Multidirectional moving chassis of aloft work vehicle of aloft worker platform

A high-altitude work vehicle and high-altitude work technology, which is applied to vehicle components, lifting devices, substructures, etc., can solve the problems of rotation obstruction, inability to send the worktable to the designated position, trouble, etc., and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

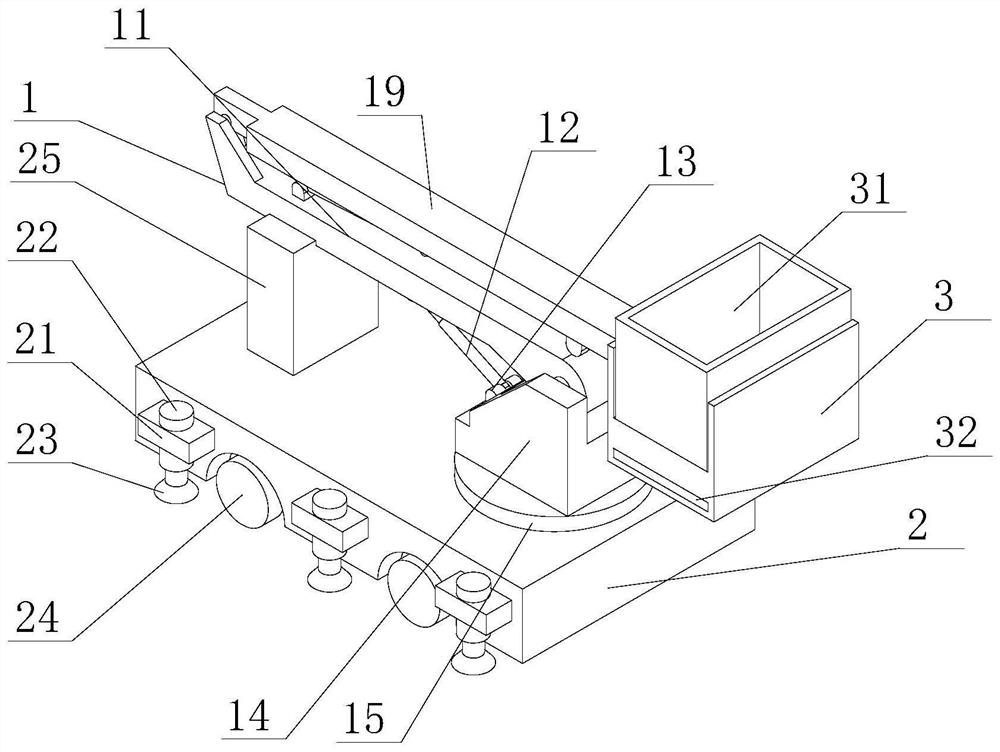

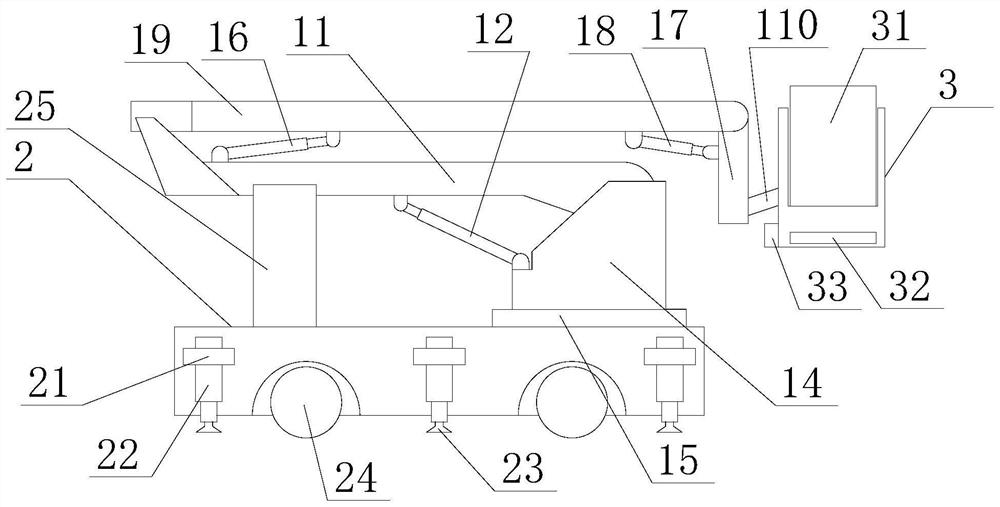

[0022] Embodiment 1: refer to Figure 1-Figure 2 , the bottom of the chassis 2 is provided with mutually symmetrical wheels 24, the quantity of the wheels 24 is provided with four, the two sides of the chassis 2 are movably connected with mutually symmetrical telescopic plates 21, and the quantity of the telescopic plates 21 is provided with six, increasing the chassis 2 Stability, the inside of the telescopic plate 21 is fixedly connected with a leg 22, the bottom of the leg 22 is provided with a grounding plate 23, the top of the grounding plate 23 is fixedly connected with the bottom surface of the leg 22, and the top of the chassis 2 is provided with a recovery support plate 25, recycling The bottom surface of the support plate 25 is fixedly connected to the top of the chassis 2. This design enables the boom 11 to play a certain supporting role when it is recovered, so as to avoid damage to the boom 11 due to inertia. The bottom surface of the slewing support 15 and the top...

Embodiment 2

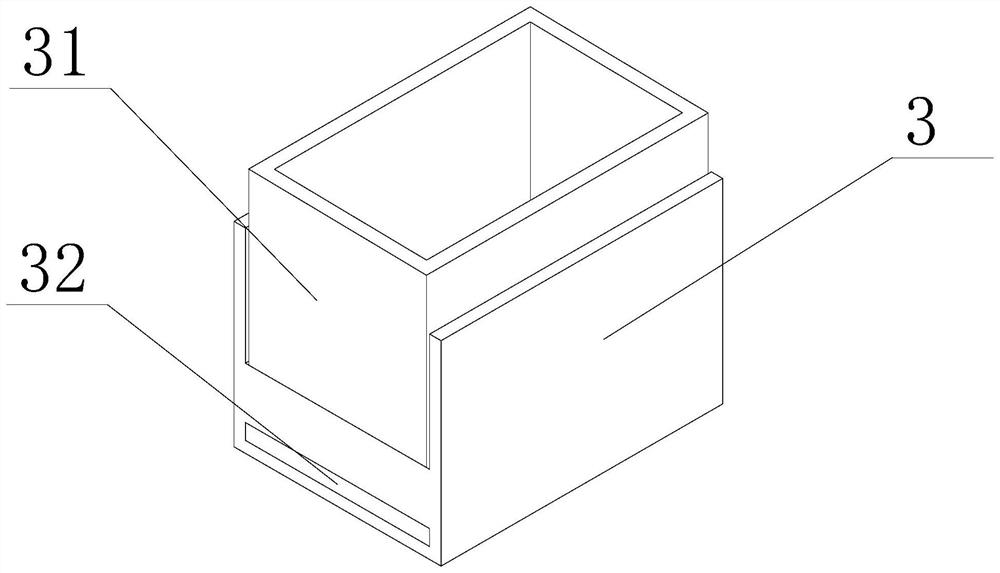

[0023] Embodiment 2: refer to Figure 3-Figure 5, the top of the workbench base 3 is provided with a groove running through the front and the back, the groove of the workbench base 3 is provided with a workbench 31, the bottom surface of the workbench 31 is movably connected with the groove bottom surface of the workbench base 3, and the workbench The bottom surface of 31 is fixedly connected with connecting block one 35, and the bottom of workbench 31 is provided with screw mandrel 39, and the quantity of screw mandrel 39 is provided with two and is vertically distributed up and down, and one end of screw mandrel 39 is connected with the inwall of workbench base 3 by rotation , the other end of screw mandrel 39 is fixedly connected with DC motor one 36, and the bottom of DC motor one 36 is fixedly connected with connection seat, and connection seat is fixedly connected with the inner wall of workbench base 3 by bolt, and DC motor one 36 is connected with work through connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com