Building engineering construction dust removal device

A technology of dust removal device and construction engineering, which is applied to spray devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of insufficient fixed water spray volume, poor dust reduction effect, waste of water resources, etc., so as to avoid poor dust reduction effect, The effect of flexible use and avoiding water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

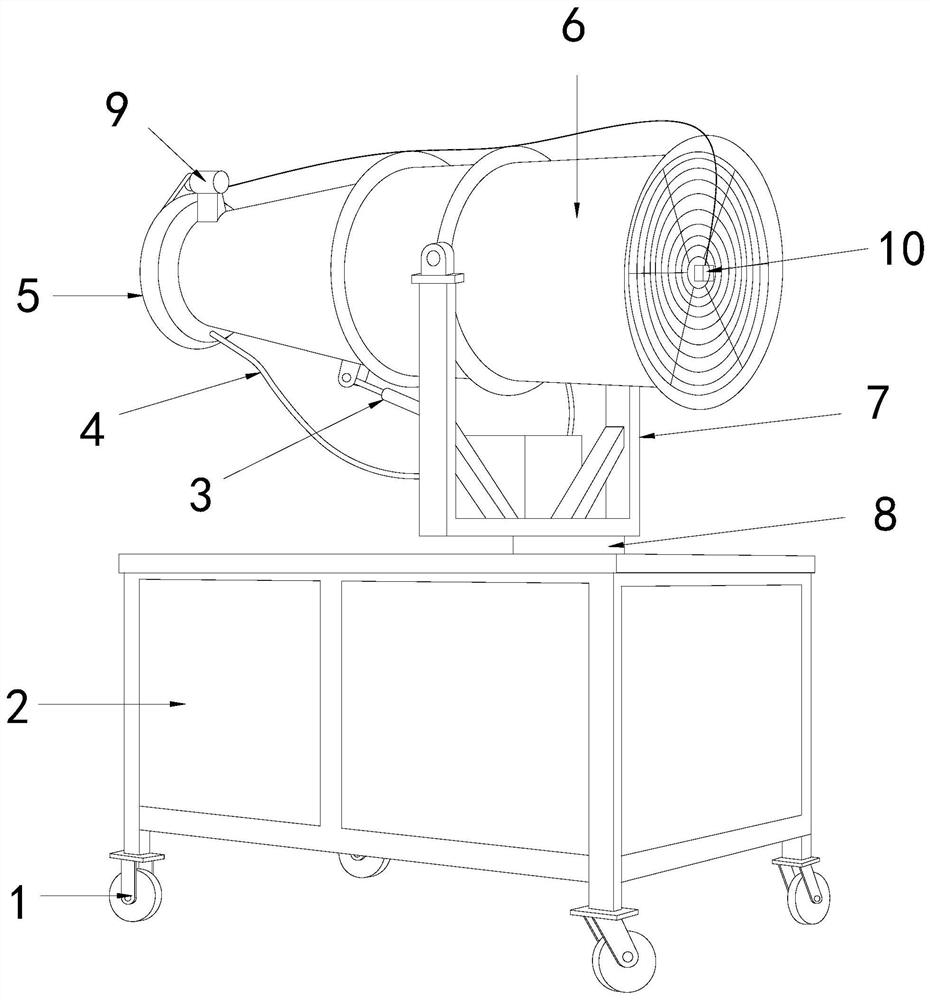

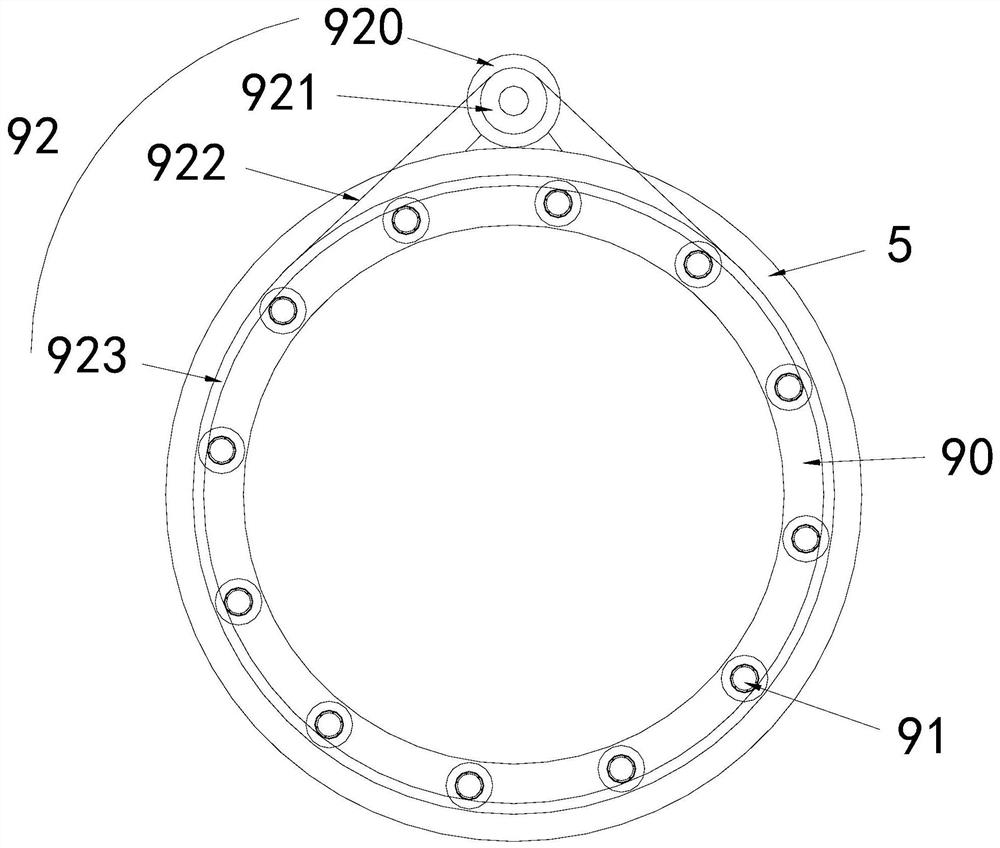

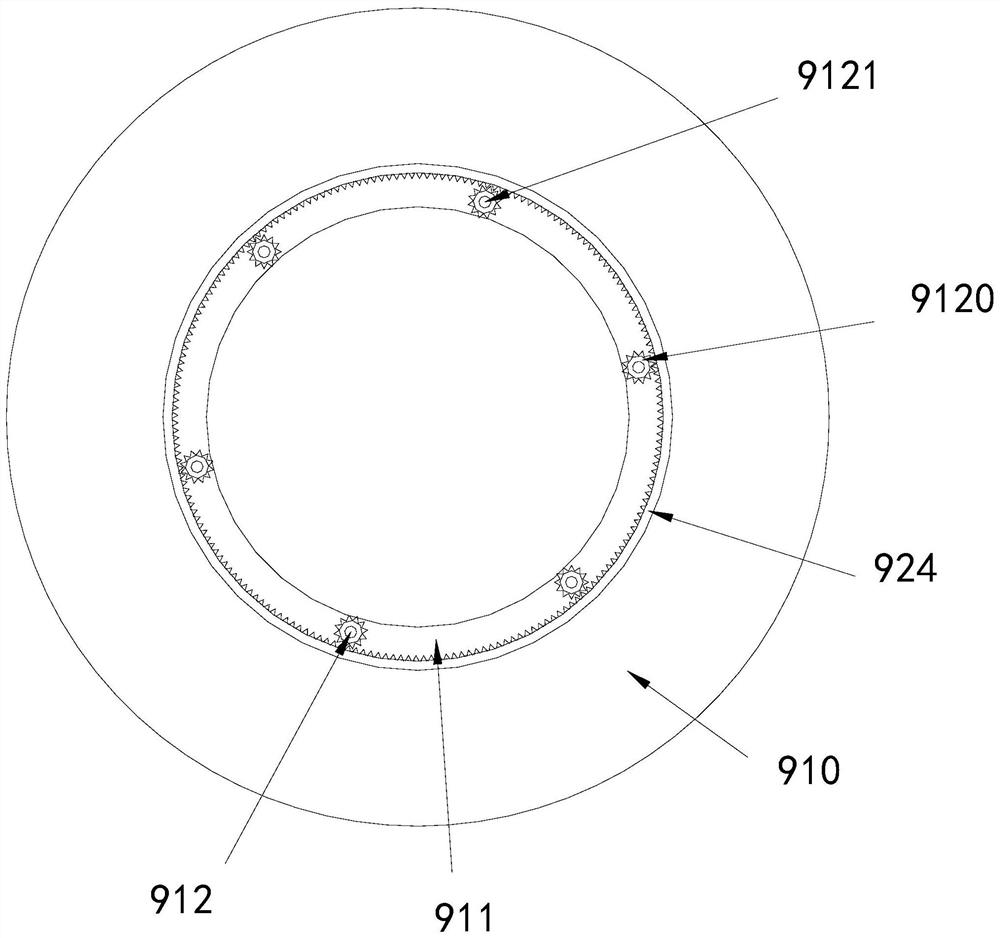

[0027] see Figure 1-5 , the present invention provides a technical solution for a construction dust removal device: its structure includes a roller 1, a base 2, a cylinder 3, a water delivery pipe 4, a nozzle 5, a cylinder 6, a bracket 7, a rotary table 8, an adjustment device 9, and a dust concentration Detector 10, the bottom of the base 2 is equipped with a roller 1, the bottom of the support 7 is installed on the base 2 through a turntable 8, a cylinder 6 is installed on the support 7, and a nozzle is provided at one end of the cylinder 6 5. One end of the barrel 6 provided with the nozzle 5 is connected to the support 7 through the cylinder 3, the nozzle 5 is connected to the base 2 through the water pipe 4, and the end of the barrel 6 connected to the nozzle 5 is installed with an adjustment device 9, the other end of the barrel 6 is an air inlet, the dust concentration detector 10 is installed in the middle of the air inlet, the dust concentration detector 10 is electr...

Embodiment 2

[0030] see Figure 1-5, the present invention provides a technical solution for a construction dust removal device: its structure includes a roller 1, a base 2, a cylinder 3, a water delivery pipe 4, a nozzle 5, a cylinder 6, a bracket 7, a rotary table 8, an adjustment device 9, and a dust concentration Detector 10, the bottom of the base 2 is equipped with a roller 1, the bottom of the support 7 is installed on the base 2 through a turntable 8, a cylinder 6 is installed on the support 7, and a nozzle is provided at one end of the cylinder 6 5. One end of the barrel 6 provided with the nozzle 5 is connected to the support 7 through the cylinder 3, the nozzle 5 is connected to the base 2 through the water pipe 4, and the end of the barrel 6 connected to the nozzle 5 is installed with an adjustment device 9, the other end of the barrel 6 is an air inlet, the dust concentration detector 10 is installed in the middle of the air inlet, the dust concentration detector 10 is electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com