Firmly-connected connection fitting

A technology for connecting fittings and firmness, applied in the installation of cables, electrical components, cable accessories, etc., can solve the problems of low practicability, deformation, inconvenient use, etc., and achieve the effect of high practicability, easy use, and quick disassembly of fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

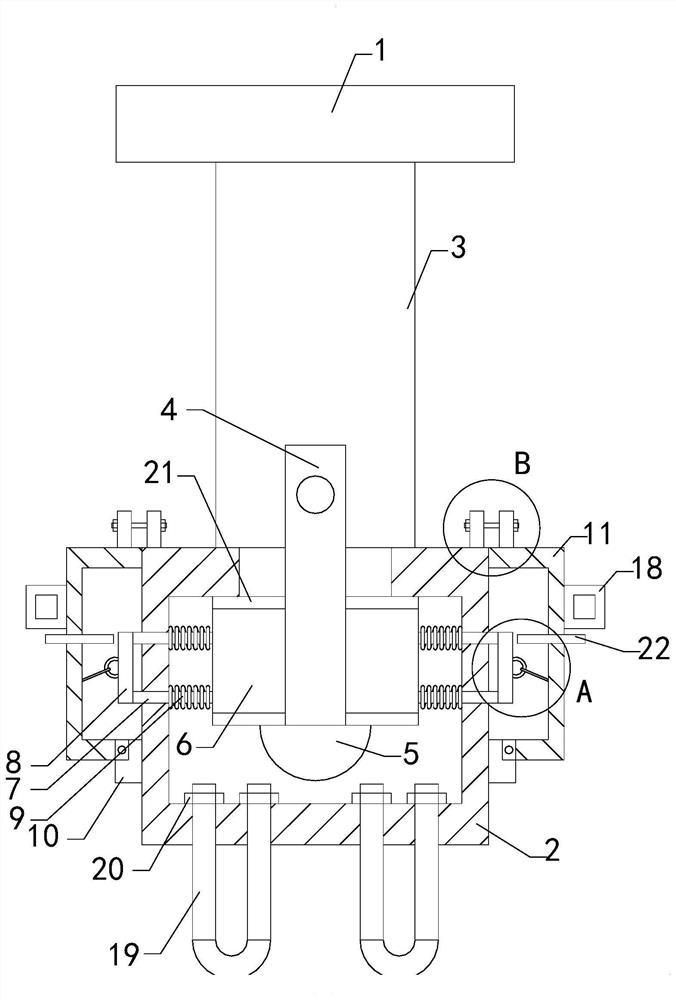

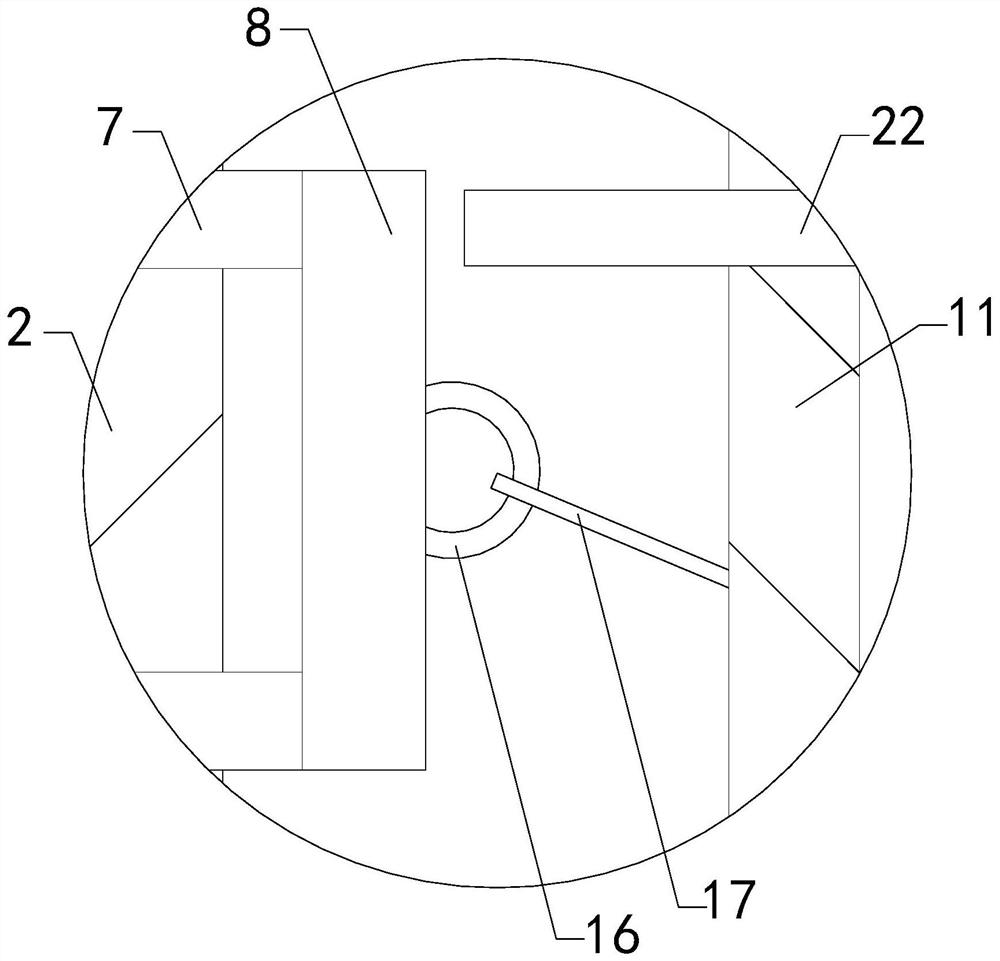

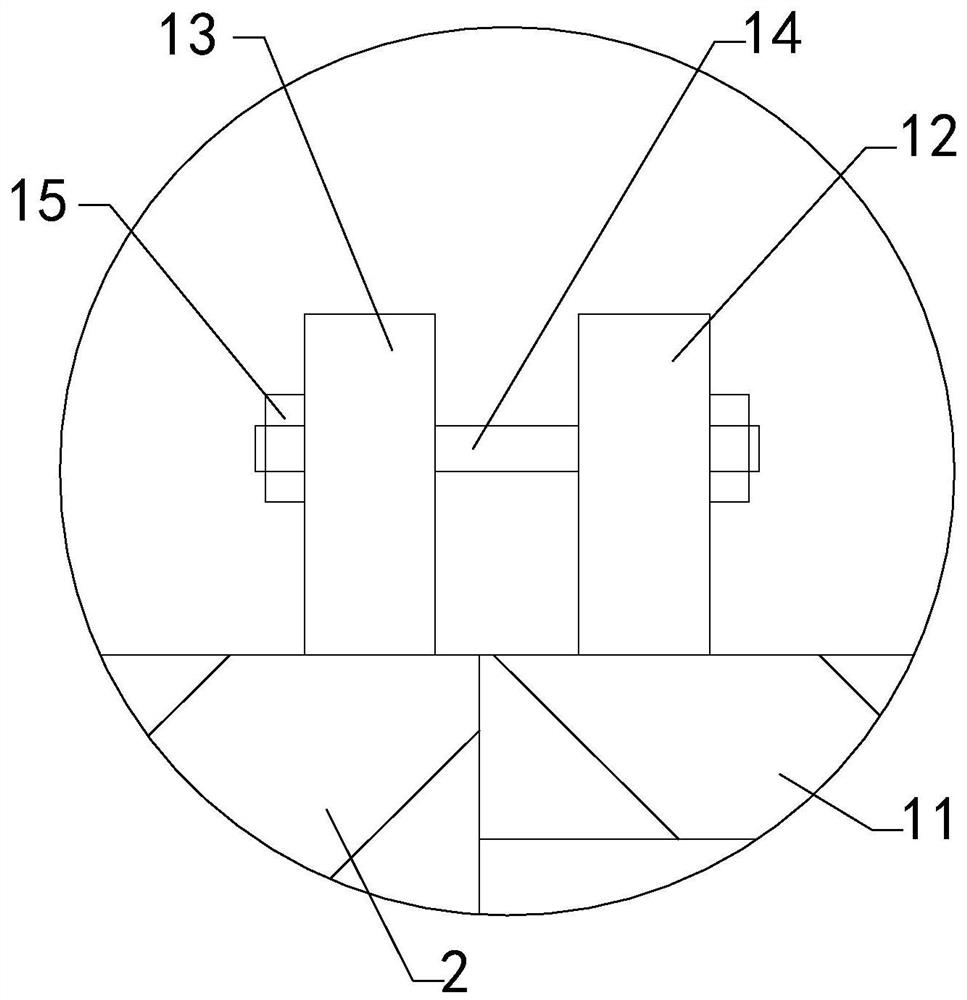

[0025] see Figure 1-5 , a firmly connected connecting fitting, comprising a top plate 1 and a support box 2, an extension plate 3 is fixedly connected to the middle part of the bottom end of the top plate 1, an extension plate 4 is hinged at the bottom of the front end of the extension plate 3, and the support box 2 is provided with a long hole, the bottom end of the extension plate 4 passes through the long hole from the top of the support box 2 and extends to the inside of the support box 2, the bottom end of the extension plate 4 is fixed Connect the limit plate 5, the top of the support box 2 is in contact with the bottom end of the elongated plate 3, and the inside of the support box 2 is symmetrically arranged with a limit device, and the limit device includes a clamping block 6. The bottom end and the top end of the clamping block 6 are fixedly connected with a wear-resistant block 21, the wear-resistant block 21 is a copper block, the upper wear-resistant block 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com