Welding fume purification and dust removal device used in tank body

A welding fume purification and dust removal device technology, applied in the direction of dust removal, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of dust accumulation in the tank, affecting the health of workers, and smoke and dust cannot be discharged, so as to avoid danger Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and some embodiments.

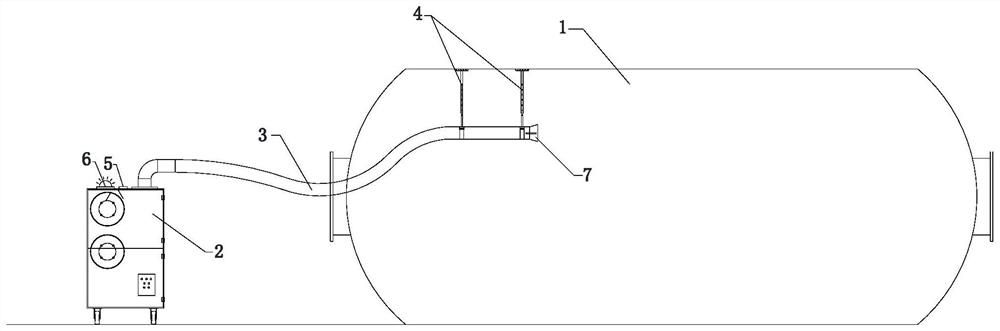

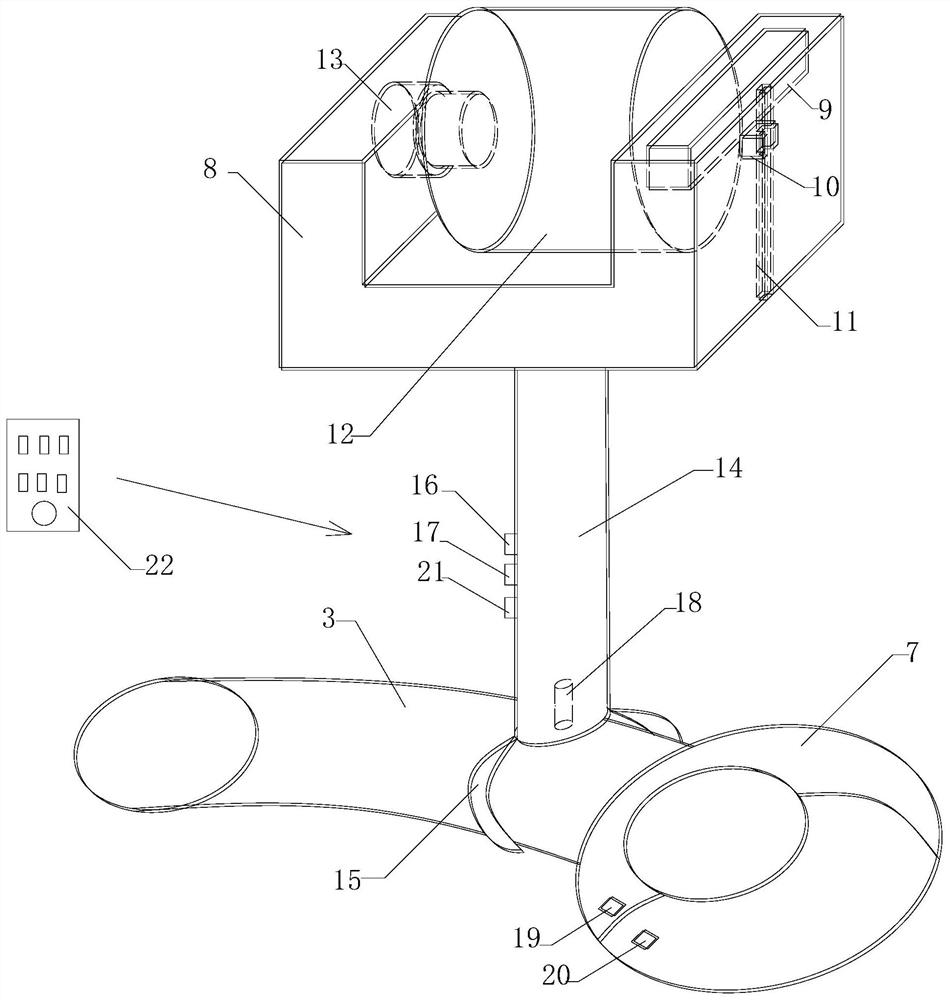

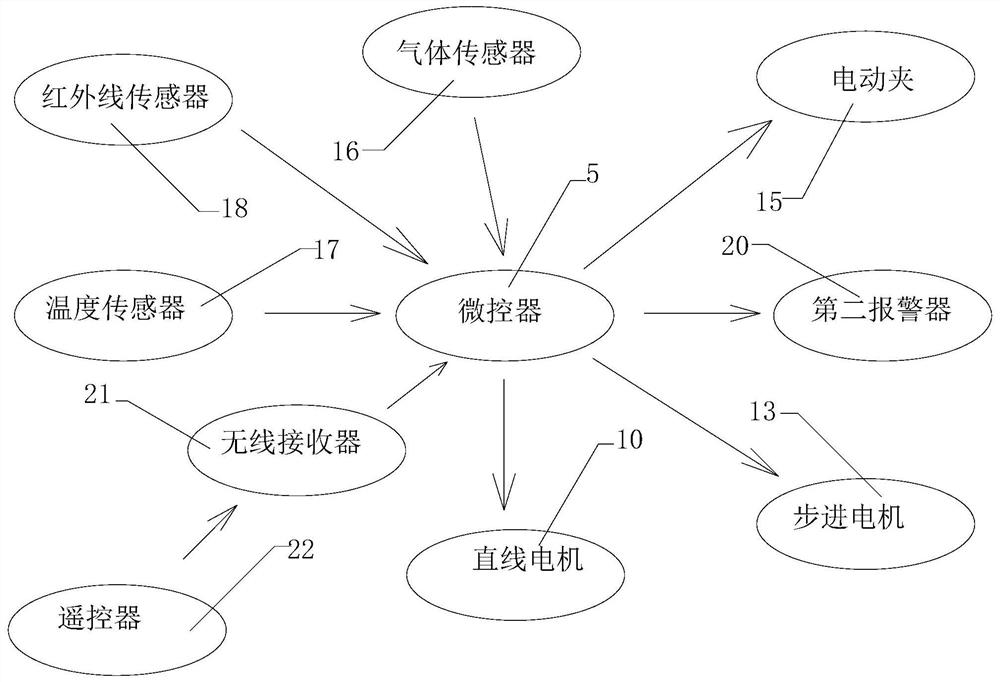

[0017] Figure 1-3 Among them, a welding fume purification and dedusting device used inside the tank body, including a filter cartridge dust collector 2, a telescopic hose 3, a gas collection hood 7, and a plurality of devices that can fix the telescopic hose 3 inside the tank body 1 and move it. A fixing device 4, one end of the telescopic hose 3 is connected with the cartridge type dust collector 2, and the other end is connected with the gas collecting hood 7, which can extend into the inside of the tank body 1, and is hung and fixed at one end of the fixing device 4, so that the gas collecting hood can be 7 corresponds to the internal welding point of the tank body 1, and the other end of the fixing device 4 can be fixed to the inner wall of the tank body 1; The base, the electric telescopic rod 14 for adjusting the position of the gas collecting hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com