deformation on a forging press The amount of single upsetting and elongating deformation is controlled at 40% to 50%;

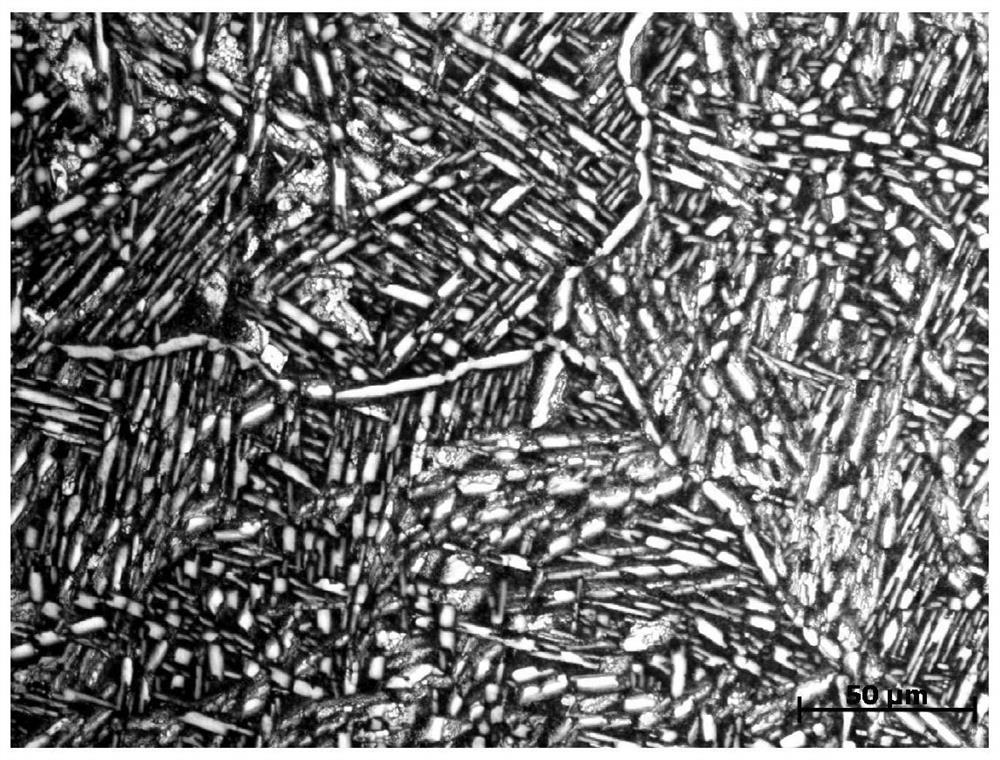

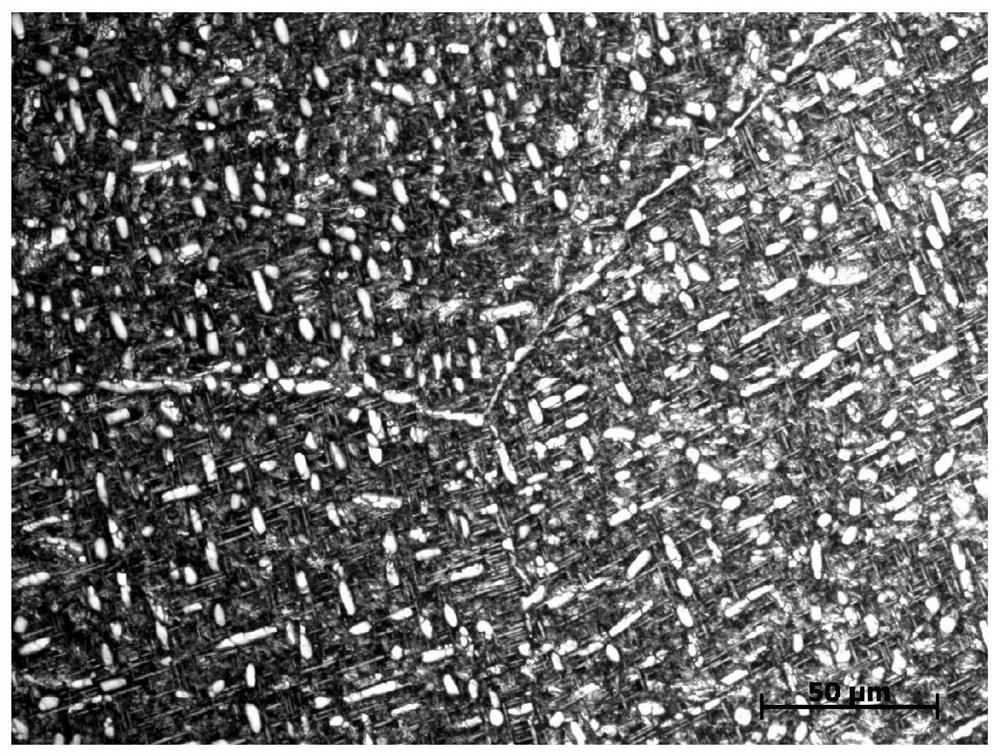

[0047] (2) Multi-fire reversing upsetting deformation: The phase transition point of the ingot is measured to be 860°C. Alternate multi-fire reversing upsetting deformation is carried out above the phase transition point and below the phase transition point. The initial forging temperature of the billet heating temperature for phase zone forging is controlled at 900-1100°C, and the initial forging temperature of two-phase zone forging bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com