Forging method of high-boss TC18 titanium alloy die forging

A TC18, high boss technology, applied in the field of forging hot processing, to reduce the difficulty of die forging, solve the problem of small deformation, and reduce the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Die forging of a certain type of machine pillar outer cylinder, the material is TC18, the outline size of the forging is 927×385×279, the weight on one side is 8-10mm, and the maximum projected area is 0.231m 2 . The pre-forging design method of this patent comprises the following steps:

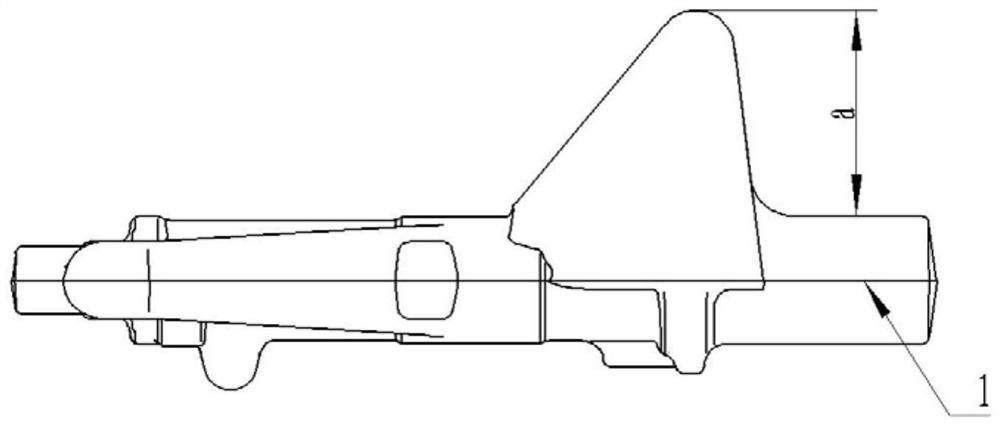

[0044] Step 1: Design the final forging according to the part shape (see figure 1 ), the maximum projected area of the final forging is 0.231m 2 It is the parting surface, which is convenient for the final forging forming;

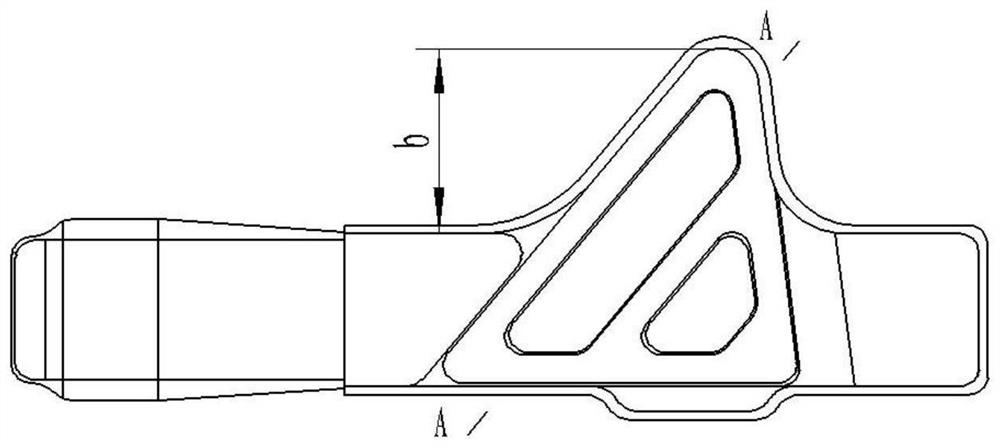

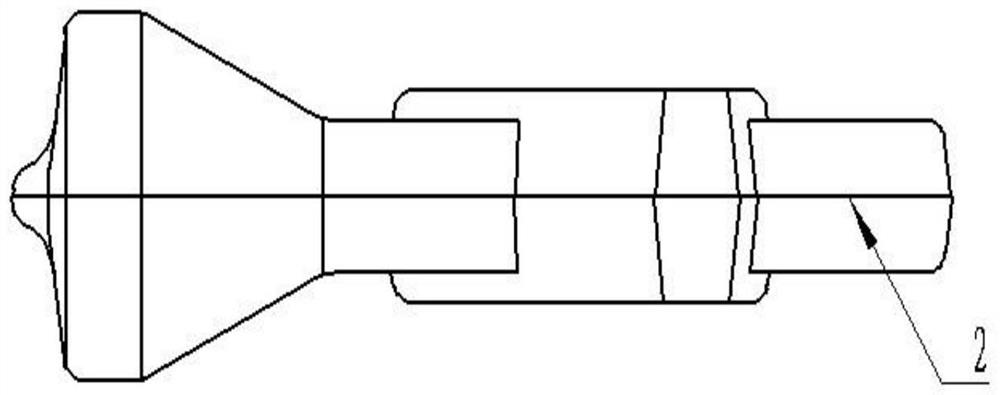

[0045] Step 2: Design the simplified pre-forging according to the structure of the final forging (see figure 2 ), the parting surface of the pre-forging is chosen to be perpendicular to the parting surface of the final forging (see image 3 ), when die forging is formed, pre-forging and final forging are cross forging methods; grooves are dug on the upper and lower surfaces of the pre-forging (see Figure 5 ), where U-shaped groove L=80mm, h=20mm; satisfy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com