Copper oxide nanowire loaded silver particle composite electrode, preparation method and application

A copper oxide nanowire and composite electrode technology, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of low carbon dioxide reduction catalytic efficiency, few catalytic active sites, and large specific surface area. The effect of increasing catalytic reaction active sites, good application prospects, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The composite electrode in this embodiment, the preparation method thereof includes the steps of:

[0077] As a substrate as a substrate, it is soaked in acetone, and the ultrasonic treatment is transferred for 10 min; then transfer the substrate to 3 mol L. - 1 In the HCl, ultrasonic treatment is 10 min; deionized water is rinsed several times, dry under the flow of nitrogen, resulting in U.

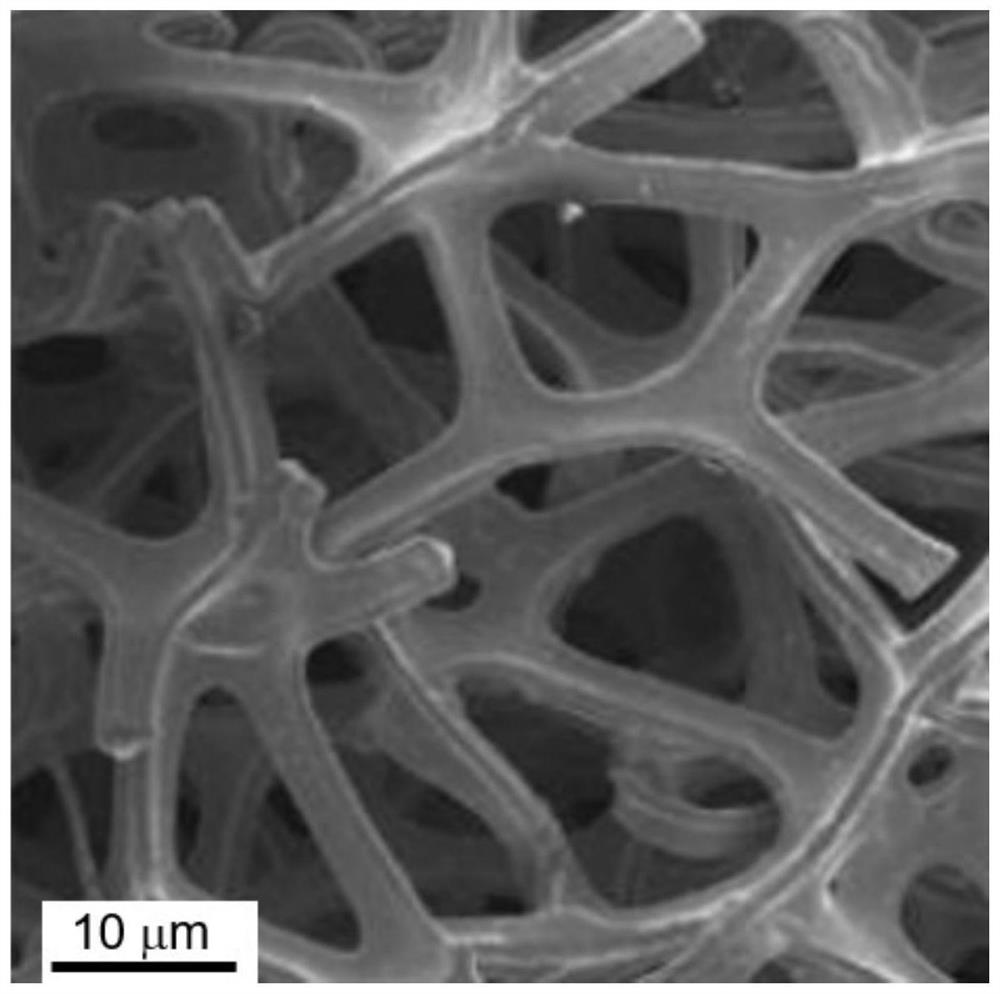

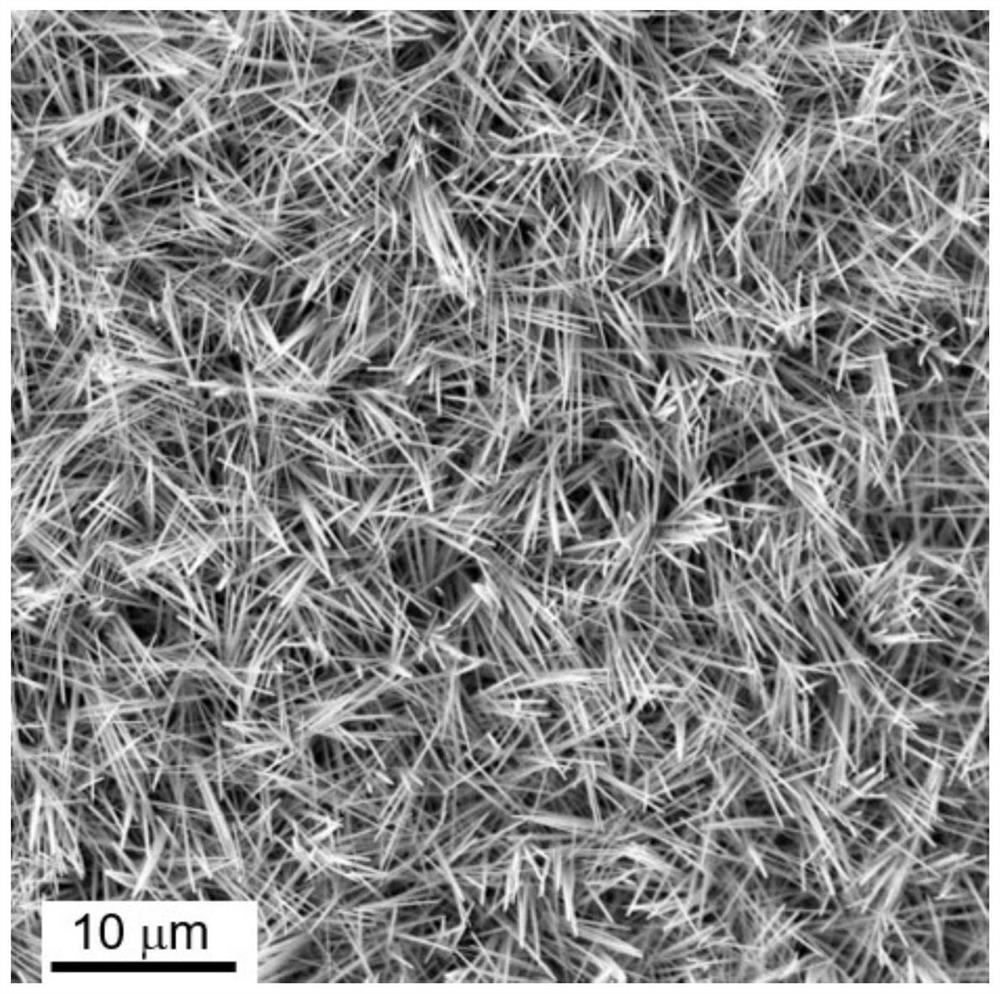

[0078] 3 g of NaOH was dissolved in 30 ml of deionized water, followed by adding 0.86g (NH) 4 ) 2 S 2 O 8 , Stirred for 10 min, resulting in V; extracting U for 20min, rinse with deionized water, drying under the flow of nitrogen, to obtain W; add W into the porcelain, 5 ° C · min -1 After an annealing at 150 ° C for 2 hours, X (cuo nanowire) is obtained; the foam copper scan electron microscope is figure 1 The scanning electron microscopy of X (Cuo Nano) is like figure 2 Indicated.

[0079] Take 45ml 5mmol L -1 Agno 3 Mix Y is mixed with 5 ml of anhydrous methanol to be immersed in...

Embodiment 2

[0086] The composite electrode in this embodiment, the preparation method thereof includes the steps of:

[0087] Use copper foil as a substrate, soak it in acetone, ultrasonic treatment 10 min; transfer the substrate to 3 mol·L -1 In the HCl, ultrasonic treatment is 10 min; deionized water is rinsed several times, dry under the flow of nitrogen, resulting in U.

[0088] 3 g of NaOH was dissolved in 30 ml of deionized water, followed by adding 0.86g (NH) 4 ) 2 S2 O 8 , Stirred for 10min, to give V; V dipped in the solution in the U 20min, rinsed with deionized water several times, dried under a stream of nitrogen to give W is;

[0089] W into the boat and the porcelain in air at 5 ℃ min -1 , Annealing at 150 deg.] C 2h, cooled to obtain X-; take 45mL10mmol L -1 Agno 3 5mL anhydrous methanol and mixed uniformly to obtain the Y;

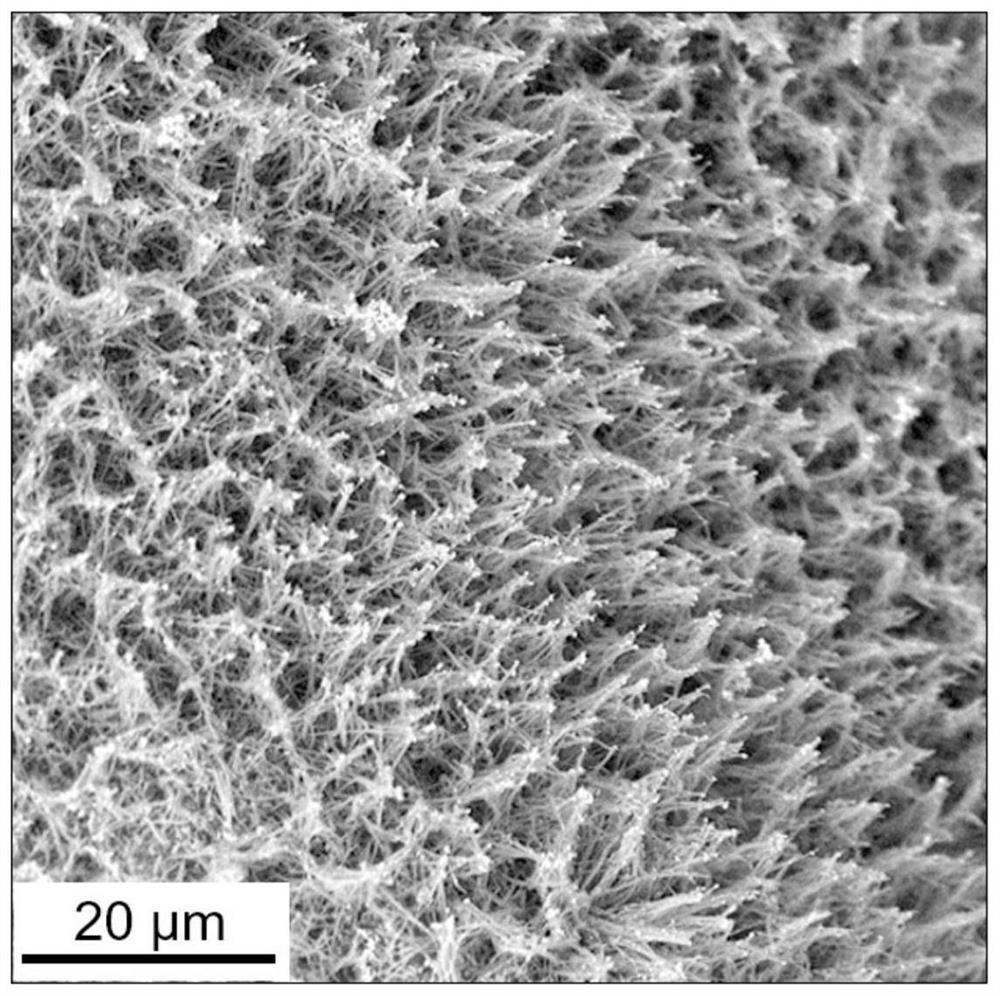

[0090] X-Y is immersed in the solution, the generator side light irradiation xenon lamp catalytic X, taken deionized water rinse 2min electrode several ti...

Embodiment 3

[0097] The composite electrode in this embodiment, the preparation method thereof includes the steps of:

[0098] Copper foil as the substrate, immersed in acetone and sonicated for 10min; the substrate was transferred to 3mol L -1 In the HCl, ultrasonic treatment is 10 min; deionized water is rinsed several times, dry under the flow of nitrogen, resulting in U.

[0099] The 3g NaOH dissolved in 30ml of deionized water, followed by addition of 0.86g (NH 4 ) 2 S 2 O 8 , Stirred for 10min, to give V; V dipped in the solution in the U 20min, rinsed with deionized water several times, dried under a stream of nitrogen to give the W; W into a porcelain boat, min in air at 5 ℃ -1 , Annealed at 150 deg.] C for 2 hours to obtain X-cooled; taken 45mL 10mmol L -1 Agno 3 5ml of anhydrous methanol and mixed uniformly to obtain Y; X-Y is dipped into the solution, a xenon lamp light generator side catalytic irradiation of X, taken 3min after rinsing with deionized water several times the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com